As an efficient and environmentally friendly cleaning method, laser cleaning technology is gradually replacing traditional chemical cleaning and mechanical cleaning methods. With the country’s increasingly strict environmental protection requirements and the continuous pursuit of cleaning quality and efficiency in the industrial manufacturing field, the market demand for laser cleaning technology is growing rapidly. As a major manufacturing country, China has a huge industrial base, which provides broad space for the widespread application of laser cleaning technology. In aerospace, rail transit, automobile manufacturing, mold manufacturing and other industries, laser cleaning technology has been widely used and is gradually expanding to other industries.

Workpiece surface cleaning technology is widely used in many fields. Traditional cleaning methods are often contact cleaning, which exerts mechanical force on the surface of the object to be cleaned, damaging the surface of the object or the cleaning medium adheres to the surface of the object to be cleaned and cannot be removed. , causing secondary pollution. Nowadays, the country advocates the development of green and environmentally friendly emerging industries, and laser cleaning is the best choice. The non-abrasive and non-contact nature of laser cleaning solves these problems. Laser cleaning equipment is suitable for cleaning objects of various materials and is considered the most reliable and effective cleaning method.

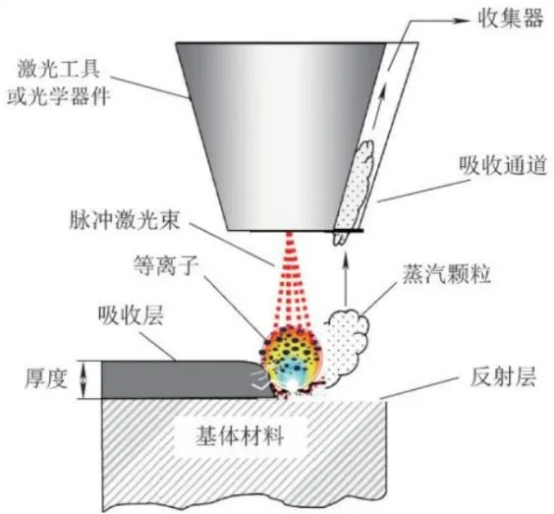

Laser cleaning principle

Laser cleaning is to irradiate a high-energy-density laser beam to the part of the object to be cleaned, so that the laser is absorbed by the contamination layer and the substrate. Through processes such as light stripping and vaporization, the adhesion between the contaminants and the substrate is overcome, so that the The contaminants leave the surface of the object to achieve the purpose of cleaning without damaging the object itself.

Figure 1: Schematic diagram of laser cleaning.

In the field of laser cleaning, fiber lasers have become the winner among laser cleaning light sources due to their ultra-high photoelectric conversion efficiency, excellent beam quality, stable performance and sustainable development. Fiber lasers are represented by two types: pulsed fiber lasers and continuous fiber lasers, which occupy the market leading positions in macro material processing and precision material processing respectively.

Figure 2: Pulsed fiber laser construction.

Pulsed Fiber Laser vs. Continuous Fiber Laser Cleaning Application Comparison

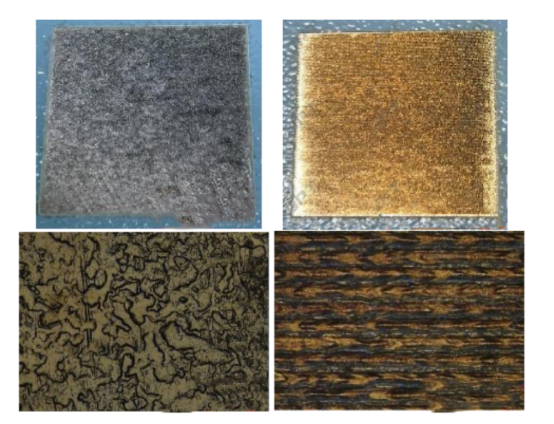

For emerging laser cleaning applications, many people may be a little confused when faced with pulse lasers and continuous lasers on the market: Should they choose pulse fiber lasers or continuous fiber lasers? Below, two different types of lasers are used to conduct paint removal experiments on the surfaces of two materials, and the optimal laser cleaning parameters and optimized cleaning effects are used for comparison.

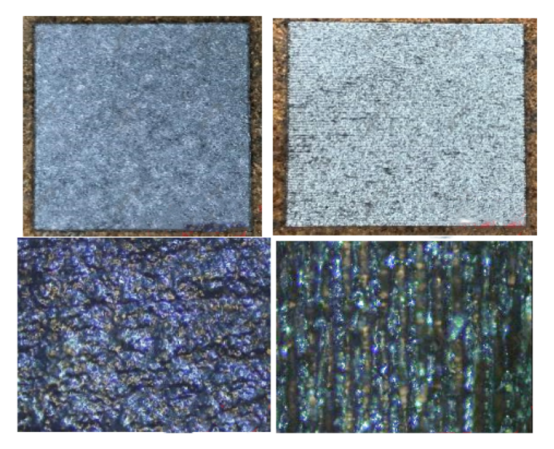

Through microscopic observation, sheet metal has remelted after being processed by high-power continuous fiber laser. After the steel is processed by the MOPA pulse fiber laser, the base material is slightly damaged and the texture of the base material is maintained; after the steel is processed by the continuous fiber laser, serious damage and molten material are produced.

MOPA pulsed fiber laser (left) CW fiber laser (right)

Pulsed fiber laser (left) Continuous fiber laser (right)

From the above comparison, it can be seen that continuous fiber lasers can easily cause discoloration and deformation of the substrate due to their large heat input. If the requirements for substrate damage are not high and the thickness of the material to be cleaned is thin, this type of laser can be used as the light source. Pulsed fiber laser relies on high peak energy and high repetition frequency pulses to act on materials, and instantly vaporizes and oscillates the cleaning materials to peel them off; it has small thermal effects, high compatibility, and high precision, and can achieve various tasks. Destroy the characteristics of the substrate.

From this conclusion, in the face of high precision, it is necessary to strictly control the temperature rise of the substrate, and in application scenarios that require the substrate to be non-destructive, such as painted aluminum and mold steel, it is recommended to choose pulse fiber laser; for some large-scale high-strength aluminum alloy materials, round shaped pipes, etc. Due to their large size and fast heat dissipation, and low requirements on substrate damage, continuous fiber lasers can be selected.

In laser cleaning, material conditions need to be comprehensively considered to ensure that cleaning needs are met while minimizing damage to the substrate. According to the actual working conditions, it is crucial to choose the appropriate laser light source.

If laser cleaning wants to enter large-scale application, it is inseparable from the innovation of new technologies and new processes. Maven will continue to adhere to the positioning of laser +, control the pace of development steadily, strive to deepen the upstream core laser light source technology, and focus on solving key laser materials and Key issues of components provide a source of power for advanced manufacturing.

Post time: May-07-2024