The application of AI technology in the field of welding is promoting the intelligence and automation of the welding process, improving production efficiency and product quality.

The application of AI in welding is mainly reflected in the following aspects:

Welding quality control

The application of AI technology in welding quality control is mainly reflected in welding quality inspection, welding defect identification, and welding process optimization. These applications not only improve the accuracy and speed of welding, but also significantly improve production through real-time monitoring and intelligent adjustment. efficiency and product quality. Here are some key applications of AI technology in welding quality control:

Welding quality inspection

Welding quality inspection system based on machine vision and deep learning: This system combines advanced computer vision and deep learning algorithms to monitor and evaluate the quality of welds during the welding process in real time. By capturing details of the welding process with high-speed, high-resolution cameras, deep learning algorithms can learn and identify welds of different qualities, including welding defects, cracks, pores, etc. This system has a certain degree of adaptability and can adapt to different process parameters, material types and welding environments, so as to be better suited to various welding tasks. In practical applications, this system is widely used in automotive manufacturing, aerospace, electronic manufacturing and other fields. By realizing automated quality inspection, this system not only improves the efficiency of the welding process, but also ensures a high level of weld quality and reduces the defective rate in manufacturing.

Welding defect identification

Zeiss ZADD automatic defect detection technology: AI models are used to help users quickly solve quality problems, especially in porosity, glue coating, inclusions, welding paths and defects.

Deep learning-based weld image defect recognition method: Deep learning technology is used to automatically identify defects in X-ray weld images, improving the accuracy and efficiency of detection.

Welding parameter optimization

Process parameter optimization: AI algorithms can optimize process parameters such as welding current, voltage, speed, etc. based on historical data and real-time feedback to achieve the best welding effect. Adaptive control: By monitoring various parameters during the welding process in real time, the AI system can automatically adjust the welding conditions to cope with material and environmental changes.

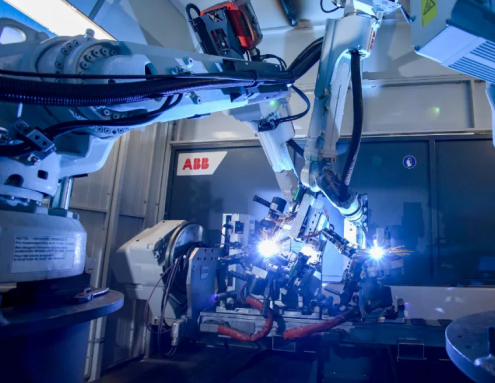

Welding Robot

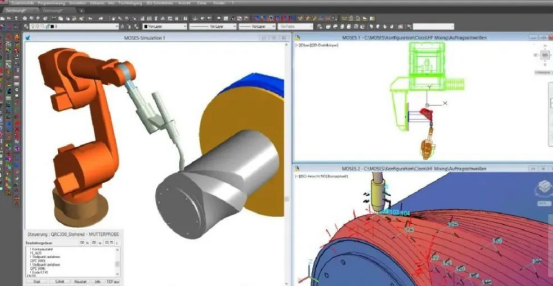

Path planning: AI can help welding robots plan complex paths and improve welding efficiency and accuracy.

Intelligent operation: Through deep learning, welding robots can identify different welding tasks and automatically select appropriate welding processes and parameters.

Welding data analysis

Big data analysis: AI can process and analyze large amounts of welding data, discover hidden patterns and trends, and provide a basis for improving welding processes.

Predictive maintenance: By analyzing the operating data of equipment, AI can predict the failure of welding equipment, perform maintenance in advance, and reduce downtime.

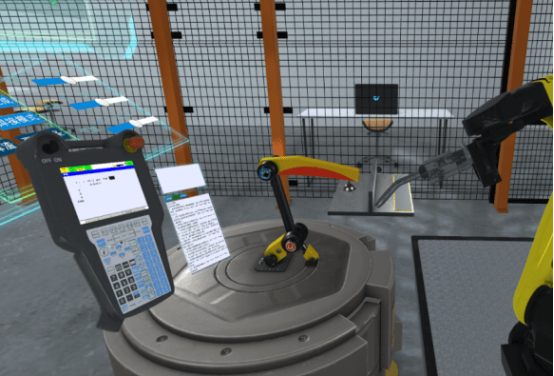

Virtual Simulation and Training

Welding simulation: Using AI and virtual reality technology, the real welding process can be simulated for operation training and process verification. Training optimization: Through AI analysis of welder operation data, personalized training suggestions are provided to improve welding skills.

Future Trends

Improved automation: With the rapid development of artificial intelligence and robotics, intelligent welding equipment will achieve a higher degree of automation and realize completely unmanned or less-manned welding operations.

Data management and monitoring: Intelligent welding equipment will have data collection and remote monitoring functions, and transmit information such as welding parameters, process data, and equipment status to the remote control center or end users in real time through the cloud platform.

Intelligent welding process optimization: Intelligent welding equipment will optimize the welding process through integrated intelligent algorithms to reduce welding defects and deformation.

Multi-process integration: Intelligent welding equipment will integrate different welding processes and technologies to achieve multi-functional and multi-process applications.

Overall, the application of AI in welding has greatly improved welding quality and efficiency, while reducing costs and labor intensity. With the continuous advancement of technology, the application of AI in the field of welding will become more extensive and in-depth.

Post time: Aug-14-2024