With the continuous development of science and technology and the expansion of various application fields, laser processing technology is gradually penetrating into all walks of life and becoming an important processing tool. In the application of lasers, kilowatt-level MOPA (Master Oscillator Power-Amplifier) lasers are widely used in fields such as material processing and scientific research experiments due to their high peak power, strong penetration, and low thermal impact. They are an important tool to help enterprises improve quality and increase productivity. The ideal tool for efficiency. But precisely because of its high power, in order to maximize the processing efficiency of the kilowatt-level MOPA laser, the selection of accessories is crucial. Only by selecting appropriate laser accessories can we ensure that the laser can work stably and efficiently and better meet various application needs.

High power stability

Mass production of kilowatt-level MOPA with high performance and technical indicators

The ability to stably mass-produce kilowatt-level single-mode MOPA lasers is an important indicator of a company’s MOPA laser R&D, production and manufacturing capabilities. MAVEN currently has multiple versions of high-power MOPA fiber laser cleaning machines that can meet the processing needs of various applications in multiple dimensions.

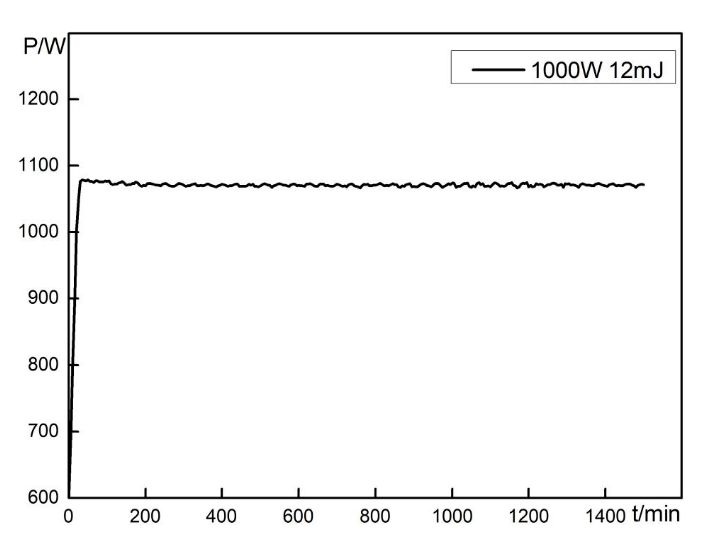

The 24h full power output fluctuation is less than <3%

Beam quality controllable

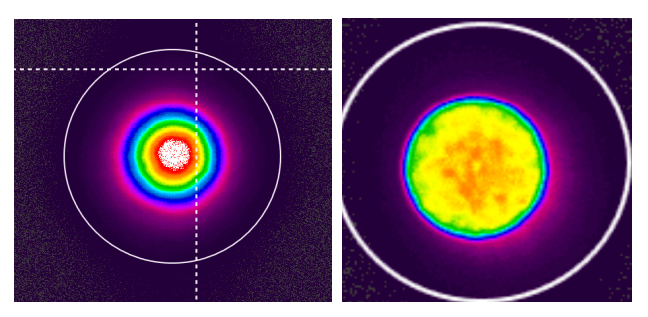

Single-mode Gaussian beam Multi-mode flat-top beam

End-pump signal coupling technology, more refined and reasonable energy level distribution, unique production coiling process, and single-mode high-power collimated isolator with excellent heat-transparent crystal, while output power reaches 1000W, it can also ensure excellent Beam quality.

In the field of fiber laser processing, especially the processing of high-power MOPA nanosecond pulse fiber laser, due to its high peak power, large pulse energy and high frequency, the selection of accessories is particularly important. The main accessories that affect the processing effect of high-power pulse laser include Scanning galvanometer, focusing field mirror and reflector.

How to choose a scanning galvanometer?

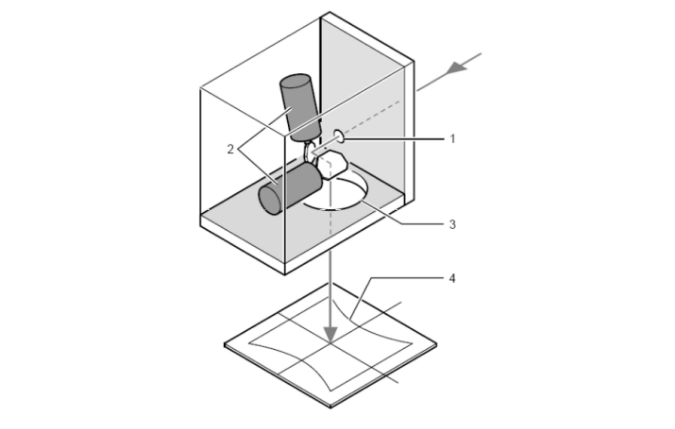

The goal of galvanometer scanning technology is to complete high-speed, high-precision scanning tasks. There are two main determining factors. One is a control system that can achieve high speed and high precision, and the other is a galvanometer with a faster response speed. scanner. The structure of the galvanometer mainly consists of three parts: reflector, motor and drive card, among which the lens is crucial to the stability of processing.

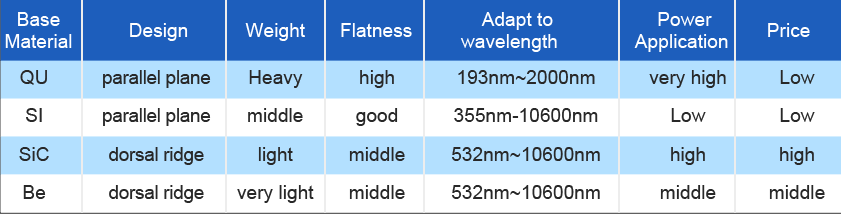

Galvanometer lens material and influencing indicators

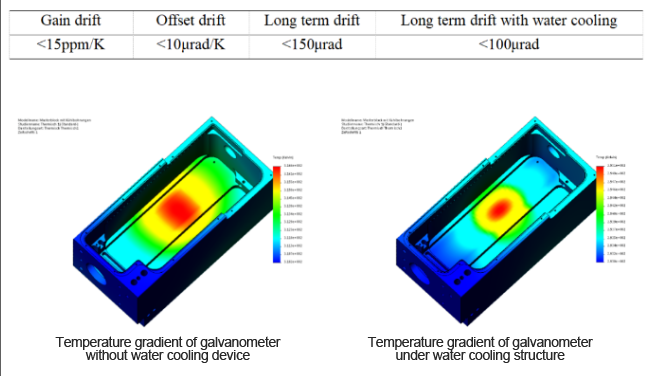

The thermal management system of the scanning galvanometer is also an important factor in ensuring long-term processing stability. Temperature differences will cause the galvanometer to drift and reduce positioning accuracy. Typical values are as follows. Through water-cooling active heat dissipation, long-term processing stability can be improved by 30%.

Typical temperature drift value of galvanometer

The water cooling device can effectively take away heat and ensure long-term stable operation of the galvanometer. The main technical means are to obtain a low turbulence cooling water field through the optimized design of the cooling water channel, and to design an efficient external heat exchange device structure.

In the kilowatt-level high-power MOPA pulse laser system, we strongly recommend the use of high-quality quartz lenses and galvanometer systems with water cooling systems.

How to choose a focusing field lens?

The field lens focuses the collimated laser beam on a point, increases the energy density of the laser beam, and uses the high energy of the laser to perform various material processing such as cutting, marking, welding, cleaning and surface treatment.

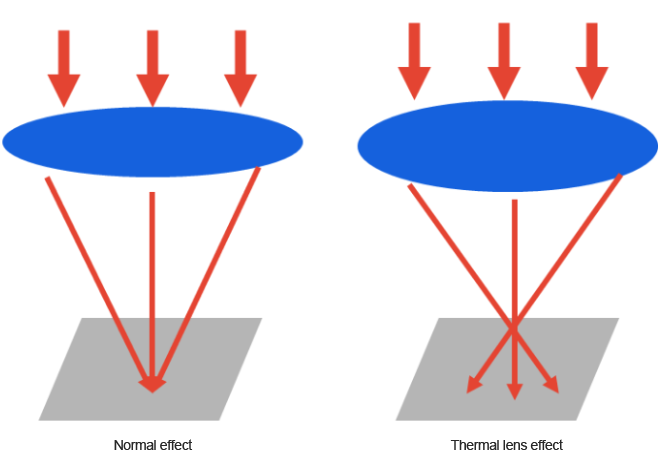

The main factors affecting the processing quality and effect of the field lens are the material of the field lens and the height of the adapter ring. The main materials of the field lens are glass and quartz. The difference between the two lies in the thermal lens effect on high power. After the focusing field lens is continuously irradiated by the laser beam for a long time, it will produce thermal deformation due to the increase in temperature, which will cause transmission optics. The refractive index of the element and the reflection direction of the reflective optical element change, and the thermal lens effect will affect the mode of the laser and the focus position after focusing, which will seriously affect the processing effect. Quartz has a low thermal expansion coefficient and high transmittance, making it a better material choice for high-power field lenses. If necessary, a water-cooling module must be added.

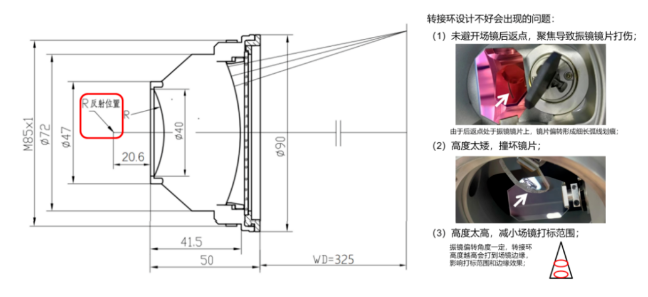

The adapter ring for matching the field lens to the galvanometer is also an important factor that affects the equipment and processing. The appropriate height of the adapter ring can avoid the return point of the field lens and ensure the processing format. If it is too high or too low, it will cause corresponding problems.

In kilowatt-level high-power MOPA pulse laser systems, we strongly recommend the use of high-quality quartz field mirrors with water-cooling modules and a dedicated field mirror adapter ring of appropriate height.

How to match reflective lenses?

The main function of reflective lenses in the optical path structure is to change the direction of the optical path. Choosing good quality reflective lenses and standardized installation methods can play a greater role in some special applications, but poor quality lenses and unreasonable installation methods will also cause New question. The material characteristics of the lens are determined by the wavelength and power of the laser. The substrate is generally made of fused quartz or crystalline silicon. The laser reflective film is generally made of silver film or transparent dielectric film, which has high reflectivity, low absorption rate and laser resistance. Characteristics of high damage threshold.

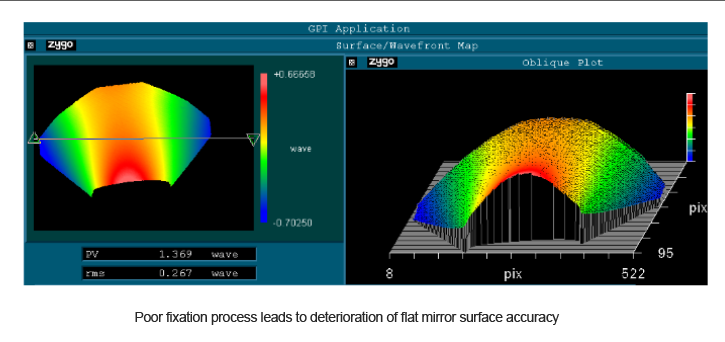

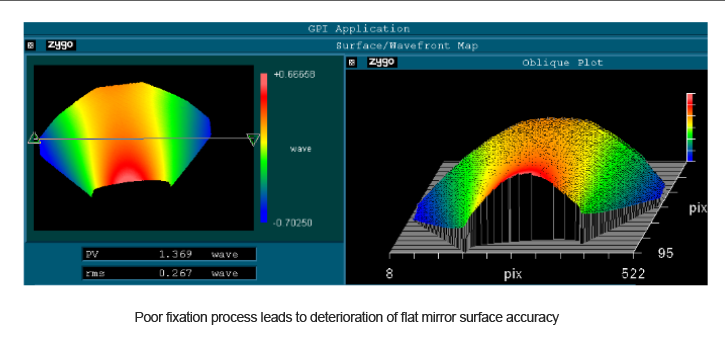

An ideal plane reflector will not affect the focus quality, but in actual use, the reflection plane may be deformed due to tension factors such as screw fixation, similar to a cylindrical mirror. The distortion mainly affects the focus spot quality, causing low-order astigmatism and other low-level astigmatism. Aberration prevents the focused spot from reaching the diffraction limit, affecting the processing quality and effect.

In kilowatt-level high-power MOPA pulse laser systems, we strongly recommend the use of high-quality quartz reflectors and appropriate installation methods to ensure that the lenses bear force without deformation.

Post time: Sep-13-2023