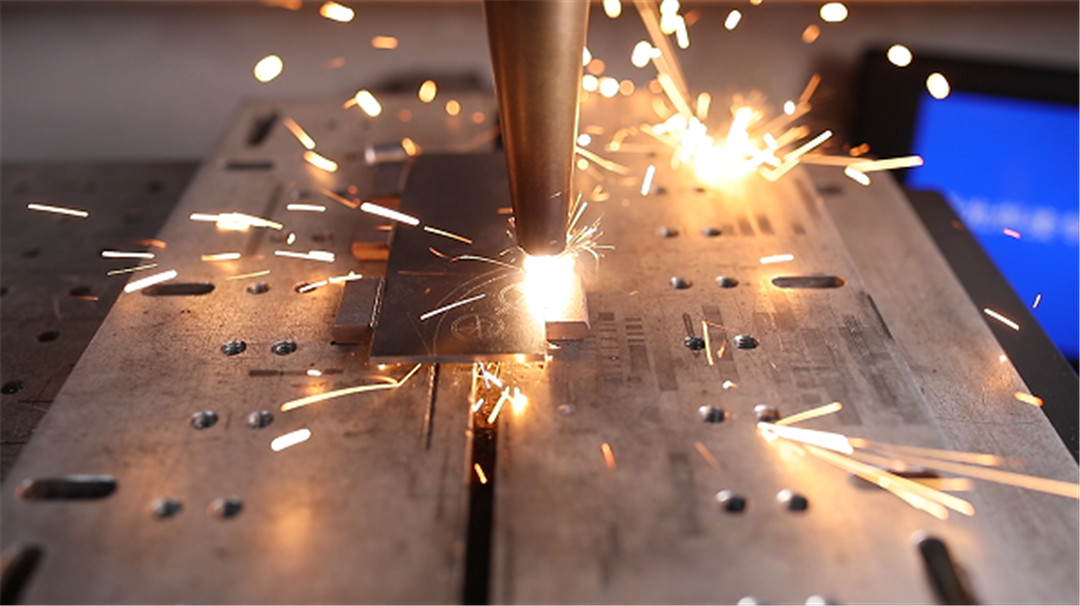

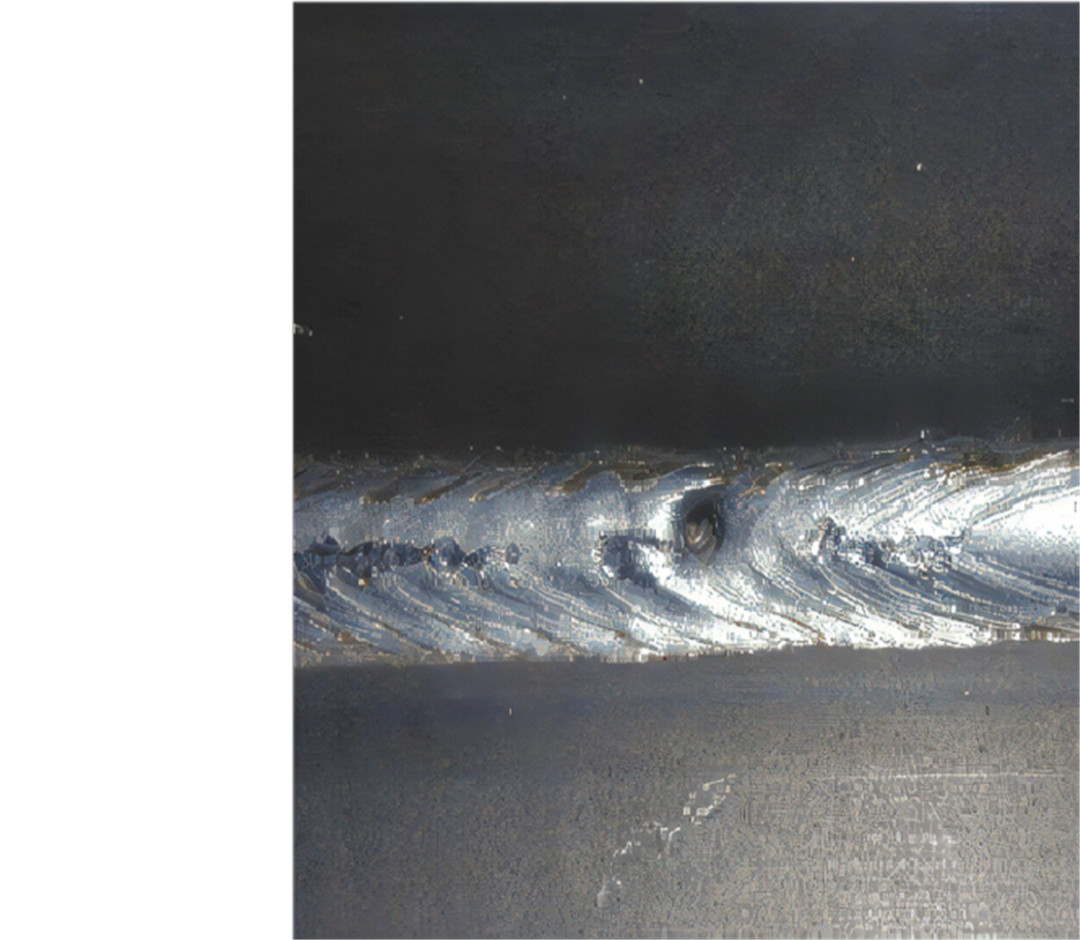

1. Problem: Slag splash

In the process of laser welding, the melted material splashes everywhere and adheres to the surface of the material, making metal particles appear on the surface and affecting the beauty of the product.

The cause of the problem: spatter may be due to excessive power resulting in too fast melting, but also because the material surface is not clean, or the gas is too strong.

Solution: 1, appropriate power adjustment; 2, pay attention to the material surface cleaning; 3, reduce the gas pressure.

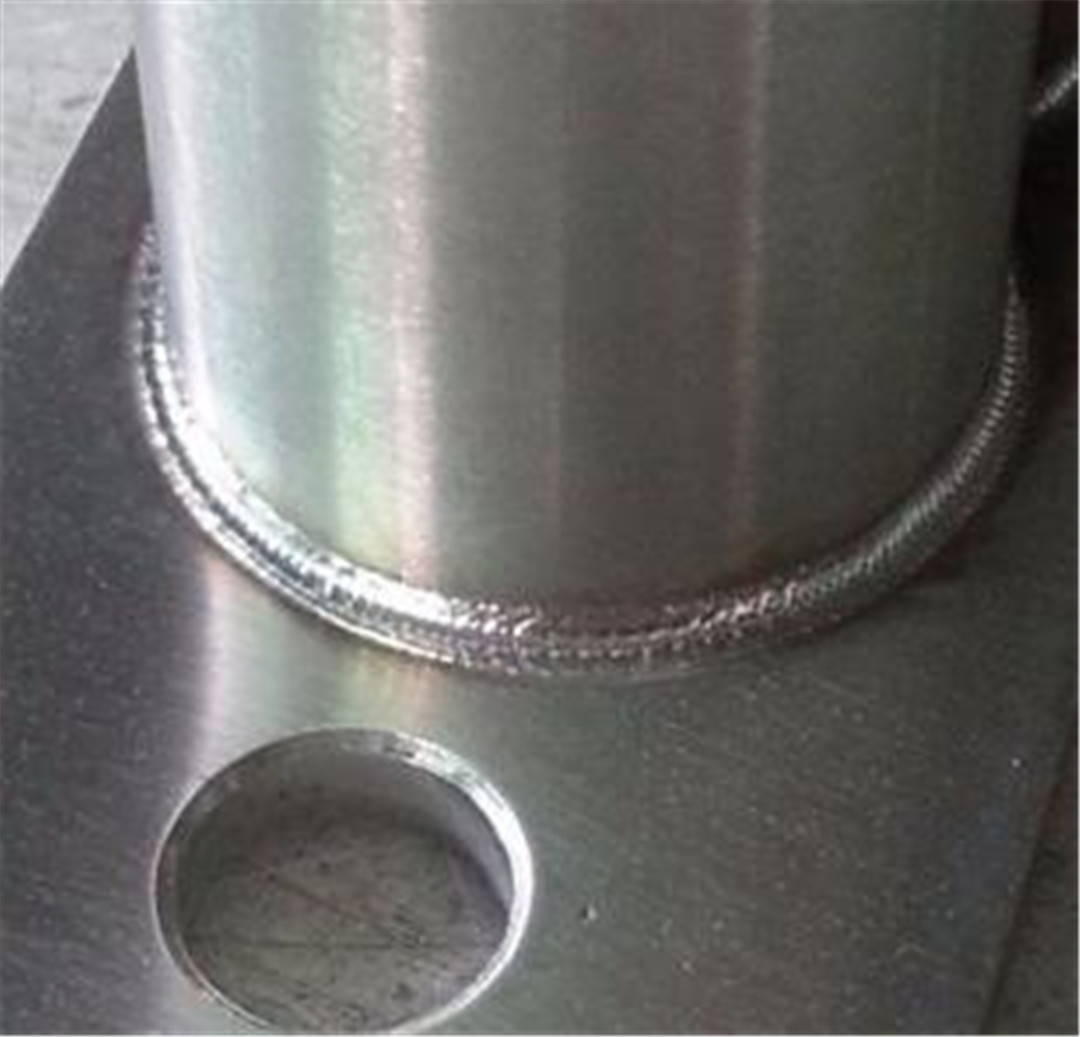

2. Problem: The weld seam is too high

Welding will find that the weld seam is significantly higher than the conventional level, resulting in a fat weld seam, which looks very unattractive.

The reason for the problem: the wire feed speed is too fast, or welding speed is too slow.

Solution: 1. Reduce the wire feed speed in the control system; 2. Increase the welding speed.

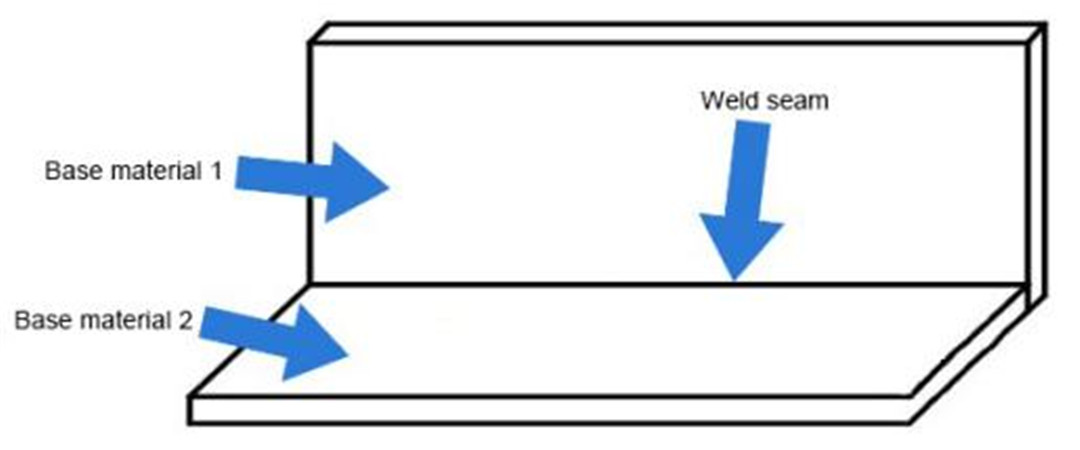

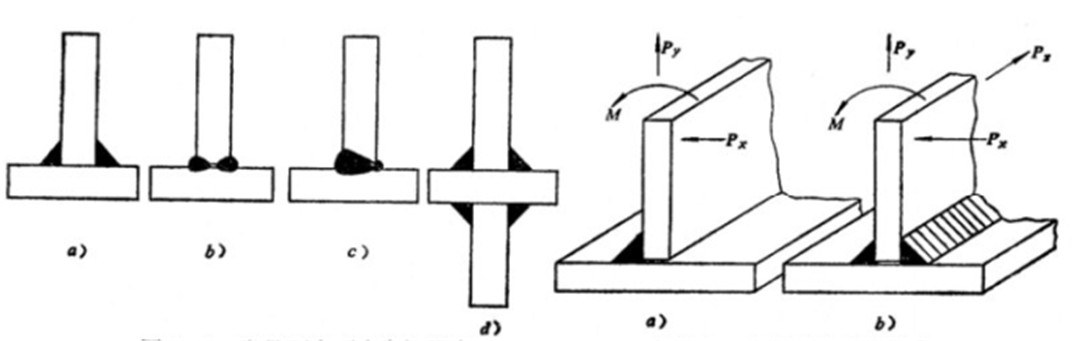

3. Problem: Welding offset

Welding without solidification at the structural joints and inaccurate positioning can lead to complete failure of welding.

Cause of the problem: inaccurate positioning during welding; inconsistent position of wire feed and laser irradiation.

Solution: 1. Adjust the laser offset and swing angle in the board; 2. Check the connection between the wire feeder and the laser head for deviation.

4. Problem: The color of the weld is too dark

When welding stainless steel, aluminum alloy and other materials, the weld color is too dark will make the weld and the material surface produce strong contrast, extremely affect the beauty.

The reason for the problem: the laser power is too small resulting in insufficient combustion, or welding speed is too fast.

Solution: 1. adjust the laser power; 2. adjust the welding speed.

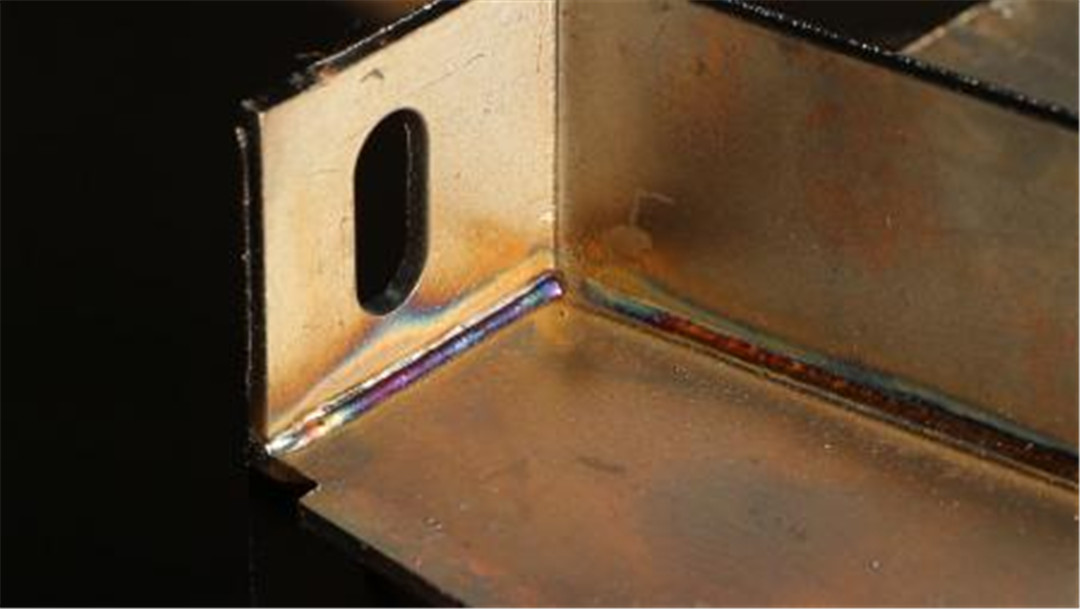

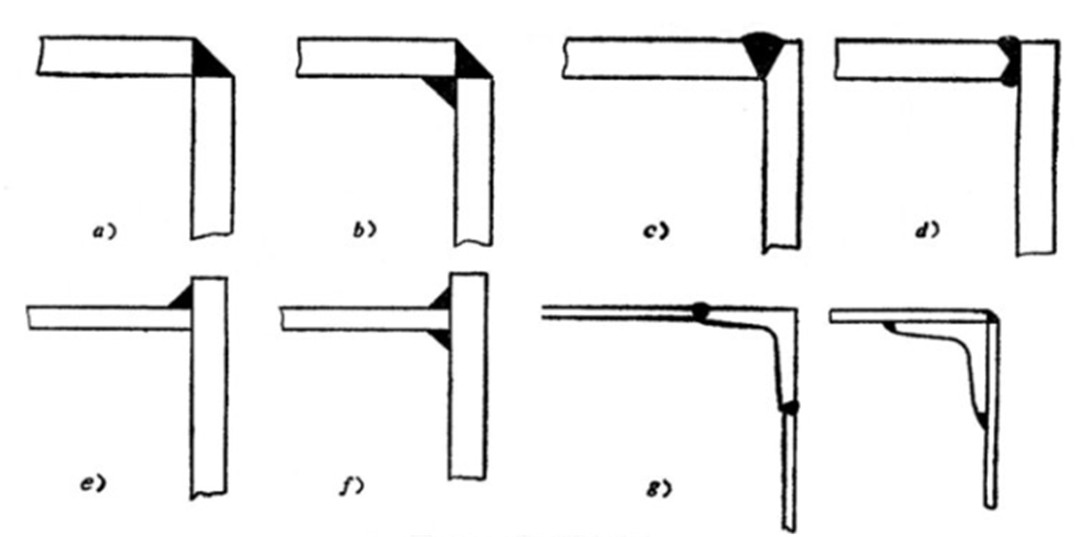

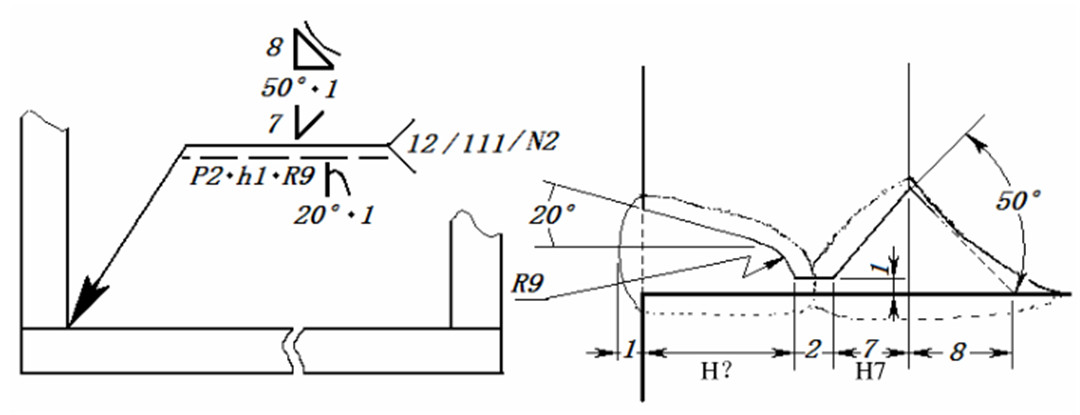

5. Problem: Uneven corner welding molding

When welding the inner and outer corners, the corners are not adjusted to speed or posture, which can easily lead to uneven welding at the corners, affecting both the strength of the weld and the beauty of the weld.

Cause of the problem: inconvenient welding posture.

Solution: Adjust the focus offset in the laser control system so that the handheld laser head can carry out welding operations sideways.

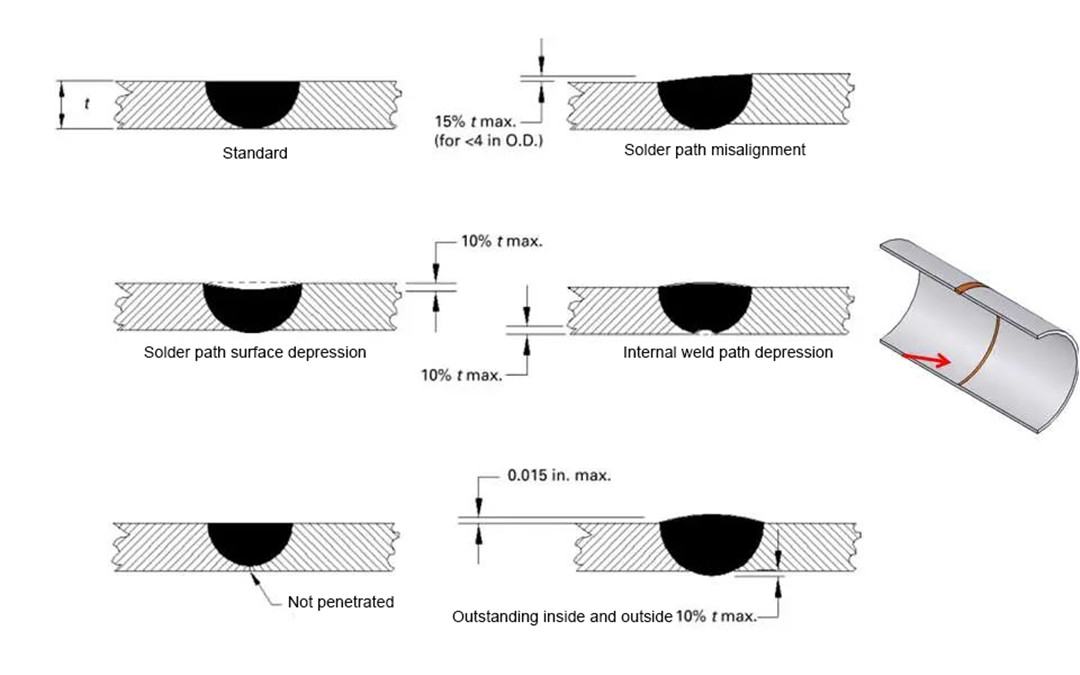

6. Problem: welding seam depression

Dents in the welded joint will lead to insufficient welding strength and unqualified products.

Cause of the problem: The laser power is too large, or the laser focus is set incorrectly, causing the melt pool to be too deep and the material to be over-melted, which in turn leads to the weld seam depression.

Solution: 1. Adjust the laser power; 2. Adjust the laser focus.

7. Problem: the weld thickness is not uniform

Weld seam is sometimes too large, sometimes too small, or sometimes normal.

Cause of the problem: the light or wire feed is not a problem.

Solution: Check the stability of the laser and wire feeder, including power supply voltage, cooling system, control system, grounding wire, etc.

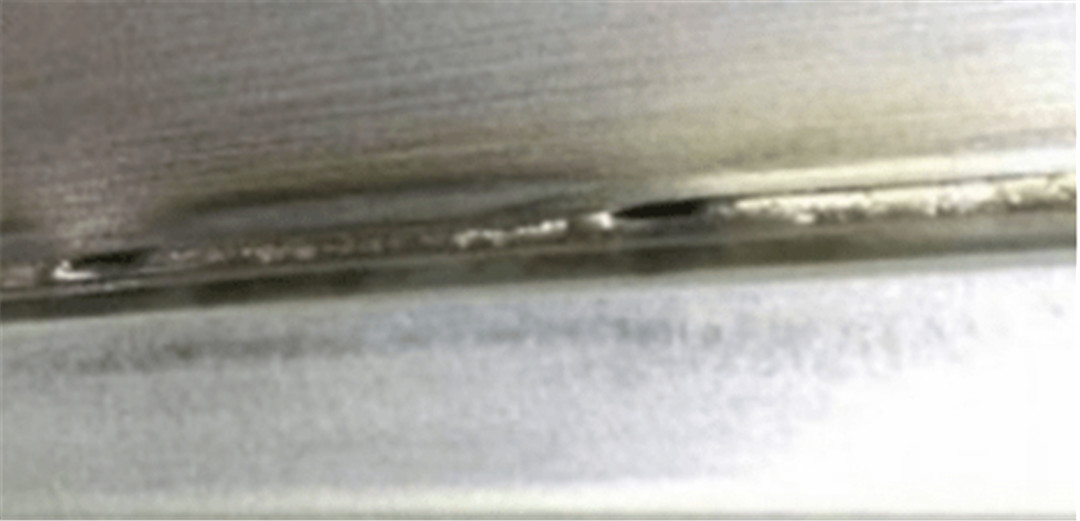

8. Problem: Biting edge

Bite edge refers to the weld and the material is not well combined, beveling and other conditions, thus affecting the quality of welding.

Cause of the problem: welding speed is too fast, resulting in the melt pool is not evenly distributed on both sides of the material, or the material gap is large, the filler material is not enough.

Solution: 1. Adjust the laser power and speed according to the strength of the material and the size of the weld seam; 2. Carry out filling or repair work later.

Maven Laser Automation Co.,Ltd. (Maven laser in short) is a leading manufacturer of laser systems and professional automation solutions, located in Shenzhen, China, founded in 2008. Our professional products are: laser cleaning machine, laser welding machine, robot welding machine and platform welding machine, if you have any professional questions, welcome to consult us.

Post time: Nov-18-2022