In the ever-evolving world of jewelry manufacturing, precision and efficiency are crucial.

The introduction of advanced technology has revolutionized the way jewelers create and repair intricate jewelry.

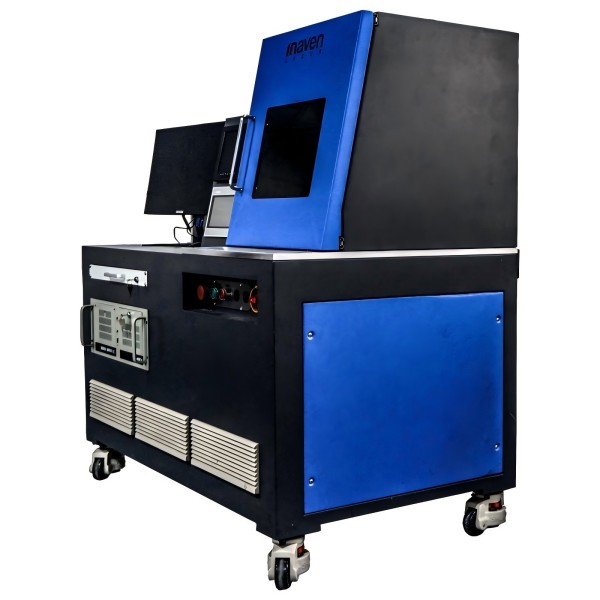

Among these innovations, automatic laser welding machines stand out as game-changing machines, especially for the jewelry industry.

Designed to meet the unique needs of jewelers, this machine provides unparalleled precision and speed during the welding process.

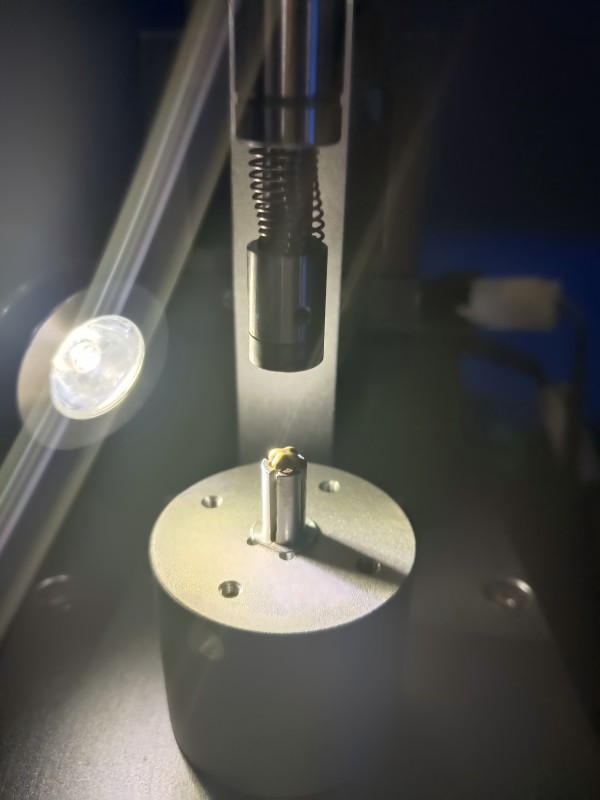

Laser welding machines for the jewelry industry are designed for the fine processing of fine materials.

Traditional soldering methods are often unable to handle the intricate designs and fine details of high-end jewelry.

However, with the advent of laser technology, jewelers can now achieve seamless joins and repairs without compromising the integrity of the jewelry.

The precision of laser welding allows for minimal heat input, which is crucial when working with precious metals and gemstones.

This means the risk of damaging surrounding materials is significantly reduced, ensuring the final product retains its beauty and value.

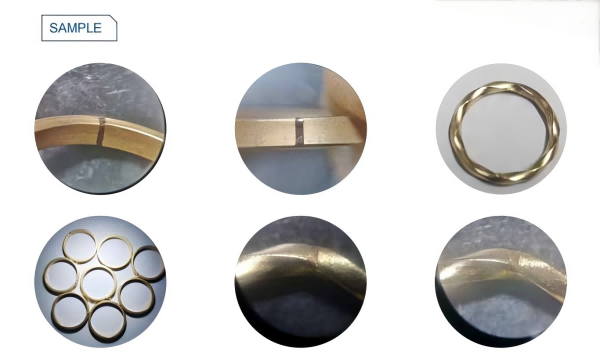

One of the outstanding features of the automatic laser welding machine is its ability to perform edge sealing with amazing efficiency.

Jewelry laser welded edge sealers are specifically designed to create strong, invisible seams that enhance the overall beauty of your jewelry.

This is especially important for jewelry that requires a perfect finish, such as rings, bracelets, and necklaces.

The machine’s advanced technology allows for quick adjustments to laser settings, allowing jewelers to tailor the welding process to the specific requirements of each piece of jewelry.

In addition, the automated functions of laser automatic welding machines simplify the production process. Jewelers can program machines to perform repetitive tasks with consistent results, freeing up valuable time to design and create.

Not only does this increase productivity, it also reduces the possibility of human error, which can be detrimental in the high-risk world of jewelry making.

The ability to automate soldering tasks means jewelers can focus on what they do best – creating stunning pieces that captivate their customers.

In addition to efficiency and precision, laser welding machines for the jewelry industry are also very easy to use.

Many models feature intuitive interfaces that allow operators to easily navigate settings and make adjustments on the fly.

This ease of use ensures that even those who may not have extensive technical training can operate the machine effectively, making it a valuable addition to any jewelry workshop.

The benefits of introducing laser automatic welding machines into the jewelry industry are manifold.

Not only does it improve the quality of the final product, it also positions the company as an innovation leader in the industry.

As consumers increasingly seek unique and high-quality pieces, jewelers investing in advanced technology will be better able to meet these demands.

In summary, automatic laser welding machines designed specifically for the jewelry industry represent a significant advancement in jewelry manufacturing.

With its precision, efficiency and user-friendly design, it enables jewelers to create beautiful pieces that will stand the test of time.

As the industry continues to evolve, the adoption of this technology is critical for those who wish to thrive in a highly competitive market.

The future of jewelry making is bright, and laser welding is at the forefront of this exciting transformation.

Post time: Nov-28-2024