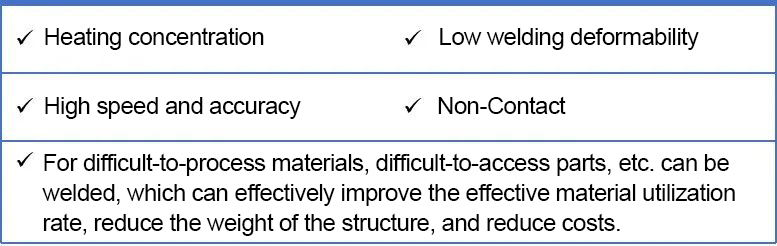

Laser joining technology, or laser welding technology, uses a high power laser beam to focus and regulate the irradiation of the material surface, and the material surface absorbs the laser energy and converts it into heat energy, causing the material to locally heat up and melt, followed by cooling and solidification to achieve the joining of homogeneous or dissimilar materials. The laser welding process requires a laser power density of 104 to 108 W/cm2. Compared to traditional welding methods, laser welding has the following advantages.

Laser joining technology, or laser welding technology, uses a high power laser beam to focus and regulate the irradiation of the material surface, and the material surface absorbs the laser energy and converts it into heat energy, causing the material to locally heat up and melt, followed by cooling and solidification to achieve the joining of homogeneous or dissimilar materials. The laser welding process requires a laser power density of 104 to 108 W/cm2. Compared to traditional welding methods, laser welding has the following advantages.

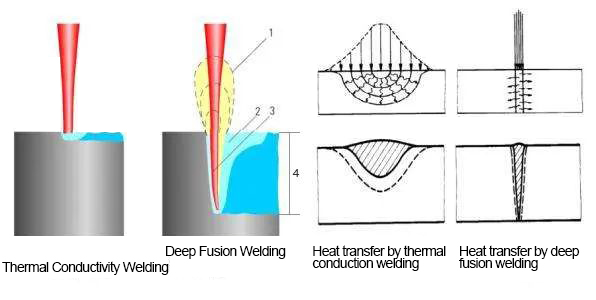

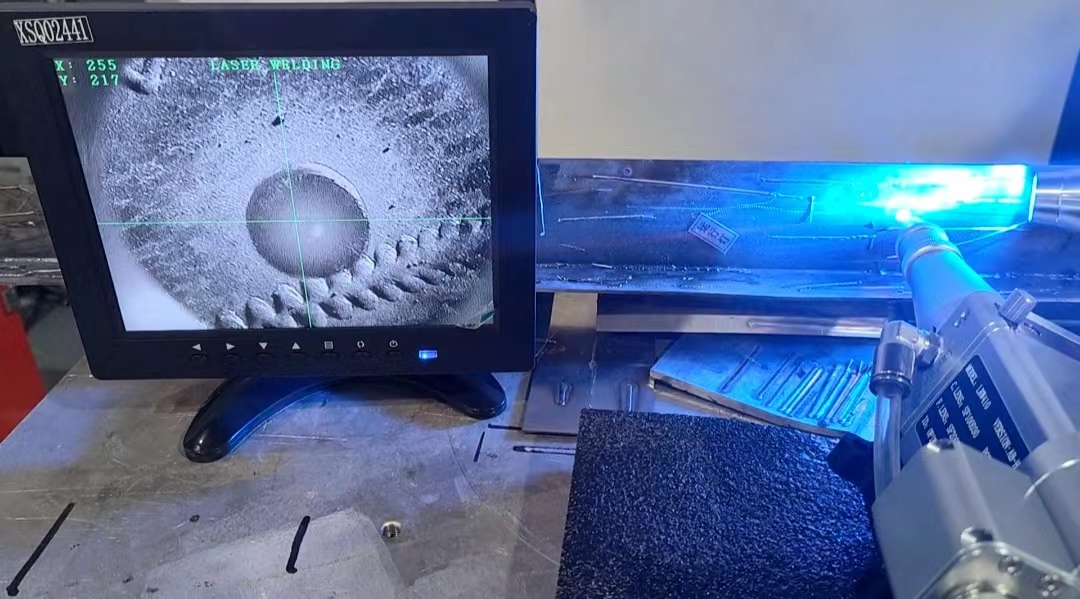

1-plasma cloud, 2-melting material, 3-keyhole, 4-depth of fusion

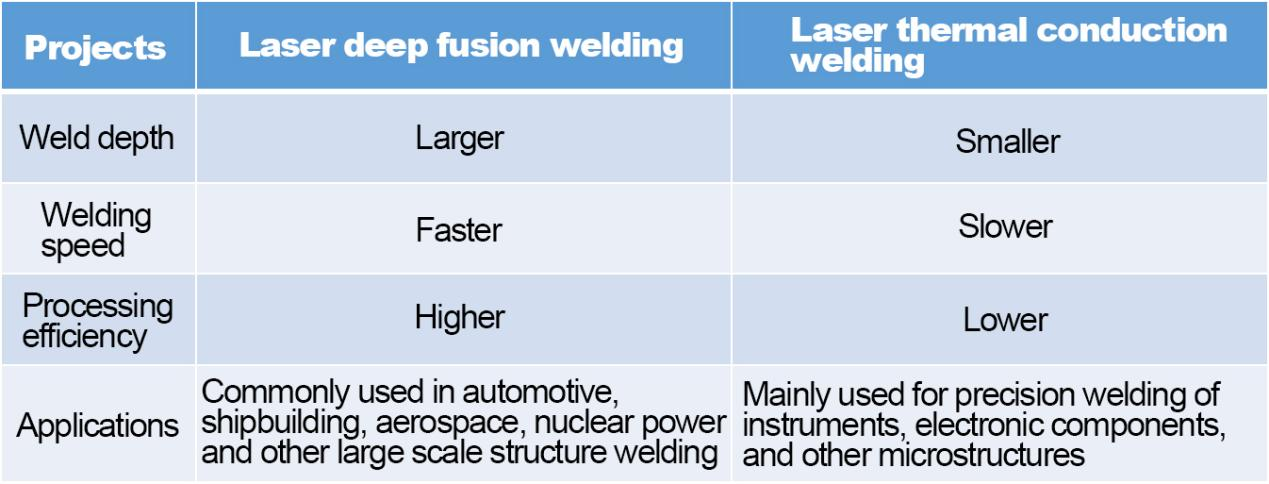

Due to the existence of the keyhole, the laser beam, after irradiating the inside of the keyhole, will increase the absorption of the laser by the material and promote the formation of the molten pool after scattering and other effects, the two welding methods are compared as follows.

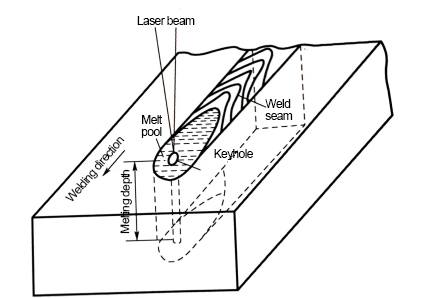

The above figure gives the laser welding process of the same material and the same light source, the energy conversion mechanism is only done through the keyhole, the keyhole and the molten metal near the wall of the hole moves with the advance of the laser beam, the molten metal moves the keyhole away from the air left behind to fill and after condensation, forming a weld seam.

If the material to be welded is a dissimilar metal, the existence of differences in thermal properties will have a great impact on the welding process, such as differences in melting points, thermal conductivity, specific heat capacity, and expansion coefficients of different materials, resulting in welding stress, welding deformation, and changes in the crystallization conditions of the welded joint metal, causing a decrease in the mechanical properties of the weld.

Therefore, according to the different characteristics of the welding scene, the welding process has developed laser filler welding, laser brazing, dual-beam laser welding, laser composite welding, etc.

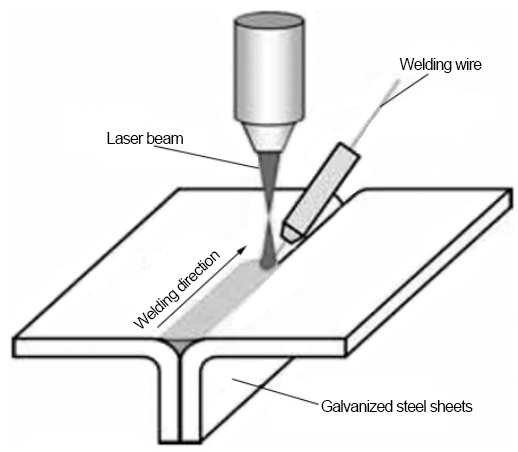

Laser Wire Filling Welding

In the laser welding process of aluminum, titanium and copper alloys, due to the low absorption of laser light (<10%) in these materials, the photo generated plasma has a certain shielding of laser light, so it is easy to form spatter and lead to the generation of defects such as porosity and cracks. In addition, the welding quality is also affected when the gap between workpieces is larger than the spot diameter during thin plate sputtering.

In solving the above problems, a better welding result can be obtained by using the method of filler material. The filler can be wire or powder, or a pre-set filler method can be used. Due to the small focused spot, the weld becomes narrower and has a slightly convex shape on the surface after the filler material is applied.

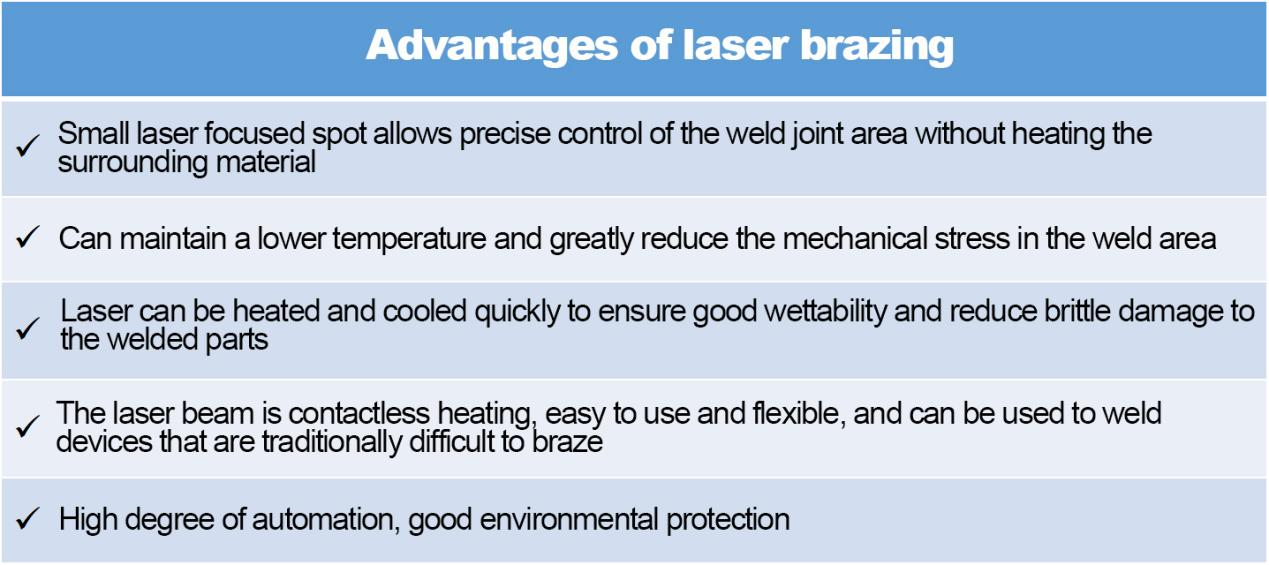

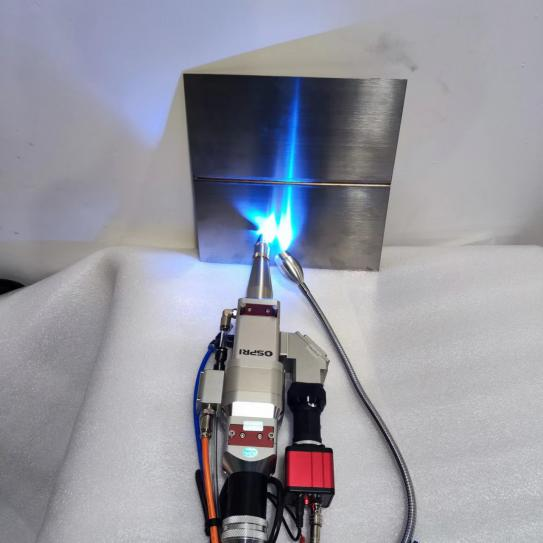

Laser Brazing

Unlike fusion welding, which melts two welded parts at the same time, brazing adds a filler material with a lower melting point than the base material to the weld surface, melts the filler material to fill the gap at a temperature lower than the base material’s melting point and higher than the filler material’s melting point, and then condenses to form a solid weld.

Brazing is suitable for heat-sensitive microelectronic devices, thin plates, and volatile metallic materials.

Further, it can be further classified as soft brazing (<450 °C) and hard brazing (>450 °C) depending on the temperature at which the brazing material is heated.

Dual Beam Laser Welding

Dual-beam welding allows flexible and convenient control of laser irradiation time and position, thus adjusting energy distribution.

It is mainly used for laser welding of aluminum and magnesium alloys, splice and lap plate welding for automobiles, laser brazing and deep fusion welding.

The double beam can be obtained by two independent lasers or by beam splitting with a beam splitter.

The two beams can be a combination of lasers with different time domain characteristics (pulsed vs. continuous), different wavelengths (mid-infrared vs. visible wavelengths) and different powers, which can be selected according to the actual processed material.

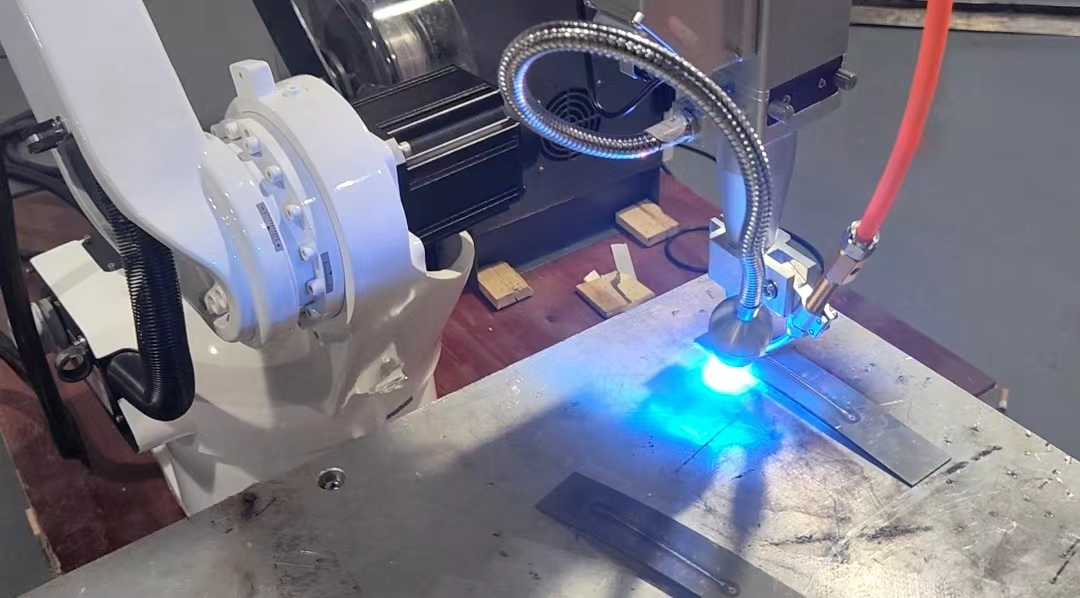

4.Laser Composite Welding

Due to the use of laser beam as the only heat source, single heat source laser welding has a low energy conversion rate and utilization rate, the weld base material port interface is easy to produce misalignment, easy to produce pores and cracks and other shortcomings, in order to solve this problem, you can use the heating characteristics of other heat sources to improve the heating of the laser on the workpiece, usually called laser composite welding.

The main form of laser composite welding is the composite welding of laser and electric arc, 1 + 1 > 2 effect is as follows.

after the laser beam near the applied arc, the electron density is significantly reduced, the plasma cloud generated by the laser welding is diluted, which can make the laser absorption rate greatly improved, while the arc on the base material preheating will further increase the absorption rate of the laser.

2. the high energy utilization of the arc and the total energy utilization will be increased.

3, the laser welding area of action is small, easy to cause misalignment of the welding port, while the thermal action of the arc is large, which can reduce the misalignment of the welding port. At the same time, the welding quality and efficiency of the arc is improved due to the focusing and guiding effect of the laser beam on the arc.

4, laser welding with high peak temperature, large heat-affected zone, fast cooling and solidification speed, easy to generate cracks and pores; while the arc’s heat-affected zone is small, which can reduce the temperature gradient, cooling, solidification speed, can reduce and eliminate the generation of pores and cracks.

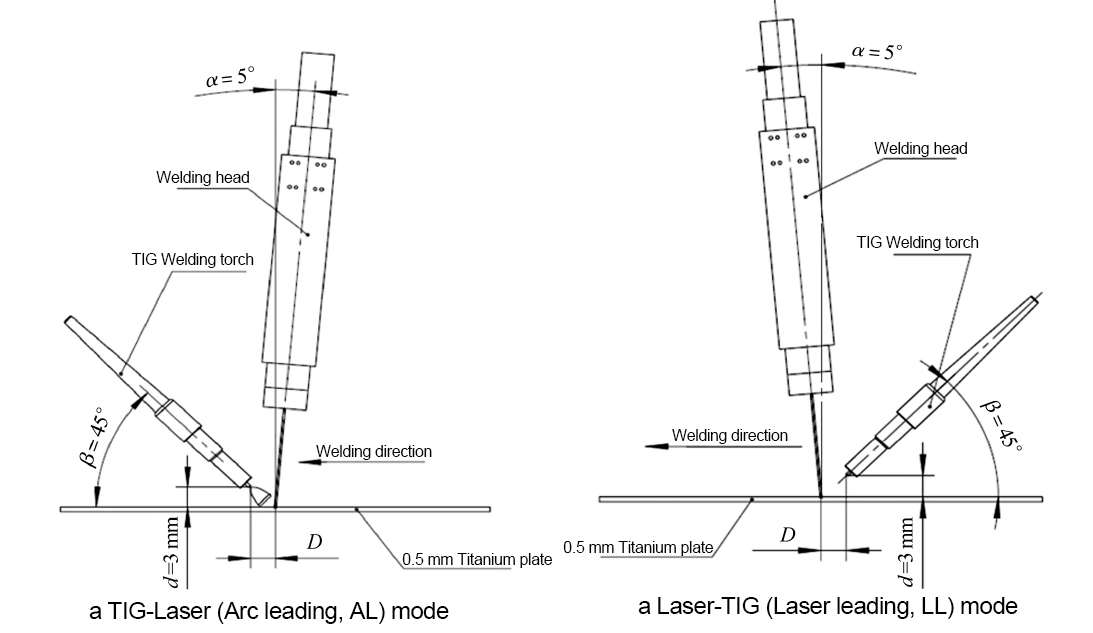

There are two common forms of laser-arc composite welding: laser-TIG composite welding (as shown below) and laser-MIG composite welding.

There are also other forms of welding such as laser and plasma arc, laser and inductive heat source compound welding.

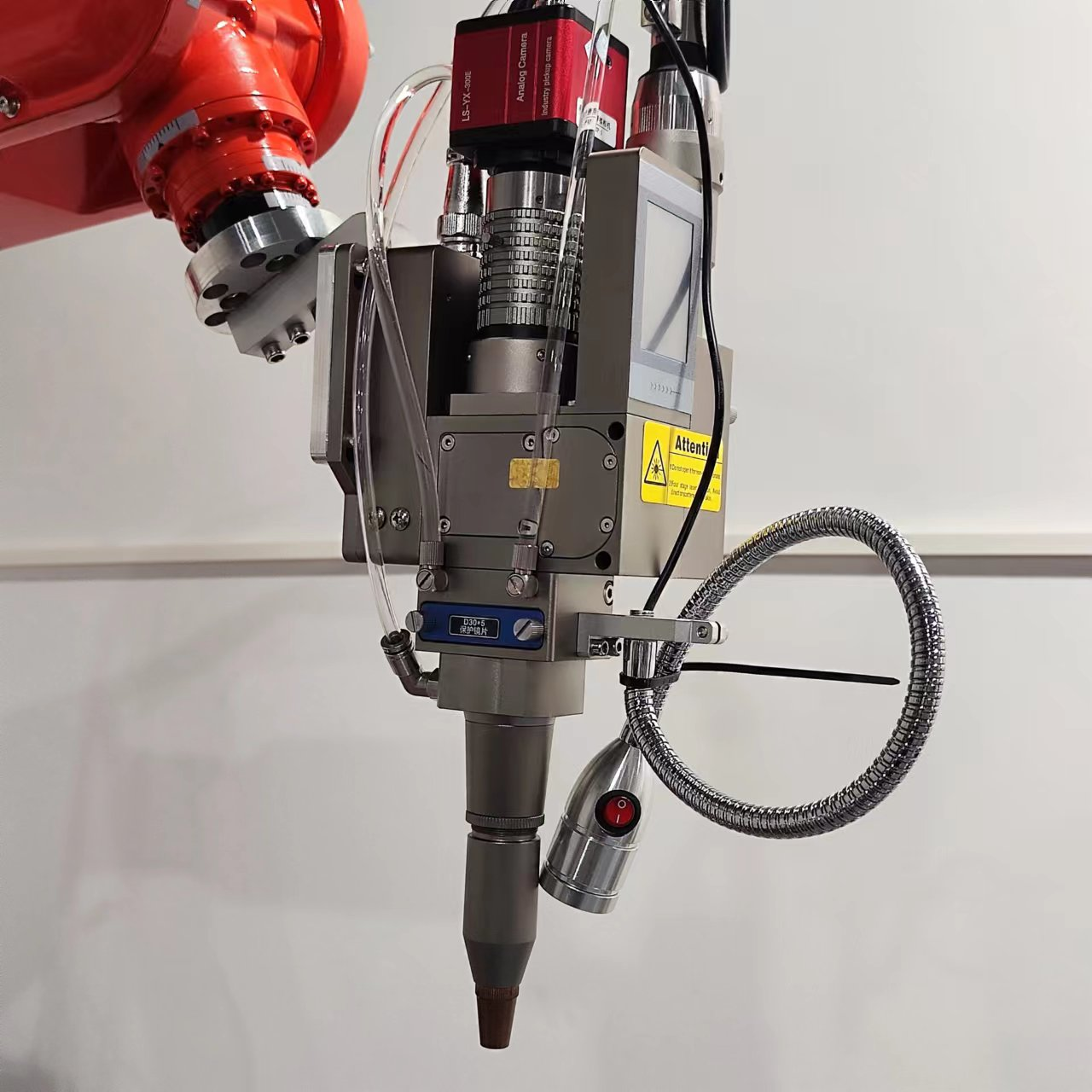

About MavenLaser

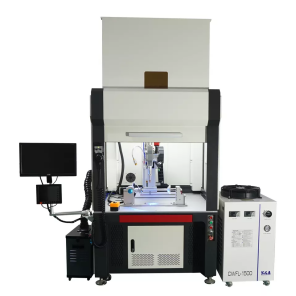

Maven Laser is the leader of laser industrialization application in China and the authoritative provider of global laser processing solutions. We deeply grasp the development trend of manufacturing industry, constantly enrich our products and solutions, insist on exploring the integration of automation, informationization and intelligence with manufacturing industry, provide laser welding equipment, laser marking equipment, laser cleaning equipment and laser gold and silver jewelry cutting equipment for various industries including full power series, and continuously expand our influence in the field of laser equipment.

Post time: Jan-13-2023