In January 2023, a number of Chinese companies announced expansion plans for power and energy storage batteries, with an investment amount approaching 100 billion yuan and a combined production capacity of 269 GWh, exceeding the combined production in the first half of last year (206.4 GWh) and almost covering last year's installed domestic power battery demand (294.6 GWh)

|

Enterprise |

Investment amount(Billion) |

Production capacity(GWh) |

|

BYD |

10 (Estimated) |

35 |

|

EVE BATTERY |

20.8 |

80 |

|

Ganfeng Lithium |

15 |

34 |

|

BAK BATTERY |

13 |

30 |

|

Farasis Energy |

10 |

30 |

|

Shenghong Group |

30.6 |

60 |

|

Total |

99.4 |

269 |

Data source: China Automotive News, network public data

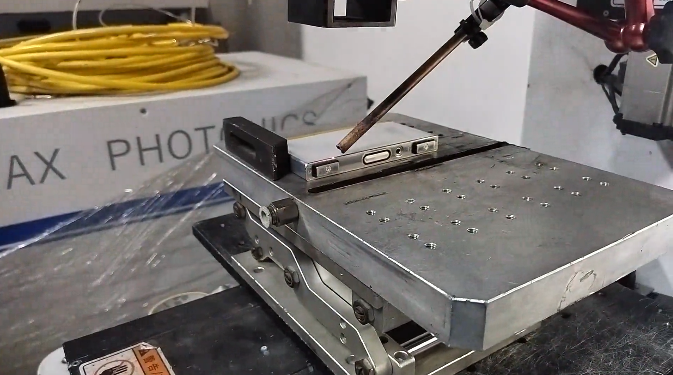

During the production of power batteries, the quality stability of the battery shell welding will affect the consistency and safety of the battery assembly system. The interior of the power battery shell mainly contains organic electrolyte, special diaphragm, and the cover mainly contains explosion-proof valve, pole post, safety cap, liquid injection hole, etc. The sealing welding between the shell and the cover is very demanding, and its welding quality directly affects the sealing degree of the battery, and poor welding will lead to battery leakage, lithium precipitation, and battery appearance is not up to standard.

▲Hard-shell square lithium battery soldering

01 Common welding seam problems

1- Bad appearance: welding bias, sand eyes, sample tilt

2- Inadequate strength and sealing: insufficient depth of fusion, cracks, large air holes resulting in battery leakage

02 Process analysis of welding seam problems

According to the FTA fault analysis, the welding failure problem is mainly summarized as bad appearance and welding strength problems. Bad appearance factors: welding equipment CCD scanning progress, protective gas type and flow rate, welding sample cleanliness, sample mechanical fit accuracy and way. Welding strength and sealing factors: raw material with precision, aluminum composition, the impact of process parameters.

|

Classification |

Questions |

Process Cause Categorization |

Specific reasons |

|

Appearance |

Partial welding |

Welding path Identification and positioning |

The CCD vision positioning process cannot accurately identify sample features, resulting in deviated welding trajectories, insufficient exposure of the auxiliary light source to the sample, and increased difficulty in photo positioning. |

|

Trachoma air hole |

The material itself and the welding environment |

Aluminum shell material composition, improper setting of protective gas type and flow rate, improper matching of top welding method and weld gap of cover and shell, insufficient cleanliness of side welding or top welding welding area. | |

|

Sample unevenness |

Sample assembly accuracy |

Cover and shell top welding method weld gap fit improperly, welding process stress accumulation. | |

|

Welding strength |

Battery leakage |

Sample size error and influence of welding parameters |

The cover and shell fit size is not stable, and the process parameters are not set accurately. |

03 The role of protective gas

Protective gas in the laser welding process can prevent oxidation of the metal surface, protect the lens, blow off the plasma, need to control the airflow direction, pressure, flow rate. The shielding gas forms turbulence, the weld will have porosity, uneven weld seam and other problems.

04 Different gas characteristics

The types of shielding gases for laser welding include helium, argon and nitrogen

Helium: High degree of ionization, the laser can pass through, all the beam energy reaches the surface of the workpiece, not easy to produce porosity, but expensive

Argon: lower price than helium, but it is susceptible to high temperature plasma ionization, although the protection effect is better, but will shield part of the laser energy processing, reduce the laser power, the use of helium welding surface appearance smooth

Nitrogen: low price, small ionization, welding swell will react with some elements of aluminum alloy to generate unstable compounds, affecting the welding strength

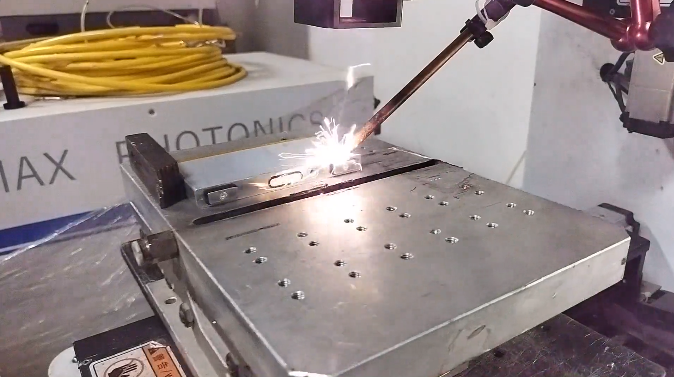

05 Analysis of the effect of different welding conditions

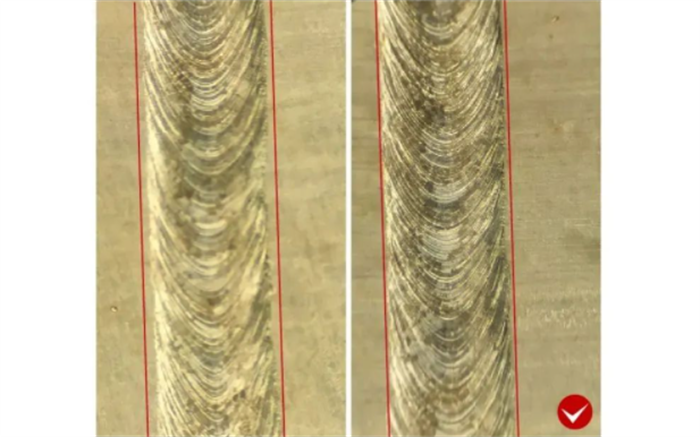

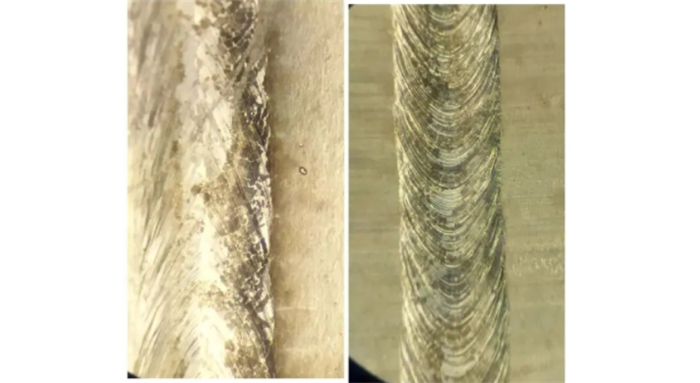

Welding with nitrogen and argon as shielding gas, when using nitrogen as shielding gas, the weld width consistency is poor, using argon as shielding gas, the weld opening is smooth, the fish scale pattern is evenly improved, and the appearance is better than using nitrogen welding products. (As shown in the figure below)

▲Different shielding gas welding effect (different seam width consistency)

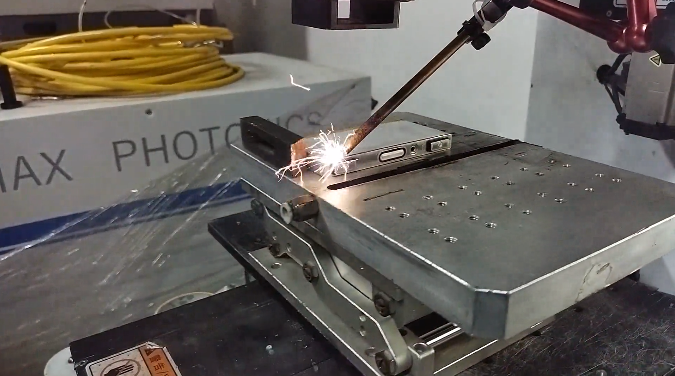

Laser power on the impact of welding, using the same welding speed and shielding gas, the higher the actual power output, the faster the weld material can be melted and vaporized, the melt pool fluidity increases, the fish scale pattern surface is more uniform, the weld seam is more flat. (As shown in the figure below)

▲Different power welding effect (different surface uniformity)

Summary

1. to the terminal site laser sealing equipment, CCD scanning positioning and welding parameters have an impact on the appearance of bad in the problem of partial welding.

2. Protective gas type and parameter settings can improve the uniform consistency of the weld, to ensure the cleanliness of the welding area, reduce the introduction of impurities foreign matter, can reduce the welding slag generated by the trachoma porosity.

3. Mechanical fit on the gap fit is better than interference fit, the field welding process first spot welding and then continuous welding way, can largely solve the gap fit when welding stability problems.

Maven Laser is a laser industry focused company, founded in 2008, now has 5 years of industry experience in the laser welding field, specializing in selecting the most suitable laser welding solutions and matching laser welding machines for you. In January, we launched our latest laser air-cooled handheld welding machine, which is now in a special promotion period, buy 5 units, the price of a single unit is as low as $4500, buy 10 units, the price of a single unit is as low as $4200. Air-cooled handheld welding is small, suitable for outdoor welding, and Maven's air-cooled handheld laser welding machine solves the current machine heat dissipation problem and can work for a long time without interruption. Welcome to your inquiry! We are Maven Laser, your professional laser partner.

Post time: Mar-03-2023