new type of welding method pillow plate fully automatic continuous laser welding machine for Single Double embossed plates

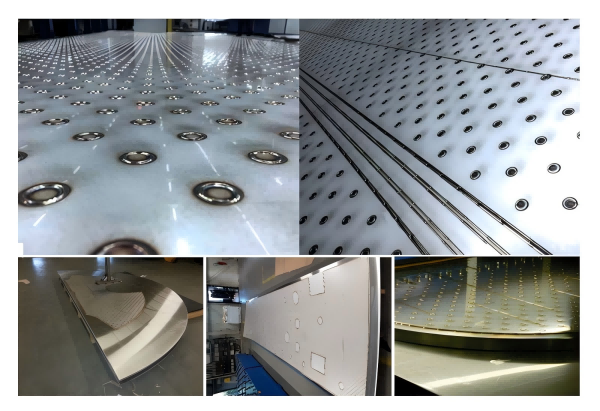

Pillow Plate Laser Welding Machine

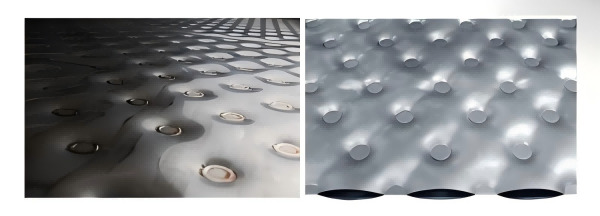

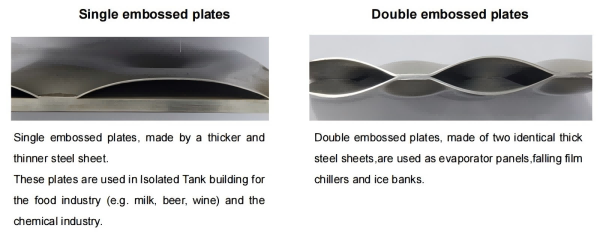

Pillow Plates Head Exchanger

The Pillow plate heat transfer plate is a component of the heat exchanger that mainly performs heat transfer.

According to the different fluid media, the material of the heat transfer plate is different, and most of them are made of stainless steel and titanium.

The Pillow Plate heat transfer plate is processed by fully automatic continuous laser welding and forming technology.

The principle is to use laser to fully weld two stainless steel plates and form bulging, which is suitable for the heat exchange field of various materials.

Its special pillow structure creates a turbulent state in the fluid, achieving heat transfer, and has many characteristics such as dust resistance, high temperature and high pressure resistance, and easy cleaning.

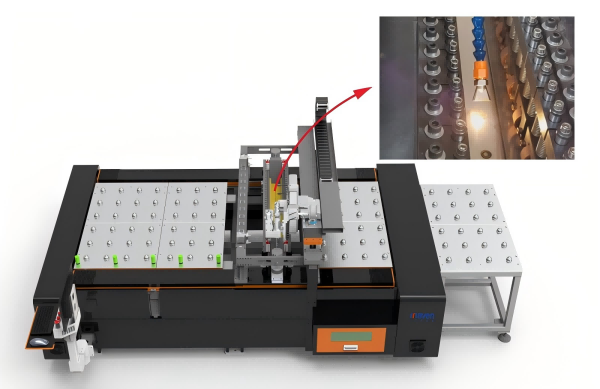

Fully automatic continuous laser welding is a new type of welding method, which is generally composed of a “welding host” and a “welding workbench”.

The laser beam is coupled to an optical fiber, and after long-distance transmission, it is processed into parallel light and focused on the workpiece for continuous welding.

Due to the continuity of the light output, the welding effect is more firm, and the weld seam is finer and more beautiful.

According to the different needs of different industries, this laser welding equipment can match the appearance and workbench according to the production site, and achieve automated operations, fully meeting the needs of users in different industries.

The Machine Advantages

Continuous fiber laser welding machine has become a popular product in the welding field due to its increasing level of intelligence, and is particularly favored in the high-density welding industry.

In addition to achieving the effects of fast welding speed, minimal deformation, and no bubbles that ordinary welding machines can achieve, it also has the following advantages:

1. Continuous fiber laser welding machine can use non-contact welding for parts that are difficult to access for welding, which is more flexible in operation;

2. Combined with CCD camera monitoring system, it is conducive to positioning and easy to observe the welding process.

The energy distribution of the welding spot is uniform, ensuring the beauty and performance of the welded workpiece;

3. Assist enterprises in realizing automated factories that can process and produce multiple beams of light, enabling mass production of products and highlighting the advantage of high output ratio among products in the same series;

4. The laser of the laser welding machine is made of imported materials and has a service life of up to 10 years or more.

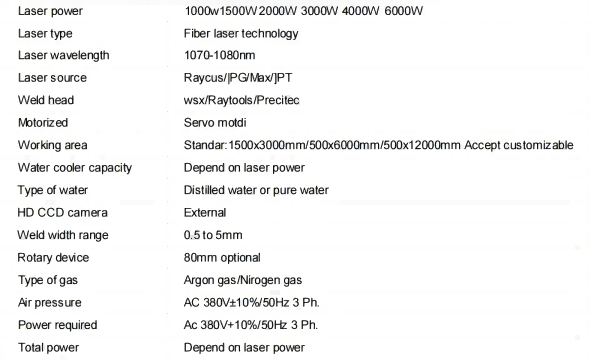

Technical Parameters

Weld Samples Display

Application Scenarios

Write your message here and send it to us