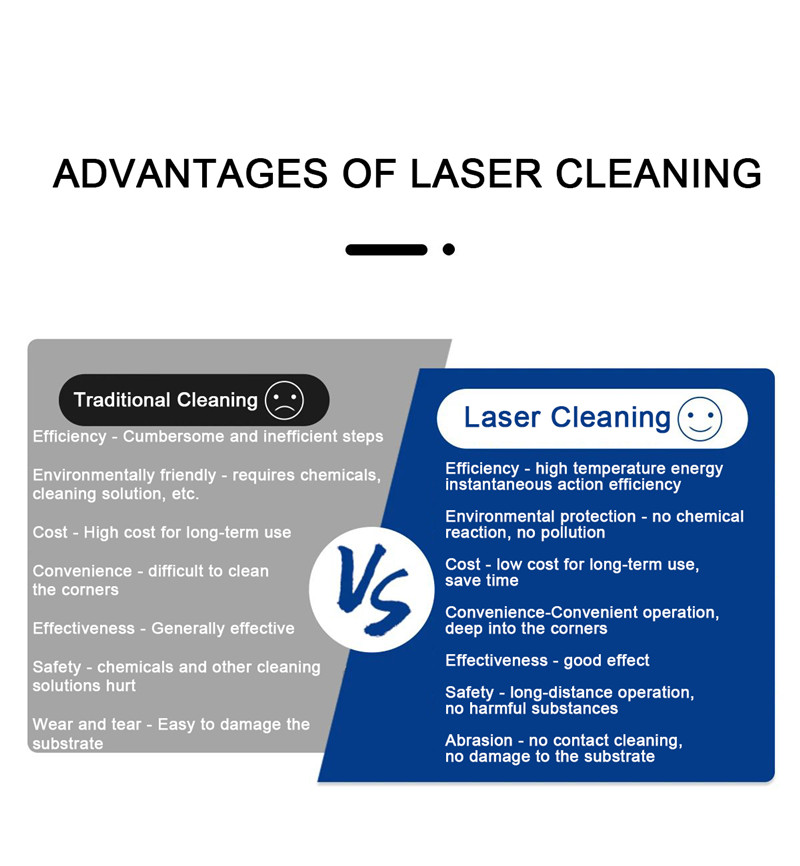

The traditional way of industrial cleaning chemical, dry ice, sandblasting, mechanical grinding, ultrasonic, etc., with the increasing awareness of environmental protection and safety, users of the product cleaning effect and efficiency requirements are higher, laser cleaning more environmentally friendly, more economical and practical advantages are increasingly prominent, sought after by the market.

The principle and characteristics of laser cleaning

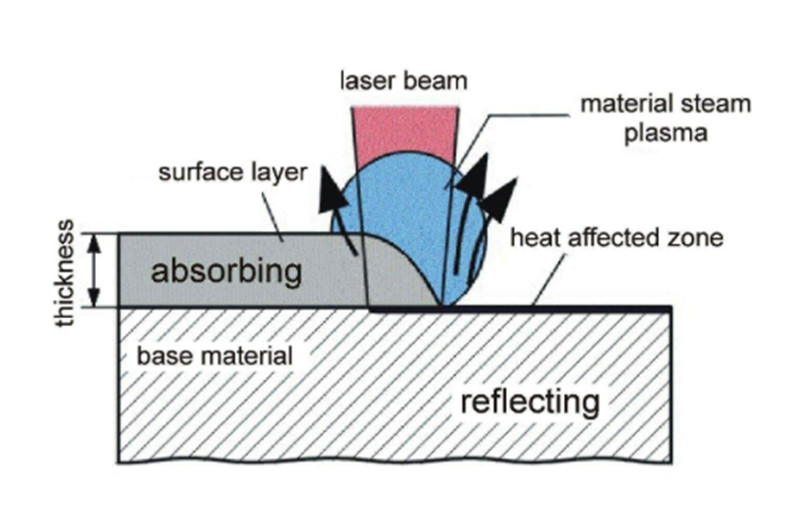

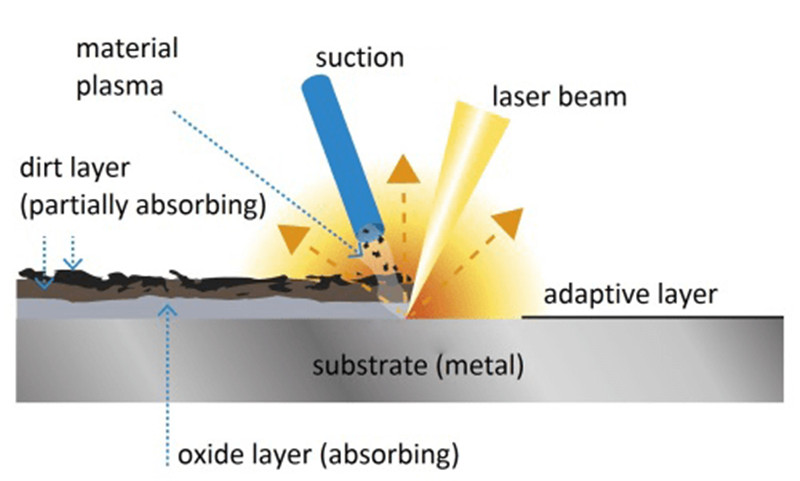

Laser cleaning is the use of high-energy laser beam irradiation of the surface of the workpiece, through the energy conversion generated by the force, so that the surface of the cleaning object dirt, rust, oxides, plating or coating occurs instantaneous melting, ablation, evaporation or stripping, high-speed effective removal of cleaning object surface adhesion or surface coating, so that the contaminants from the material surface, so as to achieve the process of cleaning and do not damage the substrate. It is a new technology based on the effect of laser and material interaction. Completely pollution-free and very environmentally friendly, it is a revolutionary process compared with traditional chemical cleaning.

The core advantages of laser cleaning technology

Compared with the traditional rust removal methods, laser cleaning machine is a new generation of intelligent products. It can do the cleaning of stains without hurting the surface metal, and has the advantages of easy operation, easy integration, high cleanliness and fast cleaning rate.

More advanced: can complete partial rust removal, specified location, size to remove dead ends, a wide range of applications. Using non-contact cleaning work, no damage to the substrate, no pollution, no need for follow-up treatment.

More intelligent: Combined with CNC technology, it can realize automatic target scanning, long time operation and remote control cleaning from a distance, which is easy to realize automatic control.

More efficient: the heat load and mechanical load on the substrate is small, cleaning is non-damaging, lower cost and higher quality. Convenient and light, can move freely, safe and reliable, not to damage the health of the operator.

Modern industrial manufacturing needs the support of professional surface treatment technology, and at this stage of global manufacturing production in the surface treatment demand is growing, and urgently need advanced processes and technologies to achieve alternative and fill, and as a modern advanced surface treatment process of laser cleaning, therefore by more and more industry attention, and become a hot spot of concern in various industrial fields. Laser cleaning is the use of high frequency short pulse laser as a working medium cleaning solutions. Specific wavelength of high-energy beam is absorbed by the rust layer, paint layer, pollution layer, the formation of rapidly expanding plasma (highly ionized unstable gas), while generating shock waves, shock waves make the pollutants into fragments and be removed.

Most importantly, the laser cleaning process without the use of any chemicals and cleaning solutions, cleaning down the waste is basically a solid powder, small size, easy to store, can be adsorbed and recycled, no photochemical reactions, no noise and environmental pollution, while not harming the health of the operator, easy to achieve automated control, automated laser cleaning, which makes laser cleaning technology to become the safest surface cleaning and environmental protection solutions. Laser cleaning products to achieve full power coverage, different power of the laser cleaning machine can be used for different scenarios, to ensure efficiency and cleaning quality at the same time, taking into account the portability, flexibility, environmental protection, powerful. For different application scenarios, Maven laser cleaning solutions cover the mold industry, automotive industry, rail transportation industry, electronics industry, manufacturing industry, medical devices and other metal surface laser cleaning and surface laser pretreatment, to provide customers with a series of complete laser cleaning solutions and related supporting facilities.

Laser cleaning has the advantages of traditional cleaning, from the development of the industry, the popularity of laser cleaning machine is increasing year by year, is the ideal choice for a new generation of industrial cleaning technology. maven laser cleaning machine since the market, well received by the majority of customers, now it has become an industrial cleaning can replace the traditional cleaning of the choice, I believe that in the future with the continuous improvement and upgrading of laser cleaning machine, laser I believe that in the future, with the continuous improvement and upgrading of laser cleaning machine, laser cleaning machine can be applied in the family, to bring real convenience to our life.

1.High efficiency

Under the action of high temperature energy, deposits instantly vaporize and evaporate from the surface of the object, the time required is very short. The traditional cleaning methods, such as ultrasonic cleaning, to be preheated, cooling and other processes before cleaning, the time required is long.

2. More environmentally friendly

Laser cleaning is a "green" cleaning method, do not need to use any chemicals and cleaning solutions, cleaning down the waste is basically a solid powder, small size, easy to store, recyclable, no photochemical reaction, will not produce pollution. Can easily solve the problem of environmental pollution brought about by chemical cleaning. Often an extractor fan can solve the problem of waste generated by cleaning.

3. Low cost

Laser cleaning speed, high efficiency, saving time; purchase laser cleaning system, although the one-time investment is high, but the cleaning system can be long-term stable use, low operating costs, more importantly, you can easily achieve automated operation.

4. More convenient

Laser cleaning can remove various types of contaminants on the surface of various materials, to achieve the cleanliness of conventional cleaning can not be achieved. And also in the case of no damage to the surface of the material can be selectively clean the surface of the material pollutants.

5. Good effect

Traditional cleaning methods are often contact cleaning, cleaning the surface of the object has mechanical force, damage to the surface of the object or cleaning media attached to the surface of the object being cleaned, can not be removed, resulting in secondary pollution. Laser cleaning of non-abrasive and non-contact, non-thermal effect will not damage the substrate, so that these problems are solved.

6. Easy to control

Laser can be transmitted through fiber optic, with robots and robots, easy to achieve long-distance operation, can clean the traditional method is not easy to reach parts. According to the material, you can choose the pulse frequency, energy and wavelength to achieve better results.

7. High safety

Long-distance operation, no harmful substances and gases. The safety of the operator is guaranteed.

8. No wear and tear

The cleaning process is non-contact and does not cause any abrasion to the substrate metal surface.

What are the main scenarios for laser cleaning?

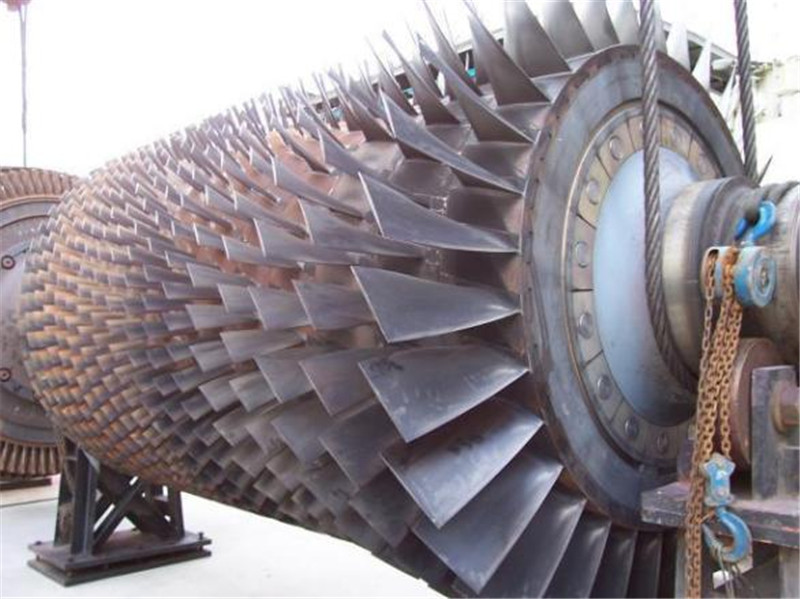

Laser cleaning is currently very widely used in industry, mainly for rust removal, paint removal, oil removal and removal of precision parts oxide film layer, such as ships, auto repair, rubber molds, high-end machine tools, rail, aerospace, construction. The industry such as cultural relics, due to its high efficiency, energy saving and environmental protection, etc., currently in the precision mold, machinery manufacturing, shipbuilding and other industries are very popular.

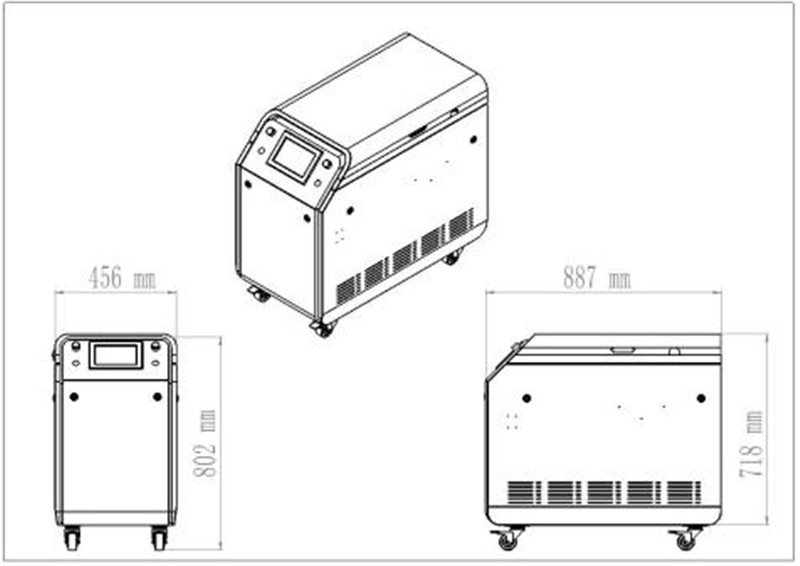

Maven laser automation company focus on laser industry for 14 years, we specialize in laser marking, we have machine cabinet laser cleaning machine, trolley case laser cleaning machine, backpack laser cleaning machine and three in one laser cleaning machine, in addition, we also have laser welding machine, laser cutting machine and laser marking engraving machine, if you are interested in our machine, you can follow us and feel free to contact us.

Post time: Nov-14-2022