Chain machine high speed laser welding

Features

Meet 24 hours use

Input AC power range AC110~260V

Maintenance-free, no consumables

Can be installed inside the chain making machine to save money Can operate in harsh environments with relative humidity up to 90% and temperature up to 50 "C

Product application and sample

Welding materials: gold, silver, copper, stainless steel

True Air-Cooled Lasers

A radiator is a general term for a series of devices used to conduct and release heat. By calculating the heat generated when the laser works at full power, design the area of the radiator and the air duct. With the DC PWM speed control fan, it can receive the air flow more evenly and smoothly, and take the heat away more evenly.

True Air-Cooled Lasers

It can be used with various types of chain weaving machines to efficiently process different styles of necklaces

Chain machine high speed laser welding

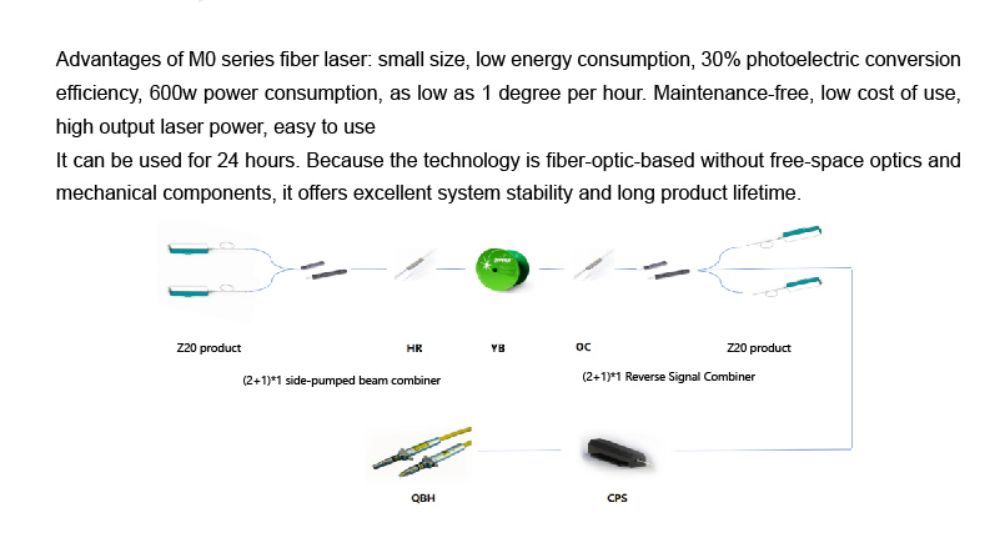

Advantages of M0 series fiber laser: small size, low energy consumption, 30% photoelectric conversion efficiency, 600w power consumption, as low as 1 degree per hour. Maintenance-free, low cost of use, high output laser power, easy to use

It can be used for 24 hours. Because the technology is fiber-optic-based without free-space optics and mechanical components, it offers excellent system stability and long product lifetime.

As a photoelectric combination product, the stability and reliability of electronic control is very important for QCW lasers. The laser has three conversion processes to finally obtain a high-quality laser beam output.

①The 220v mains power is converted into various levels of voltages to drive the pumping source through the power supply.

②The pump source converts electrical energy into pump light.

③The pump light is amplified by the resonant cavity to output laser light. The entire control system requires the combination of hardware and software.

The optical path is precisely and effectively controlled.