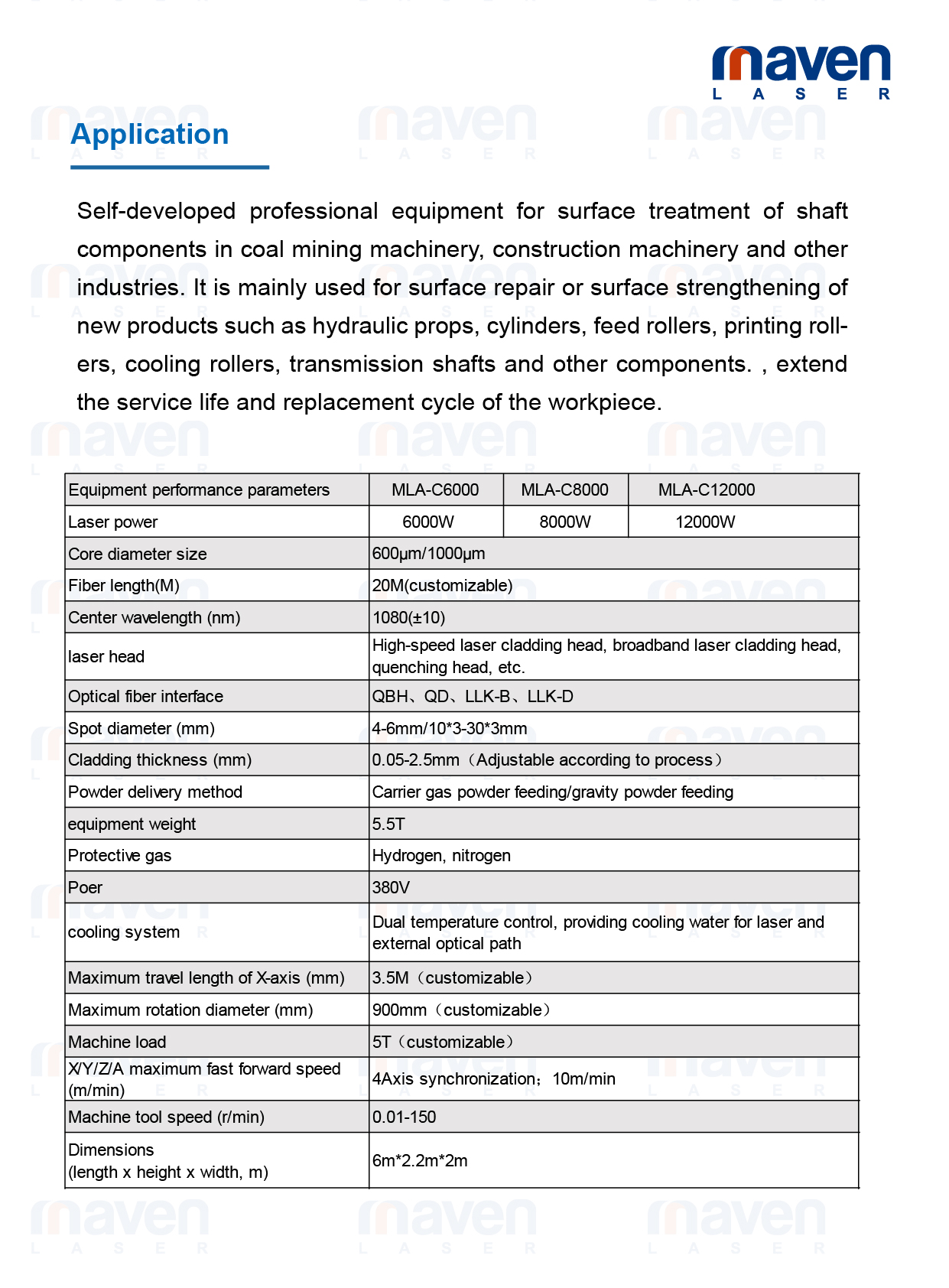

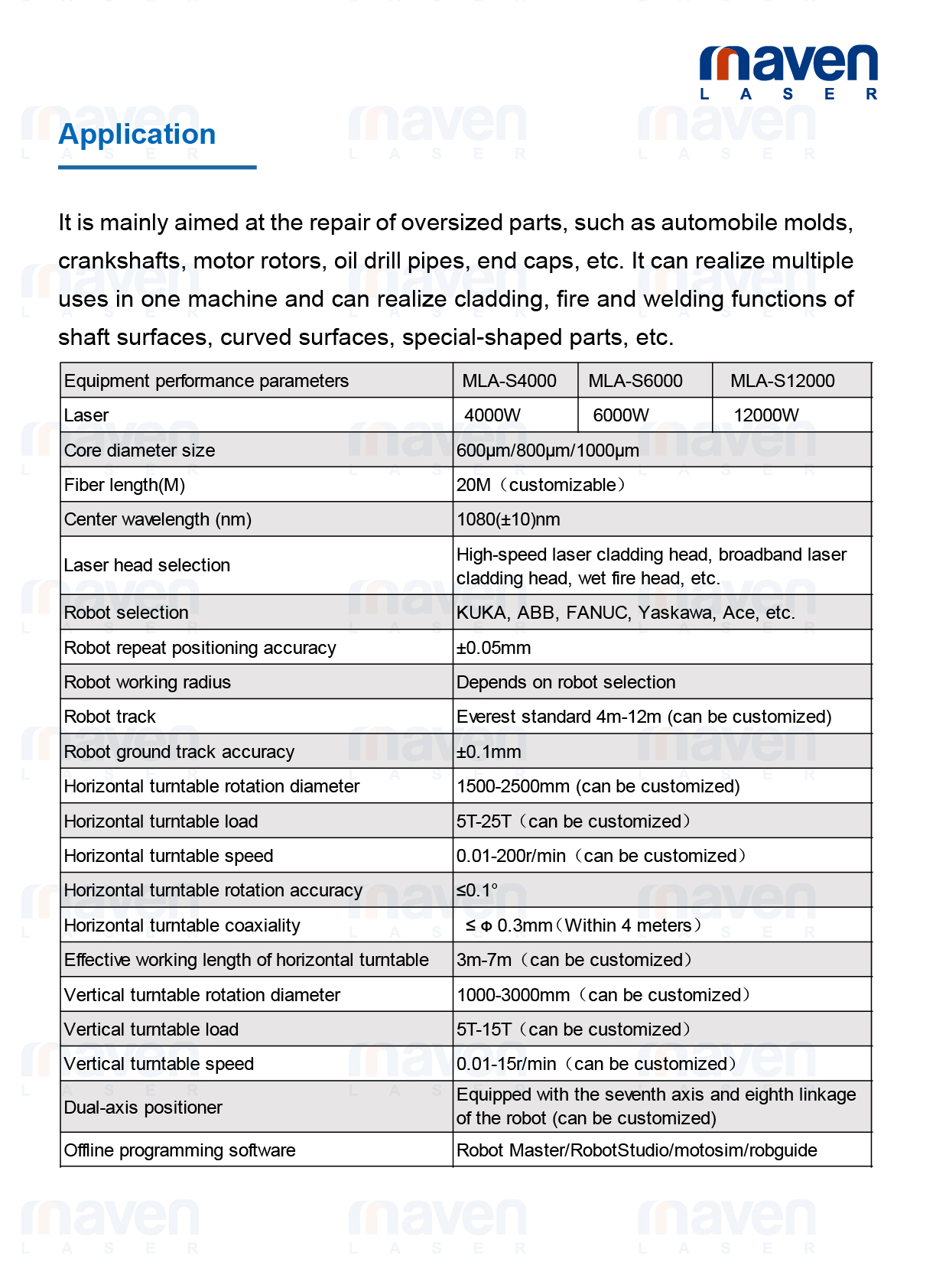

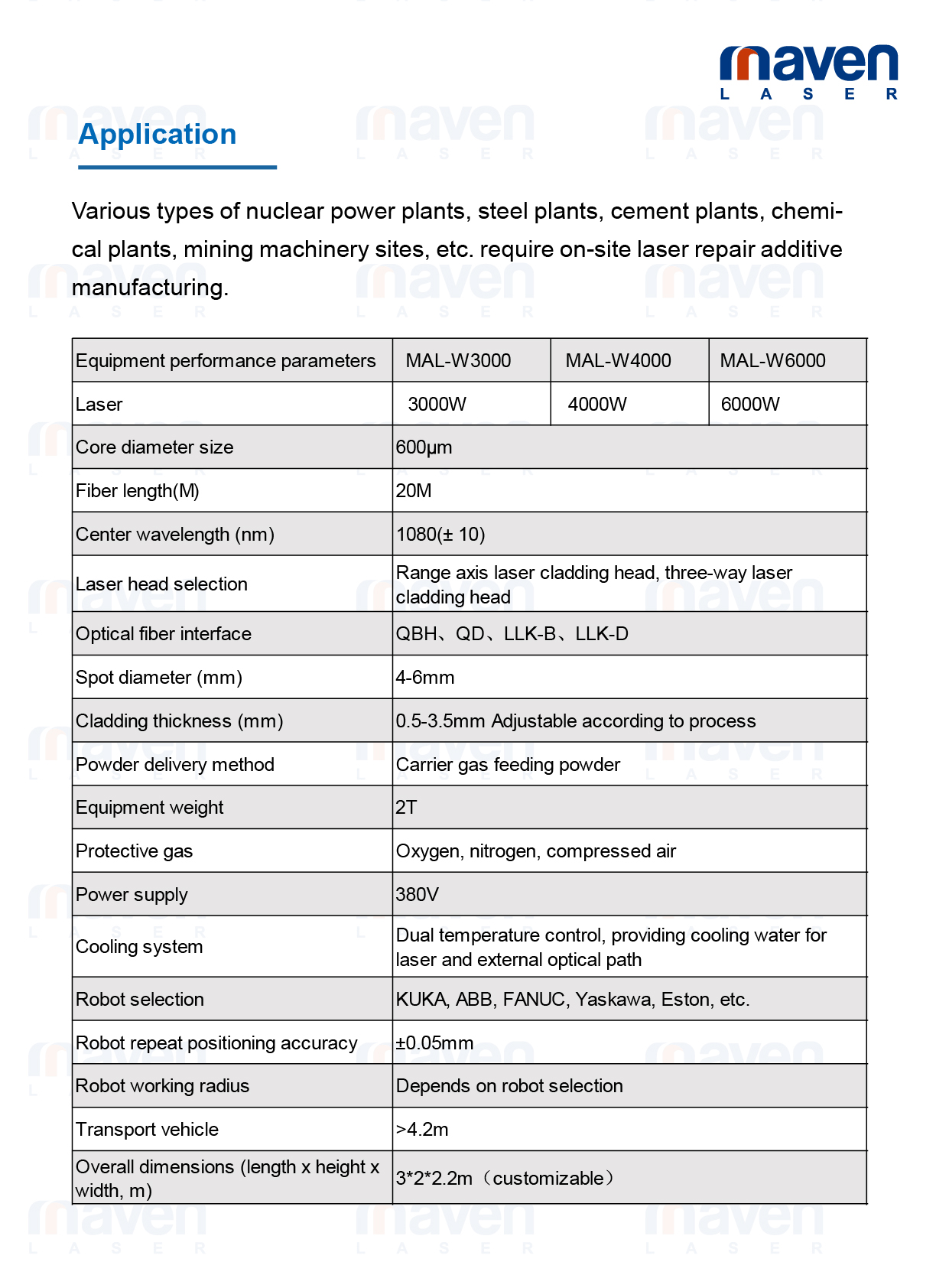

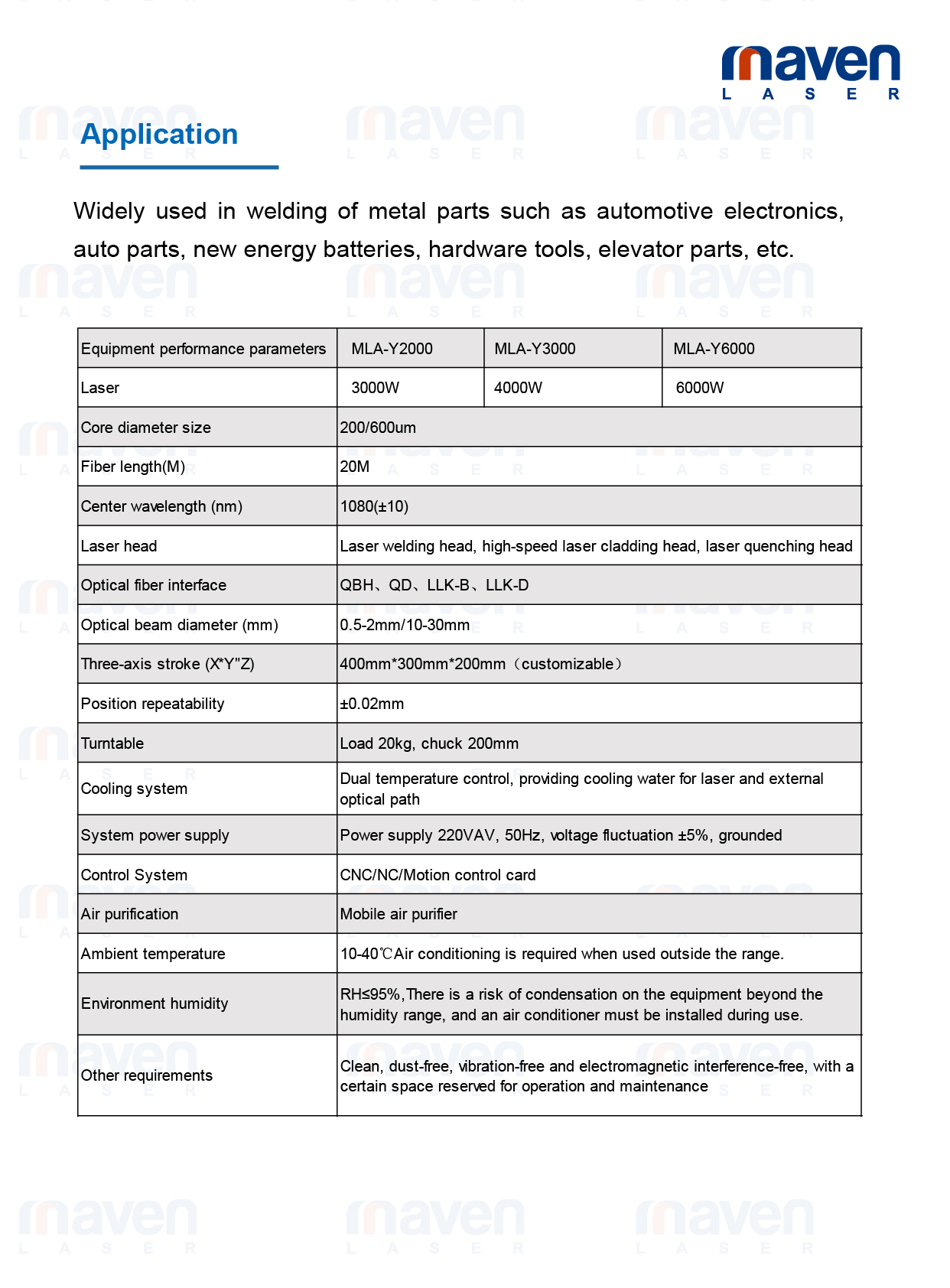

Special machine laser cladding quenching equipment

Laser cladding is a new surface modification technology. it adds claddingmaterial to the surface of the substrate and uses a high-energy-densitylaser beam to fuse it with a thin layer on the surface of the substrate toform a thin layer on the surface of the substrate. lt is a metallurgical bonding additive cladding layer with low dilution rate. Laser melting canachieve dimensional repair or surface strengthening of the workpiece, andimprove the corrosion resistance or wear resistance of the workpiece sur-face, which not only meets the requirements for specific performance ofthe material surface, but also saves a large number of precious elements.Laser cladding technology has been widely used in various aspects suchas aviation, military, petroleum, chemical industry, medical equipment,etc.It can also be used for the remanufacturing of scrap parts, greatlysaving national resources and enterprise production and manufacturingcosts.