Mold remediation is a critical process in the manufacturing industry, and having the right tools and equipment is critical to achieving high-quality results.

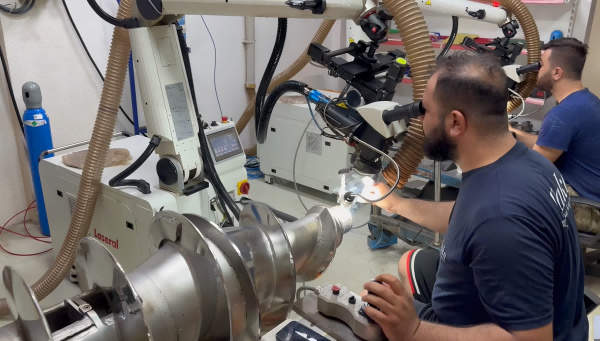

One such tool that has become popular in recent years is the QCW mold repair fiber welder.

This innovative machine revolutionizes the mold remediation process, offering a range of benefits and features that make it the first choice for manufacturers and mold remediation professionals.

In this article, we will explore the features of mold welding machines and delve into what makes the QCW Mold Repair Fiber Welding Machine stand out.

Mold welding machines are designed to repair and repair molds used in various manufacturing processes.

These machines utilize advanced welding technology to repair cracks, chips and other damage to molds, ensuring they can continue to produce high-quality parts.

When choosing a mold welding machine, there are several key features to consider. These include precision, efficiency, versatility and ease of use.

The QCW Mold Repair Fiber Welding Machine excels in all of these areas, making it the best choice for mold repair professionals.

Let’s take a closer look at the features that set this machine apart from the competition.

Precision is a key factor in mold repair because even the smallest defects can affect the quality of the finished part.

The QCW mold repair fiber optic welding machine is equipped with advanced laser technology for precise and accurate welding.

This level of precision ensures that the repaired mold maintains its original dimensions and specifications, producing parts that meet the highest quality standards.

Efficiency is another important feature of mold welding machines.

The QCW mold repair fiber optic welding machine features fast welding speeds, enabling quick repairs and minimizing downtime during manufacturing.

This efficiency is critical to maintaining productivity and meeting production deadlines, making QCW machines a valuable asset for manufacturers.

Versatility is also a key consideration when selecting a mold welding machine.

The QCW mold repair fiber welder is capable of repairing a variety of mold materials, including steel, aluminum and various alloys.

This versatility makes it suitable for a variety of manufacturing applications, providing flexibility for mold remediation professionals.

Ease of use is a key factor with any equipment, and the QCW Mold Repair Fiber Welding Machine is designed with user-friendly features that allow operators of varying skill levels to use it. Intuitive controls, ergonomic design and comprehensive training and support ensure users can master the machine quickly and achieve optimal results

In addition to these features, there are several specific reasons why the QCW Mold Repair Fiber Welder is the first choice of mold repair professionals.

One of the main advantages of this machine is the ability to perform repairs without the need for extensive preheating or post-weld heat treatment.

This not only saves time, it also minimizes the risk of thermal deformation and maintains the integrity of the mold.

In addition, the QCW mold repair fiber welding machine features superior welding strength and quality, ensuring that repaired molds can withstand the rigors of continuous use during the manufacturing process.

This durability is critical to maximizing the life of the mold and reducing the frequency of repairs, ultimately saving time and money for manufacturers.

Another compelling reason to choose a QCW mold repair fiber welder is its ability to achieve seamless welds with minimal material buildup.

This results in a clean, precise finish without the need for extensive post-weld finishing and polishing.

QCW machines are capable of producing high-quality welds with minimal material distortion, which sets QCW machines apart from traditional welding methods.

In addition, the QCW mold repair fiber welding machine is equipped with advanced monitoring and control systems to ensure consistent welding quality and minimize the risk of defects.

This level of automation and precision reduces reliance on operator skill and experience, making the machine accessible to a wider range of users.

In summary, the QCW Mold Repair Fiber Welding Machine combines precision, efficiency, versatility and ease of use, making it the first choice for mold repair professionals.

Its ability to provide high-quality welds, minimal thermal distortion, superior strength and a seamless finish makes it an excellent solution for mold repair.

With QCW machines, manufacturers can achieve reliable and long-lasting repairs, ultimately helping to increase productivity and save costs.

When it comes to mold repair, choosing the right equipment is crucial, and the QCW Mold Repair Fiber Welding Machine is undoubtedly the leading choice in the industry.

Post time: Sep-06-2024

.png)

.png)

.png)