Robotic fiber laser welding machines have revolutionized the welding industry with their precision, flexibility and efficiency.

These machines combine the power of fiber lasers with the versatility of robotic arms for a wide range of applications across a variety of industries.

The Maven robotic laser welder is a prime example of this cutting-edge technology, offering unparalleled welding capabilities and flexibility.

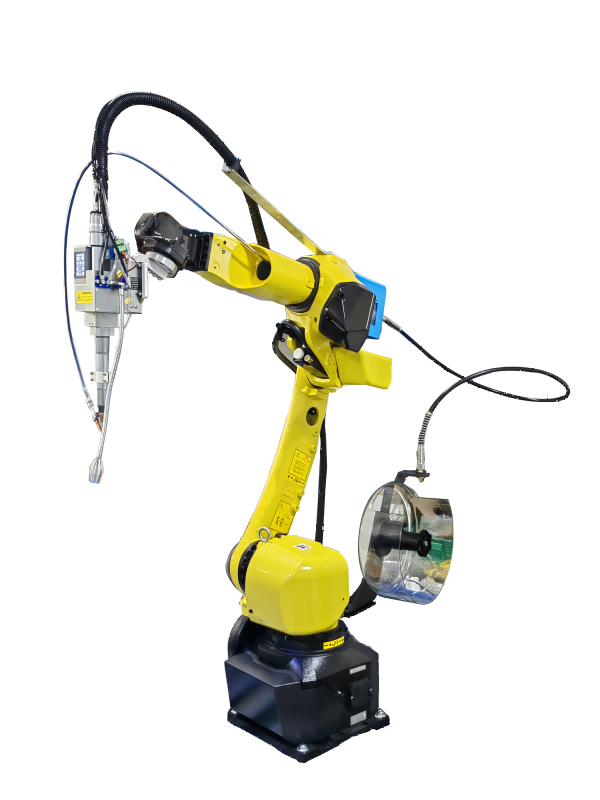

Maven robotic laser welding machine is equipped with a high-energy fiber laser beam that is seamlessly integrated with a six-axis robotic arm.

This combination enables precise control and movement, allowing the machine to weld along any trajectory in space.

This flexibility is unmatched by traditional welding machines, making the Maven robotic laser welder a valuable asset for manufacturers dealing with complex welding requirements.

One of the main advantages of the Maven robotic laser welder is its ability to weld parts that traditional welders typically cannot weld.

The robotic arms are programmed to get into tight spaces and complex geometries, ensuring that even the most complex parts can be welded accurately.

This feature provides manufacturers with maximum flexibility as they can confidently handle a variety of welding tasks with one machine.

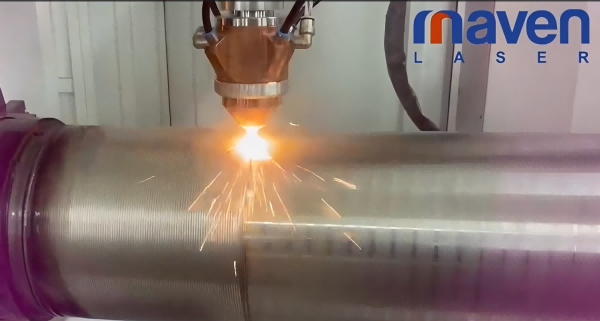

Additionally, the Maven robotic laser welder has the unique ability to split the laser beam in time and energy.

This innovation allows multiple beams to be processed simultaneously, significantly increasing welding productivity.

By harnessing the power of multiple laser beams, the machine can complete welding tasks more efficiently, resulting in higher output and shorter production times.

This feature is particularly valuable for high-volume manufacturing operations where speed and efficiency are critical.

Maven robot laser welding machine has a wide range of applications and far-reaching influence.

In the automotive industry, the machine is used to weld complex components of car bodies, exhaust systems and powertrains with unparalleled precision.

Its ability to reach hard-to-reach areas makes it an ideal solution for welding complex automotive parts, helping to improve the overall quality and durability of the final product.

In the aerospace industry, Maven robotic laser welders are used to weld critical components of aircraft structures, engines and propulsion systems.

The machine’s precision and flexibility make it ideally suited for the demanding requirements of aerospace manufacturing, where welding integrity is critical for safety and performance.

In addition, the machine is also used in the medical device industry and can be used to weld complex and precise components in medical devices and implants.

Its ability to handle complex geometries and tight tolerances makes it a valuable tool for manufacturers in the field, ensuring the production of high-quality medical devices that meet strict regulatory standards.

Maven robotic laser welders are also used in the electronics industry to weld small, complex components of electronic devices and circuits.

Its precision and ability to handle fine details make it an ideal solution for soldering precision electronic components, helping to improve the reliability and performance of electronic products.

In summary, the Maven robotic laser welder represents a significant advancement in welding technology, delivering unparalleled flexibility, precision and productivity.

Its ability to weld along any trajectory in space, access hard-to-reach areas, and handle multiple laser beams simultaneously makes it a versatile and valuable asset to manufacturers in a variety of industries.

With its wide range of applications and innovative features, the Maven robotic laser welding machine is expected to continue to drive the advancement of welding technology and meet the ever-changing needs of modern manufacturing.

Post time: Aug-22-2024