As the carrier of other parts of the car, the manufacturing technology of the car body directly determines the overall manufacturing quality of the car. In the process of auto body manufacturing, welding is an important production process. The welding technologies currently used for auto body welding mainly include resistance spot welding, molten inert gas shielded welding (MIG welding) and molten active gas shielded arc welding (MAG welding) as well as laser welding.

As an advanced welding technology with optical-mechanical integration, laser welding technology has the advantages of high energy density, fast welding speed, low welding stress and deformation, and good flexibility compared with the traditional auto body welding technology.

The car body structure is complex, and the body parts are mainly thin-walled and curved components. Auto body welding is faced with welding difficulties such as variations in body materials, varying thickness of body parts, diverse welding trajectories and joint forms. In addition, automotive body welding has high requirements on welding quality and welding efficiency.

Based on suitable welding process parameters, laser welding can ensure high fatigue strength and impact toughness of key auto body parts when welding, thus ensuring the quality and service life of body welding. Laser welding technology can adapt to the welding of auto body parts with different joint forms, different thicknesses and different material types, meeting the demand for flexibility in auto body manufacturing. Therefore, laser welding technology is an important technical means to achieve high-quality development of the automotive industry.

Laser welding process for automotive bodies

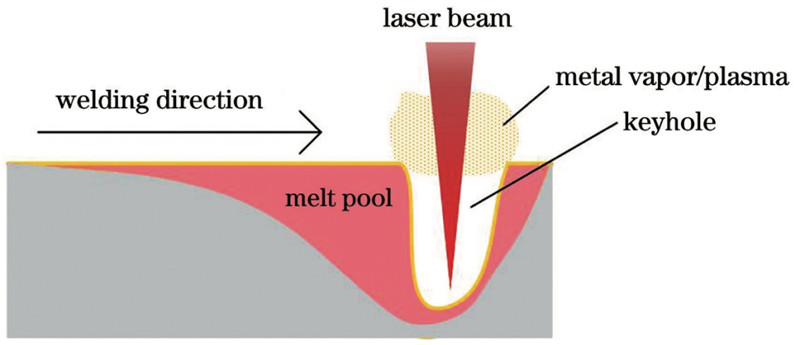

Laser deep fusion welding process principle: When the laser power density reaches a certain level, the material surface vaporizes, thus forming a keyhole. When the metal vapor pressure inside the hole reaches dynamic equilibrium with the static pressure and surface tension of the surrounding liquid, the laser can irradiate through the keyhole to the bottom of the hole, and with the movement of the laser beam, a continuous weld is formed. In the laser deep fusion welding process, there is no need to add auxiliary flux or filler to weld the workpiece's own material into one.

The weld seam obtained by laser deep fusion welding is generally smooth and straight with small deformation, which is conducive to improving the manufacturing accuracy of auto body. The tensile strength of the weld is high, which ensures the welding quality of the auto body. The welding speed is fast, which is conducive to improving the welding production efficiency.

In the auto body welding process, the use of laser deep fusion welding process can significantly reduce the number of parts, molds and welding tooling, thus reducing the dead weight of the body and production costs. However, the laser deep fusion welding process is less tolerant to the assembly gap of the parts to be welded, and the assembly gap needs to be controlled between 0.05 and 2 mm. If the assembly gap is too large, welding defects such as porosity will occur.

Current research shows that in the auto body welding of the same material, by optimizing the process parameters of laser deep-fusion welding, it is possible to obtain a weld with good surface formation, fewer internal defects and excellent mechanical properties. The excellent mechanical properties of the weld can meet the use requirements of the auto body welded components. However, in the auto body welding, aluminum alloy-steel as the representative of the heterogeneous metal laser deep fusion welding process is not mature, although by adding a transition layer can obtain excellent performance of the weld, but the different transition layer materials on the IMC layer influence mechanism and its effect on the micro structure of the weld mechanism is not clear, need further in-depth study.

Auto Body Laser Wire Filling Welding Process

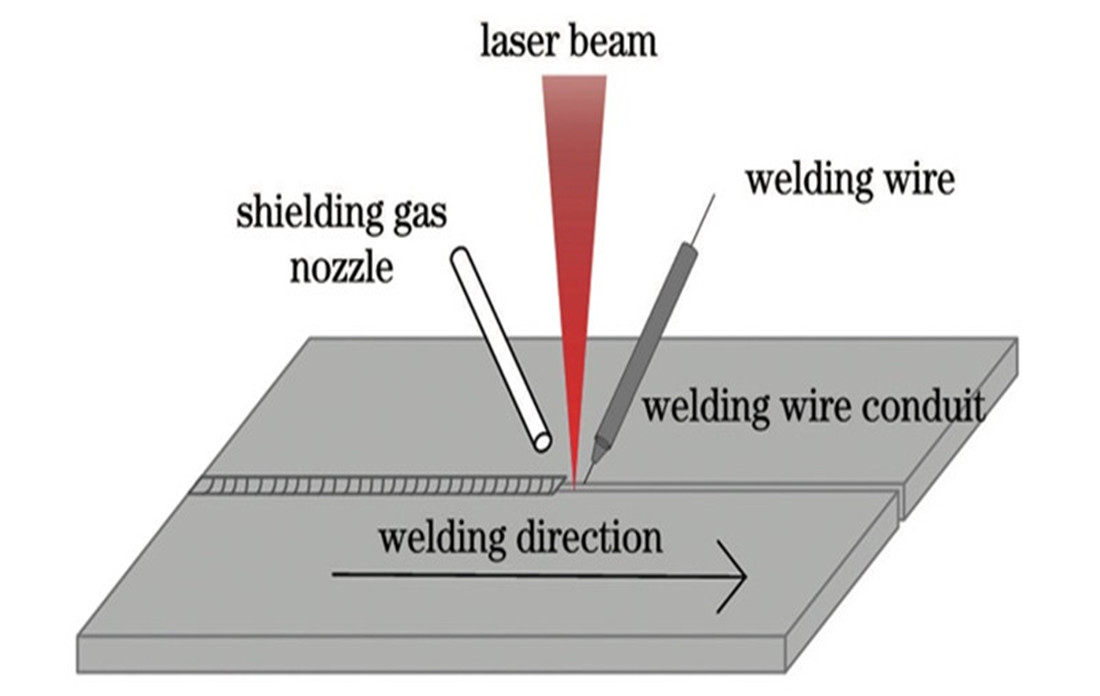

The laser filler welding process is based on the following principle: A welded joint is formed by pre-filling the weld with a specific wire or by feeding the wire simultaneously during the laser welding process. This is equivalent to feeding an approximately homogeneous amount of wire material into the weld pool during laser deep fusion welding. The diagram below shows the laser filler welding process.

Compared with laser deep fusion welding, laser filler welding has two advantages in auto body welding: firstly, it can significantly improve the tolerance of assembly gap between auto body parts to be welded and solve the problem of high bevel gap requirement for laser deep fusion welding; secondly, it can improve the tissue distribution in the weld area by using wires with different composition content, and then regulate the weld performance.

In the process of auto body manufacturing, laser filler welding process is mainly used to weld aluminum alloy and steel parts of the body. Especially in the welding process of aluminum alloy parts of auto body, the surface tension of the molten pool is small, which can easily lead to the collapse of the molten pool, while the laser filler welding process can better solve the problem of molten pool collapse through the melting of the wire in the laser welding process.

Automotive body laser brazing process

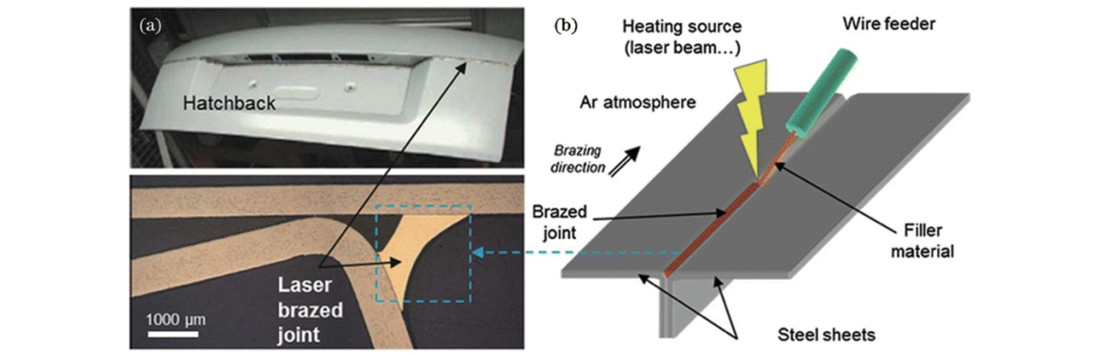

The laser brazing process is based on the following principle: Using a laser as a heat source, the laser beam is focused and irradiated onto the surface of the wire, the wire melts, the melted wire drips down and fills the workpiece to be welded, and metallurgical effects such as melting and diffusion occur between the brazing material and the workpiece, thereby joining the workpiece. Unlike the laser filler welding process, the laser brazing process only melts the wire and not the workpiece to be welded. Laser brazing has good welding stability, but the tensile strength of the resulting weld is low. Figure 3 shows the application of laser brazing process in automotive luggage compartment cover welding

In the process of auto body welding, laser brazing process is mainly used to weld the body parts that do not require high joint strength, such as the welding between the top cover and side surrounds, the welding between the upper and lower part of the luggage compartment cover, etc. The top cover of VW, Audi and other medium and high-end models are all using laser brazing process.

The main defects in laser brazed joints of automobile bodies include edge gnawing, porosity, weld deformation, etc., and the defects can be significantly suppressed by regulating the process parameters and using multi-focus laser brazing process.

Automotive body laser-arc composite welding process

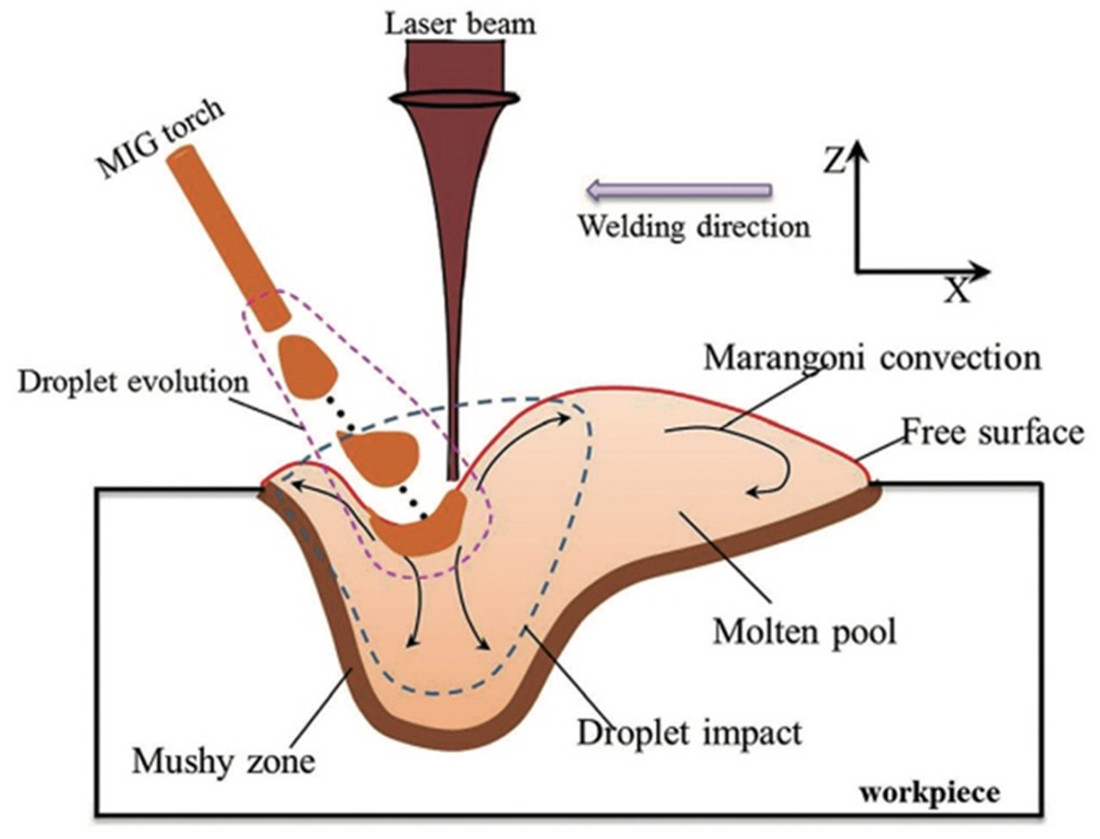

The principle of laser-arc composite welding process is as follows: two heat sources, laser and arc, are used to simultaneously act on the surface of the workpiece to be welded, and the workpiece is melted and solidified to form a weld seam. The diagram below shows the laser-arc welding process.

Laser-arc composite welding combines the advantages of laser welding and arc welding: first, under the action of dual heat sources, the welding speed can be increased, the heat input becomes smaller, the weld deformation is small, maintaining the characteristics of laser welding; second, better bridging ability, assembly gap tolerance is greater; third, the solidification speed of the molten pool becomes slower, which is conducive to the elimination of pores, cracks and other welding defects, improve the organization and performance of the heat-affected zone Fourth, due to the arc, it is able to weld materials with high reflectivity and high thermal conductivity, with a wider range of applied materials.

In the auto body manufacturing process, laser - arc composite welding process is mainly welding body aluminum alloy components and aluminum alloy - steel dissimilar metals, for the assembly gap of the larger parts of the welding, such as the car door part of the location of the welding, this is because the assembly gap is conducive to the laser - arc composite welding bridging performance. In addition, the laser-MIG arc composite welding technology is also applied to the side roof beam position of the Audi body.

In the auto body welding process, laser-arc composite welding has the advantage of large gap tolerance compared to single laser welding, however, laser-arc composite welding requires comprehensive consideration of the relative position of the laser and arc, laser welding parameters, arc parameters and other factors. The heat and mass transfer behavior of the laser-arc welding process is complex, especially the energy regulation of heterogeneous material welding and the mechanism of IMC thickness and tissue regulation is still unclear and requires further strengthening of research.

Other automotive body laser welding processes

Laser deep fusion welding, laser filler welding, laser brazing and laser-arc composite welding and other welding processes have a more mature theory and a wide range of practical applications. As the automotive industry's requirements for body welding efficiency increase and the demand for welding of dissimilar materials in lightweight manufacturing increases, laser spot welding, laser oscillation welding, multi-laser beam welding and laser flight welding have gained attention.

Laser spot welding process

Laser spot welding is an advanced laser welding technology with outstanding advantages of fast welding speed and high welding accuracy. The basic principle of laser spot welding is to focus the laser beam on a point on the part to be welded, so that the metal at that point melts instantly, and by adjusting the laser density to achieve thermal conduction welding or deep fusion welding effect, when the laser beam stops working, the liquid metal refluxes, solidifies and forms a joint.

There are two main forms of laser spot welding: pulsed laser spot welding and continuous laser spot welding. The laser beam in pulsed laser spot welding has a high peak energy, but the action time is short, and is generally used for welding of light metals such as magnesium alloys and aluminum alloys. In continuous laser spot welding, the laser beam has a high average power and a long laser action time, and is mostly used for welding of steel.

In auto body welding, compared with resistance spot welding, laser spot welding has the advantages of non-contact and self-designed spot welding trajectory, which can meet the demand for high-quality welding under different lap gaps of auto body materials.

Laser oscillation welding process

Laser oscillation welding is a new laser welding technology that has been proposed in recent years and has received widespread attention. The principle of this technology is to achieve a fast, orderly and small oscillation of the laser beam by integrating an oscillating mirror into the laser welding head, thus achieving the effect of stirring the beam while moving forward during laser welding.

The main oscillation trajectories in the laser oscillation welding process include: transverse oscillation, longitudinal oscillation, circular oscillation and infinite oscillation. The laser oscillation welding process has significant advantages in auto body welding, as the flow state of the melt pool is significantly changed by the oscillation of the laser beam, so the process can eliminate unfused defects, achieve grain refinement and suppress porosity in the welding of the same auto body material, and improve the problems of insufficient mixing of different materials and poor mechanical properties of the weld seam in the welding of dissimilar auto body materials.

Multi-laser beam welding process

Currently, fiber lasers can be used to divide a single laser beam into multiple laser beams using a beam splitting module installed in the welding head. Multi-laser beam welding is equivalent to applying multiple heat sources in the welding process. By adjusting the energy distribution of the beam, different beams can achieve different functions, such as: the beam with higher energy density is the main beam, responsible for deep melt welding; the sub-beam with lower energy density can clean and preheat the material surface and increase the absorption of laser beam energy by the material.

The multi-laser beam welding process can improve the evaporation behavior of zinc vapor and the dynamic behavior of the melt pool during the welding of galvanized steel sheets, improve the spattering problem and enhance the tensile strength of the weld seam.

Laser flight welding process

Laser flight welding technology is a new laser welding technology with high welding efficiency and autonomous design of the welding trajectory. The basic principle of laser flight welding is that when the laser beam is incident on the X and Y mirrors of the scanning mirror, the angle of the mirror is controlled through autonomous programming to achieve deflection of the laser beam at any angle.

Traditionally, laser welding of auto body mainly relies on the welding robot to drive the laser welding head for synchronous motion to achieve the welding effect. However, the repetitive reciprocating motion of the welding robot severely limits the efficiency of auto body welding due to the large number of welds and the long length of the welds. In contrast, laser flight welding can be achieved within a certain range by simply adjusting the angle of the reflector. Therefore, laser flight welding technology can significantly improve the welding efficiency and has a broad application prospect.

Summary

With the development of the automotive industry, the future of body welding technology will continue to develop in both the welding process and intelligent technology.

Auto body, especially the new energy vehicle body, is developing in the direction of light weight. Lightweight alloys, composite materials and heterogeneous materials will be more widely used in auto body, conventional laser welding process is difficult to meet its welding requirements, so high quality and efficient welding process will become the future development trend.

In recent years, the emerging laser welding process, such as laser swing welding, multi-laser beam welding, laser flight welding, etc., has been in the welding quality and welding efficiency of the initial theoretical research and process exploration. The future needs to be the emerging laser welding process and auto body lightweight materials, heterogeneous materials welding and other scenarios closely combined, the laser beam swing trajectory design, multi-laser beam energy action mechanism and flight welding efficiency improvement and other aspects of in-depth research to explore a mature lightweight auto body welding process.

Auto body laser welding technology is being deeply integrated with intelligent technology, real-time sensing of auto body laser welding status and feedback control of process parameters have a decisive role in welding quality. The current intelligent laser welding technology is mostly used for pre-welding trajectory planning and tracking and post-welding quality inspection. Domestic and foreign research in the detection of welding defects and adaptive regulation of parameters is still in its infancy, and the laser welding process parameters adaptive control technology has not been applied in the auto body manufacturing.

Therefore, for the application of laser welding technology in the auto body welding process characteristics, the future should be developed with advanced multi-sensor core laser welding intelligent sensing system and high-speed high-precision welding robot control system to ensure that the laser welding intelligent technology in real time and accuracy of each link, through the "pre-welding trajectory planning - welding parameters adaptive control post-welding quality online Inspection" link, to ensure high quality and efficient processing.

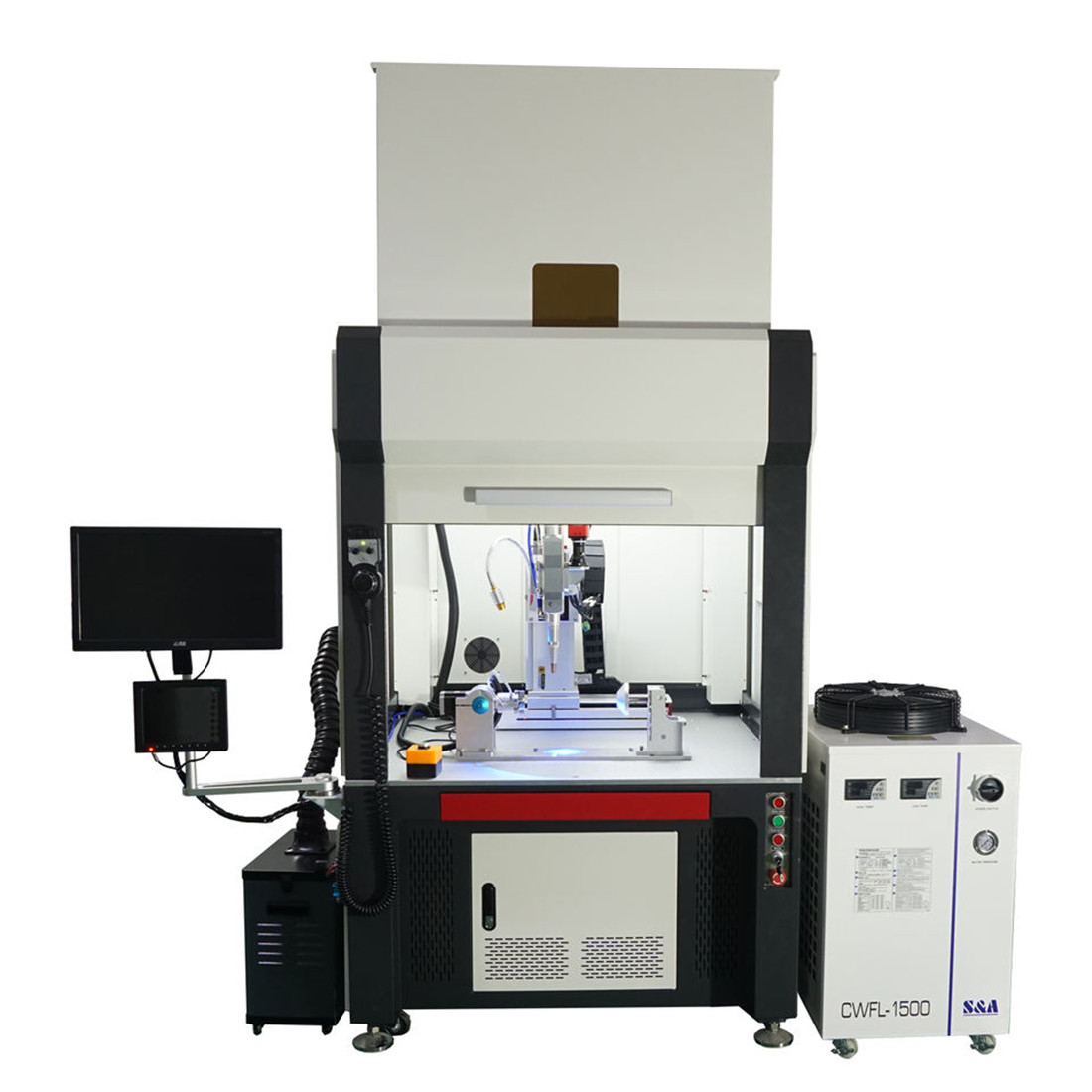

Maven laser automation company focus on laser industry for 14 years, we specialize in laser welding, we have robotic arm laser welding machine, Table Automatic Laser Welding machine, Handheld Laser welding machine, in addition, we also have laser welding machine, laser cutting machine and laser marking engraving machine, we have a lot of laser welding solution cases, if you are interested you can always contact us.

Post time: Dec-09-2022