In the ever-evolving world of industrial manufacturing, the need for efficient, high-quality production methods has never been greater.

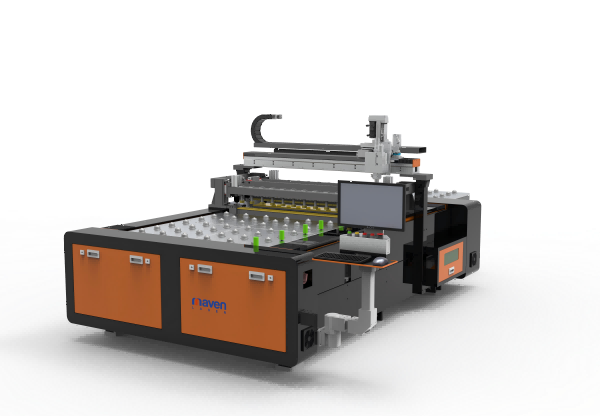

One of the most innovative advancements in this field is the continuous fiber laser welding machine, especially when applied to the production of pillow plate heat transfer plates.

This combination of technology and design is revolutionizing the way the industry adopts heat transfer solutions.

Learn About Pillow Plate Heat Transfer Plates

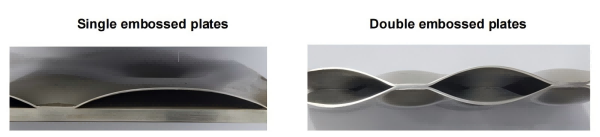

A pillow plate heat transfer plates is a common heat exchanger used in systems such as air conditioning, refrigeration equipment and cooling towers.

Its working principle is to use the two-phase flow and heat transfer principle to transfer heat.

The condensing plate consists of a series of parallel metal plates.

One side of the plate is used to transfer the amount of condensing agent, called the hot side;

The other side of the plate is used to transfer the heat of the material being cooled, called the cold side.

The role of continuous fiber laser welding

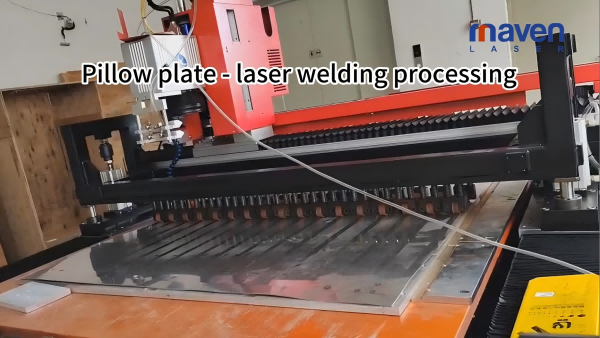

Continuous fiber laser welding machine plays a vital role in the manufacturing of pillow plate heat transfer plates.

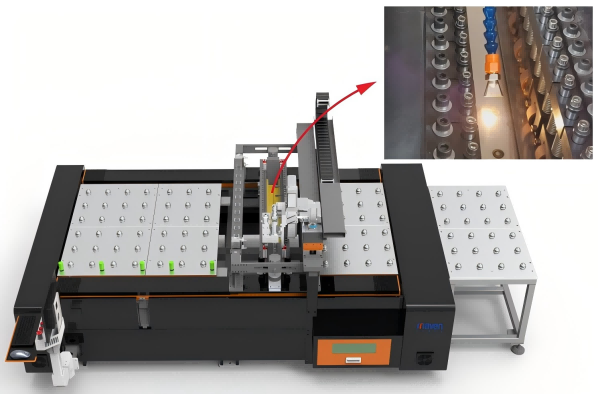

This advanced welding technology utilizes a continuous fiber laser beam to create precise and strong welds.

Compared with traditional welding methods, which are time-consuming and may damage the integrity of the material, fiber laser welding has several advantages:

1) Precision and Quality: High-intensity laser beams enable extremely precise welding, ensuring the intricate design of the bolster remains intact.

This precision is critical to achieving optimal heat transfer efficiency.

2) Speed and Efficiency: Continuous fiber laser welding is significantly faster than traditional welding methods.

This speed not only increases productivity but also reduces operating costs, making it an attractive option for manufacturers.

3) Minimum Heat Affected Zone: The focusing characteristics of the laser minimize the heat affected zone, thereby reducing the risk of deformation or damage to surrounding materials.

This property is particularly important in the production of heat transfer plates, where material integrity is crucial.

4) Versatility: Continuous fiber laser welding machines can weld a variety of materials, including stainless steel and aluminum, which are commonly used for pillow plate heat transfer plates.

This versatility allows manufacturers to adapt to different project requirements without having to invest in multiple welding systems.

Industry Application

The integration of continuous fiber laser welding machines in the production of pillow plate heat transfer plates has had a profound impact on various industries.

For example, in the food and beverage industry, these plates are crucial for pasteurization and cooling processes, for which efficiency and hygiene are crucial.

In the chemical industry they are used in reactors and heat exchangers where reliable performance cannot be ignored.

Additionally, the HVAC industry benefits from the enhanced thermal properties of pillow panels, allowing for more efficient heating and cooling systems.

As industries become increasingly focused on sustainability, the ability to produce high-quality heat transfer solutions and reduce energy consumption becomes a significant competitive advantage.

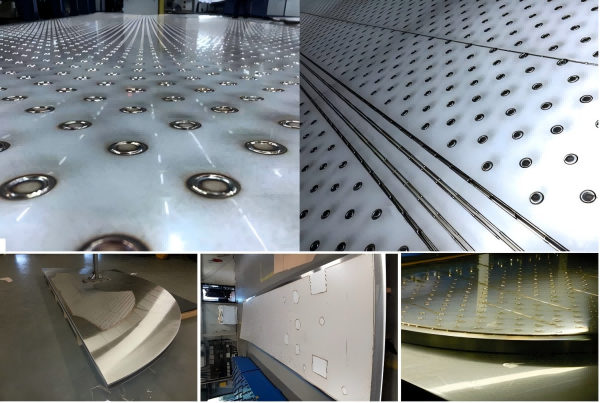

Some Welding Example

In conclusion

Continuous fiber laser welding machines represent a major leap forward in pillow plate heat transfer plate manufacturing.

By combining precision, speed and versatility, the technology not only improves the quality of the final product but also helps improve the overall efficiency of industrial processes.

As industries continue to seek innovative solutions to meet their heat transfer needs, the synergy between fiber laser welding and bolster technology will play a key role in shaping the future of manufacturing.

Post time: Oct-17-2024