1. Laser industry overview

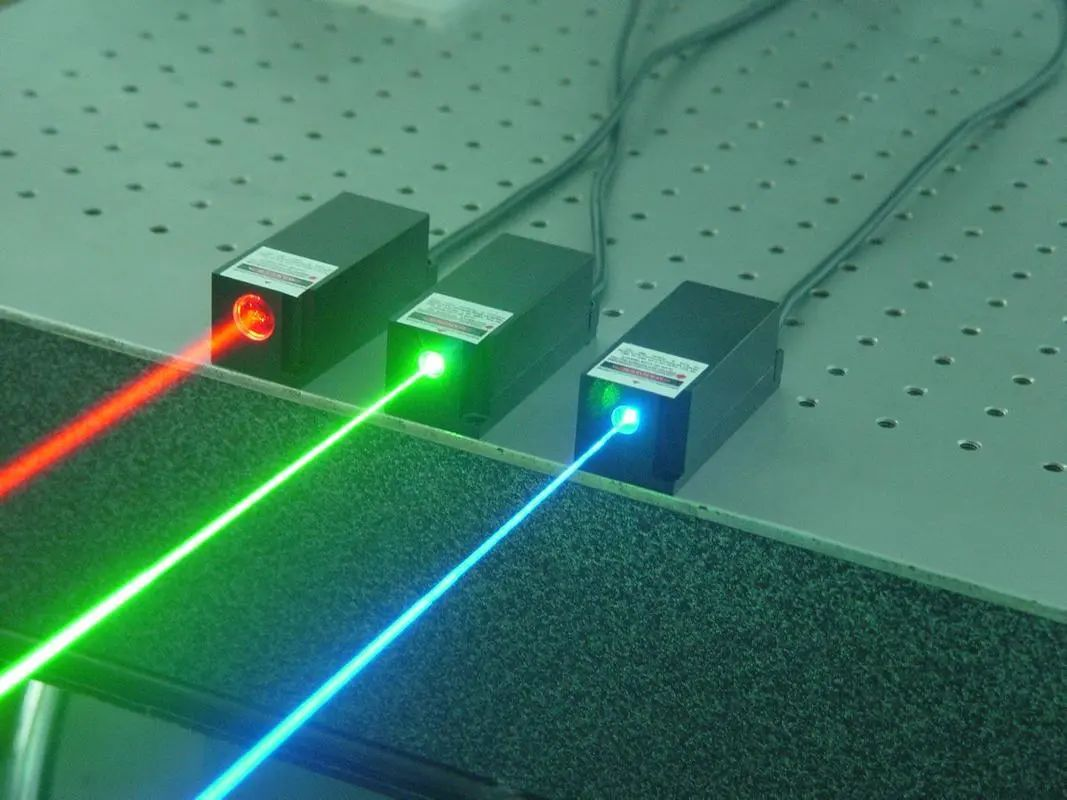

(1) Laser Introduction

Laser (Light Amplification by Stimulated Emission of Radiation, abbreviated as LASER) is a collimated, monochromatic, coherent, directional beam of light produced by the amplification of light radiation at a narrow frequency through excited feedback resonance and radiation.

Laser technology originated in the early 1960s, and because of its completely different nature from ordinary light, laser was soon widely used in various fields and profoundly influenced the development and transformation of science, technology, economy and society.

The birth of the laser has dramatically changed the face of ancient optics, expanding classical optical physics into a new high-tech discipline that encompasses both classical optics and modern photonics, making an irreplaceable contribution to the development of human economy and society. Laser physics research has contributed to the flourishing of two major branches of modern photonic physics: energy photonics and information photonics. It covers nonlinear optics, quantum optics, quantum computing, laser sensing and communication, laser plasma physics, laser chemistry, laser biology, laser medicine, ultra-precise laser spectroscopy and metrology, laser atomic physics including laser cooling and Bose-Einstein condensed matter research, laser functional materials, laser manufacturing, laser micro-optoelectronic chip fabrication, laser 3D printing and more than 20 international frontier disciplines and technological applications. The Department of Laser Science and Technology (DSL) has been established in the following areas.

In the laser manufacturing industry, the world has entered the era of "light manufacturing", according to the international laser industry statistics, 50% of the annual GDP of the United States1 is related to the rapid market expansion of high-level laser applications. Several developed countries, represented by the United States, Germany and Japan, have basically completed the replacement of traditional processes with laser processing in major manufacturing industries such as automotive and aviation. Laser in industrial manufacturing has shown great potential for low-cost, high-quality, high-efficiency and special manufacturing applications that cannot be achieved by conventional manufacturing, and has become an important driver of competition and innovation among the world's major industrial countries. Countries are actively supporting laser technology as one of their most important cutting-edge technologies and have developed national laser industry development plans.

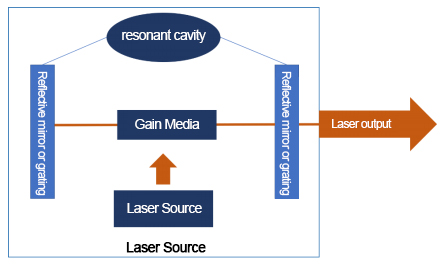

(2) Laser Source Principle

The laser is a device that uses excited radiation to produce visible or invisible light, with complex structure and high technical barriers. The optical system is mainly composed of pump source (excitation source), gain medium (working substance) and resonant cavity and other optical device materials. The gain medium is the source of photon generation, and by absorbing the energy generated by the pump source, the gain medium jumps from the ground state to the excited state. Since the excited state is unstable, at this time, the gain medium will release energy to return to the steady state of the ground state. In this process of energy release, the gain medium produces photons, and these photons have a high degree of consistency in energy, wavelength and direction, they are constantly reflected in the optical resonant cavity, reciprocal movement, so as to continuously amplify, and finally shoot out the laser through the reflector to form a laser beam. As the core optical system of the terminal equipment, the performance of the laser often directly determines the quality and power of the output beam of the laser equipment, is the core component of the terminal laser equipment.

The pump source (excitation source) provides energy excitation to the gain medium. The gain medium is excited to produce photons to generate and amplify the laser. The resonant cavity is the place where the photon characteristics (frequency, phase and direction of operation) are regulated to obtain a high quality output light source by controlling the photon oscillations in the cavity. The pump source (excitation source) provides the energy excitation for the gain medium. The gain medium is excited to produce photons to generate and amplify the laser. The resonant cavity is the place where the photon characteristics (frequency, phase and direction of operation) are adjusted to obtain a high quality output light source by controlling the photon oscillations in the cavity.

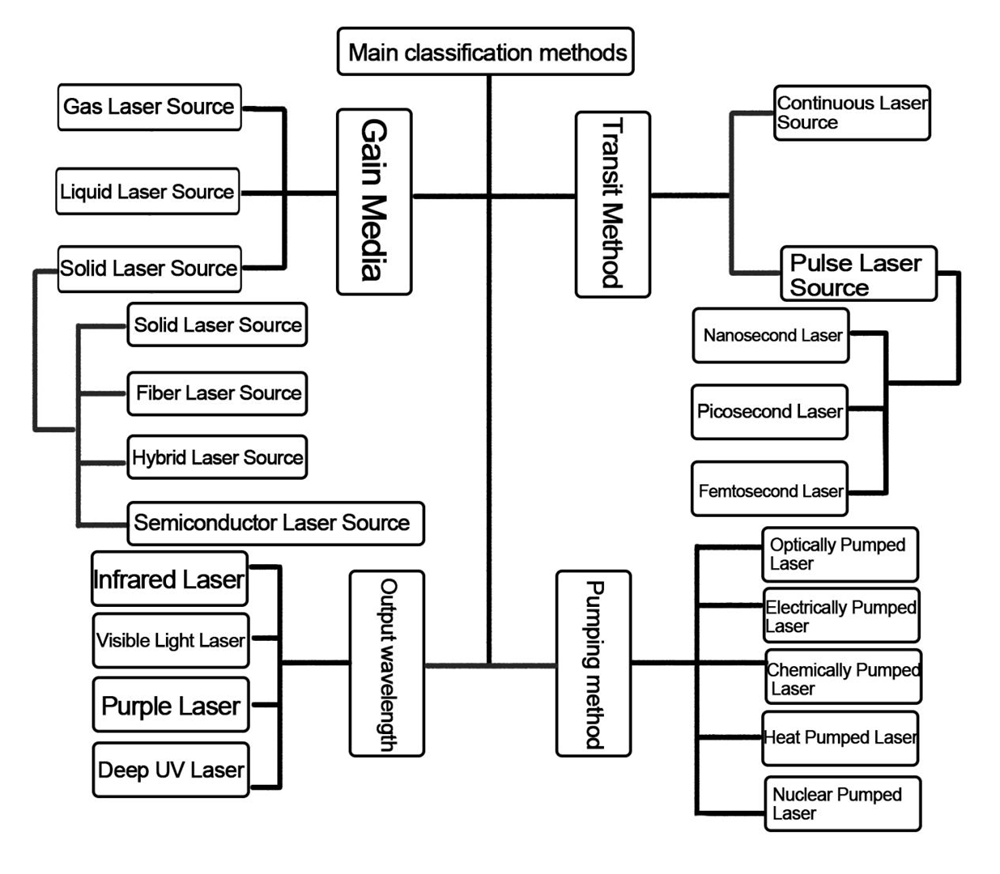

(3) Classification of Laser Source

Laser source can be classified according to gain medium, output wavelength, operation mode, and pumping mode, as follows

① Classification by gain medium

According to the different gain media, lasers can be divided into solid state (including solid, semiconductor, fiber, hybrid), liquid lasers, gas lasers, etc.

| Laser Source Type | Gain Media | Main Features |

| Solid State Laser Source | Solids, Semiconductors, Fiber Optics, Hybrid | Nice stability, high power, low maintenance cost, suitable for industrialization |

| Liquid Laser Source | Chemical liquids | Optional wavelength range hit, but large size and high maintenance cost |

| Gas Laser Source | Gases | High quality laser light source, but larger size and higher maintenance costs |

| Free Electron Laser Source | Electron beam in a specific magnetic field | Ultra-high power and high quality laser output can be achieved, but manufacturing technology and production costs are very high |

Due to the good stability, high power and low maintenance cost, the application of solid-state lasers takes absolute advantage.

Among solid-state lasers, semiconductor lasers have the advantages of high efficiency, small size, long life, low energy consumption, etc. On the one hand, they can be directly applied as the core light source and support for laser processing, medical, communication, sensing, display, monitoring and defense applications, and have become an important basis for the development of modern laser technology with strategic development significance.

On the other hand, semiconductor lasers can also be used as the core pumping light source for other lasers such as solid-state lasers and fiber lasers, greatly promoting the technological progress of the entire laser field. All major developed countries in the world have included it in their national development plans, giving strong support and getting rapid development.

② According to the pumping method

Lasers can be divided into electrically pumped, optically pumped, chemically pumped lasers, etc. according to the pumping method.

Electrically pumped lasers refer to lasers excited by current, gas lasers are mostly excited by gas discharge, while semiconductor lasers are mostly excited by current injection.

Almost all solid state lasers and liquid lasers are optical pump lasers, and semiconductor lasers are used as the core pumping source for optical pump lasers.

Chemically pumped lasers refer to lasers that use the energy released from chemical reactions to excite the working material.

③Classification by operation mode

Lasers can be divided into continuous lasers and pulsed lasers according to their mode of operation.

Continuous lasers have a stable distribution of the number of particles at each energy level and the radiation field in the cavity, and their operation is characterized by the excitation of the working material and the corresponding laser output in a continuous manner over a long period of time. Continuous lasers can output laser light continuously for a longer period of time, but the thermal effect is more obvious.

Pulsed lasers refer to the time duration when the laser power is maintained at a certain value, and output laser light in a discontinuous manner, with the main characteristics of small thermal effect and good controllability.

④ Classification by output wavelength

Lasers can be classified according to wavelength as infrared lasers, visible lasers, ultraviolet lasers, deep ultraviolet lasers, and so on. The wavelength range of light that can be absorbed by different structured materials is different, so lasers of different wavelengths are needed for fine processing of different materials or for different application scenarios. Infrared lasers and UV lasers are the two most widely used lasers. Infrared lasers are mainly used in "thermal processing", where the material on the surface of the material is heated and vaporized (evaporated) to remove the material; in thin film non-metallic material processing, semiconductor wafer cutting, organic glass cutting, drilling, marking and other fields, high energy In the field of thin film non-metallic material processing, semiconductor wafer cutting, organic glass cutting, drilling, marking, etc., the high energy UV photons directly break the molecular bonds on the surface of non-metallic materials, so that the molecules can be separated from the object, and this method does not produce high heat reaction, so it is usually called "cold processing".

Because of the high energy of UV photons, it is difficult to generate a certain high power continuous UV laser by external excitation source, so the UV laser is generally generated by the application of crystal material nonlinear effect frequency conversion method, so the current widely used industrial field of UV lasers are mainly solid-state UV lasers.

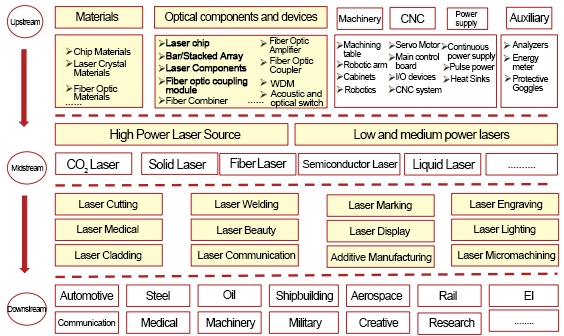

(4) Industry chain

The upstream of the industry chain is the use of semiconductor raw materials, high-end equipment and related production accessories to manufacture laser cores and optoelectronic devices, which is the cornerstone of the laser industry and has a high access threshold. The midstream of the industry chain is the use of upstream laser chips and optoelectronic devices, modules, optical components, etc. as pump sources for the manufacture and sale of various lasers, including direct semiconductor lasers, carbon dioxide lasers, solid-state lasers, fiber lasers, etc.; the downstream industry mainly refers to the application areas of various lasers, including industrial processing equipment, LIDAR, optical communications, medical beauty and other application industries

①Upstream suppliers

The raw materials for upstream products such as semiconductor laser chips, devices and modules are mainly various chip materials, fiber materials and machined parts, including substrates, heat sinks, chemicals and housing sets. The chip processing requires high quality and performance of upstream raw materials, mainly from foreign suppliers, but the degree of localization is gradually increasing, and gradually achieve independent control. The performance of the main upstream raw materials has a direct impact on the quality of semiconductor laser chips, with the continuous improvement of the performance of various chip materials, to improve the performance of the industry's products play a positive role in promoting.

②Midstream industry chain

Semiconductor laser chip is the core pump light source of various types of lasers in the midstream of the industry chain, and plays a positive role in promoting the development of midstream lasers. In the field of midstream lasers, the United States, Germany and other overseas enterprises dominate, but after the rapid development of the domestic laser industry in recent years, the midstream market of the industry chain has achieved rapid domestic substitution.

③Industrial chain downstream

The downstream industry has a greater role in promoting the development of the industry, so the development of the downstream industry will directly affect the market space of the industry. The continuous growth of China's economy and the emergence of strategic opportunities for economic transformation have created better development conditions for the development of this industry. China is moving from a manufacturing country to a manufacturing powerhouse, and downstream lasers and laser equipment are one of the keys to upgrading the manufacturing industry, which provides a good demand environment for the long-term improvement of this industry. The downstream industry's requirements for the performance index of semiconductor laser chips and their devices are increasing, and domestic enterprises are gradually entering the high power laser market from the low power laser market, so the industry must continuously increase the investment in the field of technology research and development and independent innovation.

2. semiconductor laser industry development status

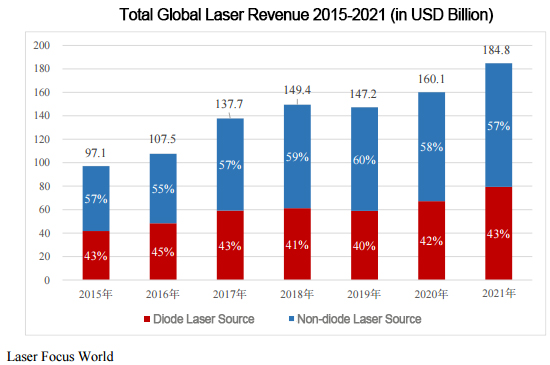

Semiconductor lasers have the best energy conversion efficiency among all kinds of lasers, on the one hand, they can be used as the core pump source of optical fiber lasers, solid-state lasers and other optical pump lasers. On the other hand, with the continuous breakthrough of semiconductor laser technology in terms of power efficiency, brightness, lifetime, multi-wavelength, modulation rate, etc., semiconductor lasers are widely used in material processing, medical, optical communication, optical sensing, defense, etc. According to Laser Focus World, the total global revenue of diode lasers, i.e., semiconductor lasers and non-diode lasers, is estimated to be $18,480 million in 2021, with semiconductor lasers accounting for 43% of the total revenue.

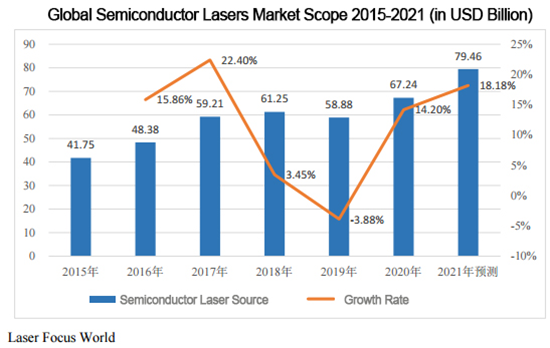

According to Laser Focus World, the global semiconductor laser market will be $6,724 million in 2020, up 14.20% from the previous year. With the development of global intelligence, the growing demand for lasers in smart devices, consumer electronics, new energy and other fields, as well as the continued expansion of medical, beauty equipment and other emerging applications, semiconductor lasers can be used as a pump source for optical pump lasers, and its market size will continue to maintain stable growth. 2021 global semiconductor laser market size of $7.946 billion, the market growth rate of 18.18%.

Through the joint efforts of technical experts and enterprises and practitioners, China's semiconductor laser industry has achieved extraordinary development, so that China's semiconductor laser industry has experienced the process from scratch, and the beginning of the prototype of China's semiconductor laser industry. In recent years, China has increased the development of the laser industry, and various regions have been devoted to scientific research, technology enhancement, market development and the construction of laser industrial parks under the leadership of the government and the cooperation of laser enterprises.

3. Future development trend of China's laser industry

Compared with developed countries in Europe and the United States, China's laser technology is not late, but in the application of laser technology and high-end core technology there is still a considerable gap, especially the upstream semiconductor laser chip and other core components are still dependent on imports.

The developed countries represented by the United States, Germany and Japan have basically completed the replacement of traditional manufacturing technology in some large industrial fields and entered the era of "light manufacturing"; although the development of laser applications in China is rapid, but the application penetration rate is still relatively low. As the core technology of industrial upgrading, the laser industry will continue to be a key area of national support, and continue to expand the scope of application, and ultimately promote China's manufacturing industry to the "light manufacturing" era. From the current development situation, the development of China's laser industry shows the following development trends.

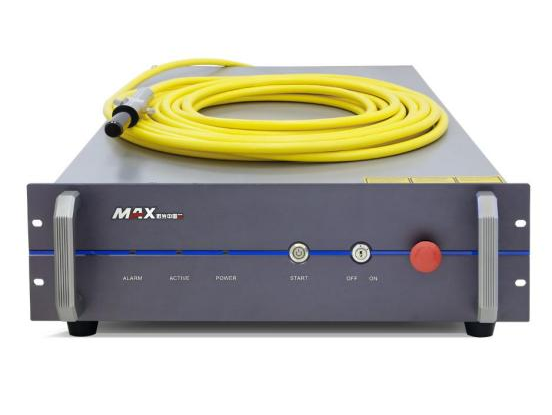

(1) Semiconductor laser chip and other core components gradually realize localization

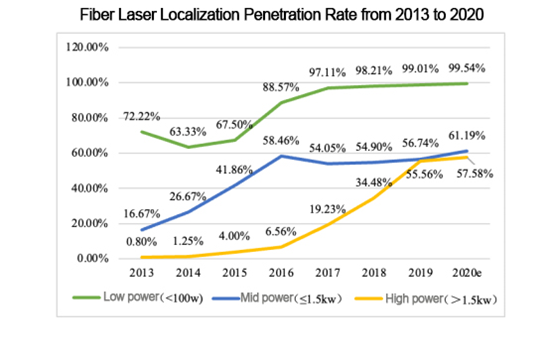

Take fiber laser as an example, high power fiber laser pump source is the main application area of semiconductor laser, high power semiconductor laser chip and module is an important component of fiber laser. In recent years, China's optical fiber laser industry is in a rapid growth stage, and the degree of localization is increasing year by year.

In terms of market penetration, in the low-power fiber laser market, the market share of domestic lasers reached 99.01% in 2019; in the medium-power fiber laser market, the penetration rate of domestic lasers has been maintained at more than 50% in recent years; the localization process of high-power fiber lasers is also gradually advancing, from 2013 to 2019 to achieve "from scratch". The localization process of high-power fiber lasers is also gradually advancing, from 2013 to 2019, and has reached a penetration rate of 55.56%, and the domestic penetration rate of high-power fiber lasers is expected to be 57.58% in 2020.

However, core components such as high-power semiconductor laser chips are still dependent on imports, and the upstream components of lasers with semiconductor laser chips as the core are gradually being localized, which on the one hand improves the market scale of the upstream components of domestic lasers, and on the other hand, with the localization of the upstream core components, it can improve the ability of domestic laser manufacturers to participate in international competition.

(2) Laser applications penetrate faster and wider

With the gradual localization of upstream core optoelectronic components and the gradual decrease of laser application costs, lasers will penetrate more deeply into many industries.

On the one hand, for China, laser processing also fits into the top ten application areas of China's manufacturing industry, and it is expected that the application areas of laser processing will be further expanded and the market scale will be further expanded in the future. On the other hand, with the continuous popularization and development of technologies such as driverless, advanced assisted driving system, service-oriented robot, 3D sensing, etc., it will be more applied in many fields such as automobile, artificial intelligence, consumer electronics, face recognition, optical communication and national defense research. As the core device or component of the above laser applications, the semiconductor laser will also gain rapid development space.

(3) Higher power, better beam quality, shorter wavelength and faster frequency direction development

In the field of industrial lasers, fiber lasers have made great progress in terms of output power, beam quality and brightness since their introduction. However, higher power can improve processing speed, optimize processing quality, and expand the processing field to heavy industry manufacturing, in automotive manufacturing, aerospace manufacturing, energy, machinery manufacturing, metallurgy, rail transportation construction, scientific research and other fields of application in cutting, welding, surface treatment, etc., fiber laser power requirements continue to increase. The corresponding device manufacturers need to continuously improve the performance of core devices (such as high-power semiconductor laser chip and gain fiber), fiber laser power increase also requires advanced laser modulation technology such as beam combining and power synthesis, which will bring new requirements and challenges to high-power semiconductor laser chip manufacturers. In addition, shorter wavelengths, more wavelengths, faster (ultrafast) laser development is also an important direction, mainly used in integrated circuit chips, displays, consumer electronics, aerospace and other precision microprocessing, as well as life sciences, medical, sensing and other fields, the semiconductor laser chip also put forward new requirements.

(4) for high power laser optoelectronic components demand for further growth

The development and industrialization of high-power fiber laser is the result of the synergistic progress of the industry chain, which requires the support of core optoelectronic components such as pump source, isolator, beam concentrator, etc. The optoelectronic components used in high-power fiber laser are the basis and key components of its development and production, and the expanding market of high-power fiber laser also drives the market demand for core components such as high-power semiconductor laser chips. At the same time, with the continuous improvement of domestic fiber laser technology, import substitution has become an inevitable trend, the laser market share in the world will continue to improve, which also brings great opportunities for local strength of optoelectronic components manufacturers.

Post time: Mar-07-2023