News

-

Laser Material Interaction – Keyhole Effect

The formation and development of keyholes: Keyhole definition: When the radiation irradiance is greater than 10 ^ 6W/cm ^ 2, the surface of the material melts and evaporates under the action of laser. When the evaporation speed is large enough, the generated vapor recoil pressure is sufficient ...Read more -

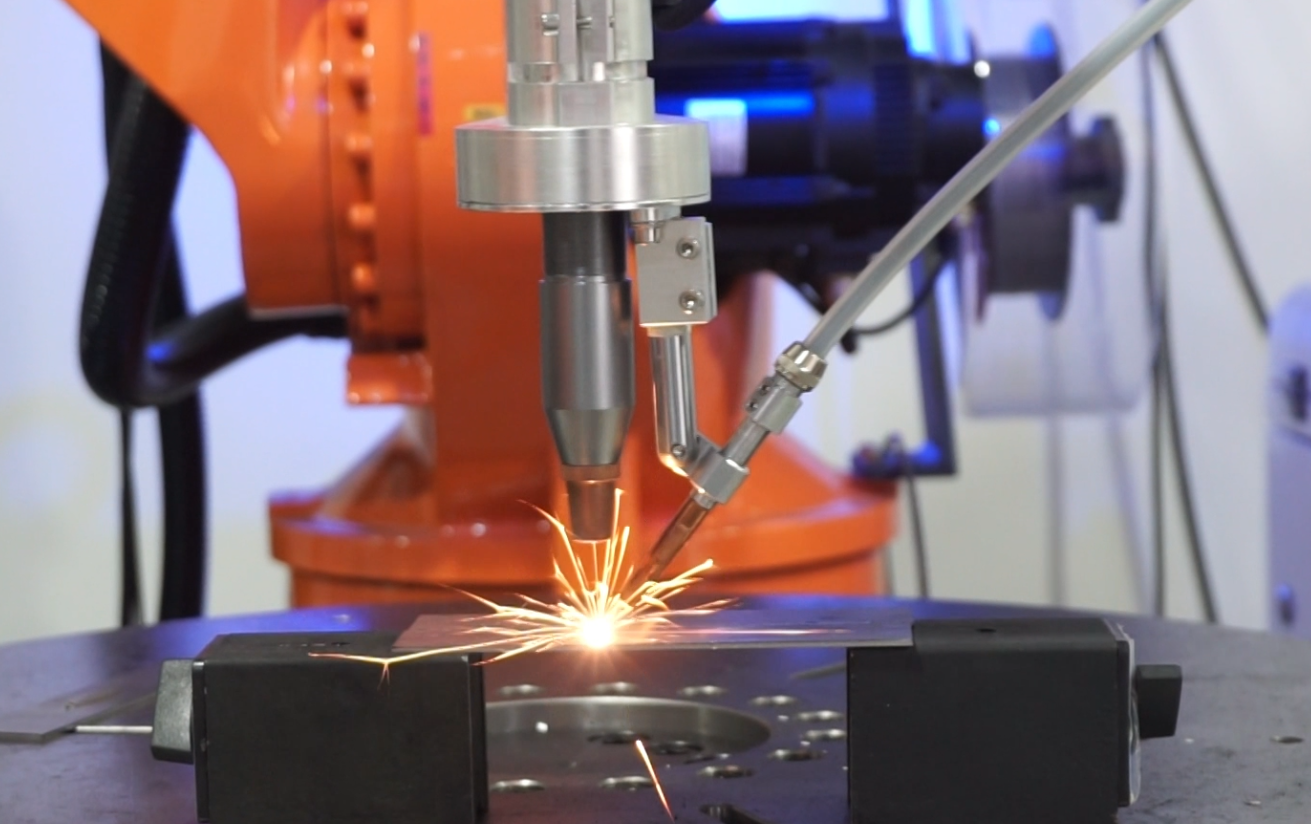

Manipulator laser welding machine: an automated and efficient manufacturing tool

Robot fiber laser welding machine is an automated laser welding equipment, which adopts a combination of manipulator and laser emitting device, which can realize the functions of automatic and precise positioning, welding, and processing of the workpiece. Compared with the traditional manual weld...Read more -

Laser welding focusing method

Laser welding focusing method When a laser comes into contact with a new device or conducts a new experiment, the first step must be focusing. Only by finding the focal plane can other process parameters such as defocusing amount, power, speed, etc. be correctly determined, so as to have a clear...Read more -

Laser absorption rate and changes in the state of matter of laser material interaction

The interaction between laser and materials involves many physical phenomena and characteristics. The next three articles will introduce the three key physical phenomena related to laser welding process in order to provide colleagues with a clearer understanding of the laser welding process: divi...Read more -

Introduction to Welding Robot: What are the safety precautions for welding robot operation

Welding robotic arm is an automated processing equipment that helps with the welding process by moving a robot on a workpiece. It is considered a highly efficient machine and is widely used in the welding industry. The safety operation precautions for welding robots are divided into different sta...Read more -

Application of Robot Welding Technology in Large Steel Welding

How is the robotic welding technology applied in large-scale steel welding? Welding robots are widely used by enterprises due to their stable welding quality, high welding accuracy, and efficient production. Large steel welding is increasingly using robots to replace traditional welding, in order...Read more -

Which is stronger, laser welding or traditional welding?

Do you think laser welding, with its faster processing speed and higher quality, may quickly occupy the entire processing technology field? However, the answer is that traditional welding will continue. And depending on your usage and process, traditional welding techniques may never disappear. S...Read more -

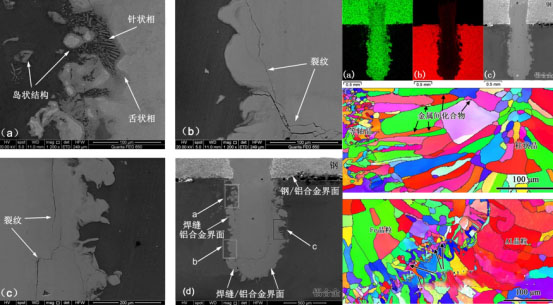

The Effect of Butt Joint Groove Form on Laser Arc Composite Welding of Medium and Thick Plate

01 What is a welded joint A welded joint refers to a joint where two or more workpieces are connected by welding. The welded joint of fusion welding is formed by local heating from a high-temperature heat source. The welded joint consists of a fusion zone (weld zone), fusion line, heat affected z...Read more -

What are the laser welding processes?

Laser welding is a new type of welding method. Laser welding is mainly aimed at welding thin-walled materials and precision parts. It can realize spot welding, butt welding, stack welding, seal welding, etc. Its characteristics are: high aspect ratio, The seam width is small, the heat affected zo...Read more -

History of laser development in China: What can we rely on to go further?

It has been more than 60 years since the first “beam of coherent light” was generated in a California laboratory in 1960. As the inventor of the laser, T.H. Maiman, said, “A laser is a solution in search of a problem.” Laser, as a tool, It is gradually penetrating into man...Read more -

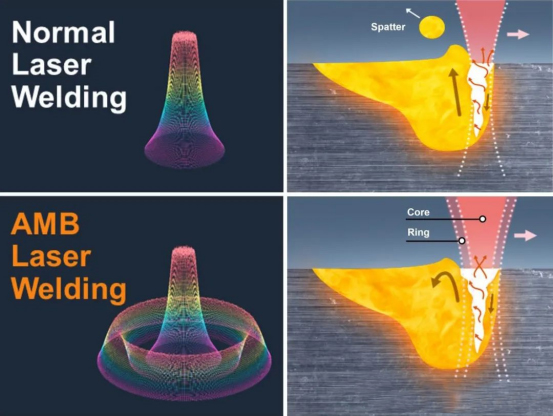

Single-mode-multi-mode-annular-hybrid laser welding comparison

Welding is a process of joining two or more metals together through the application of heat. Welding typically involves heating a material to its melting point so that the base metal melts to fill the gaps between the joints, forming a strong connection. Laser welding is a connection method that ...Read more -

Laser Storm – Future technological changes in dual-beam laser technology 2

1. Application examples 1)Splicing board In the 1960s, Toyota Motor Company first adopted tailor-welded blank technology. It is to connect two or more sheets together by welding and then stamp them. These sheets can have different thicknesses, materials, and properties. Due to the increasingly h...Read more