Portable UV Laser Marking Engraving Machine for Plastic Glass

High precision, high speed, stable performance

Good attainment and high precision

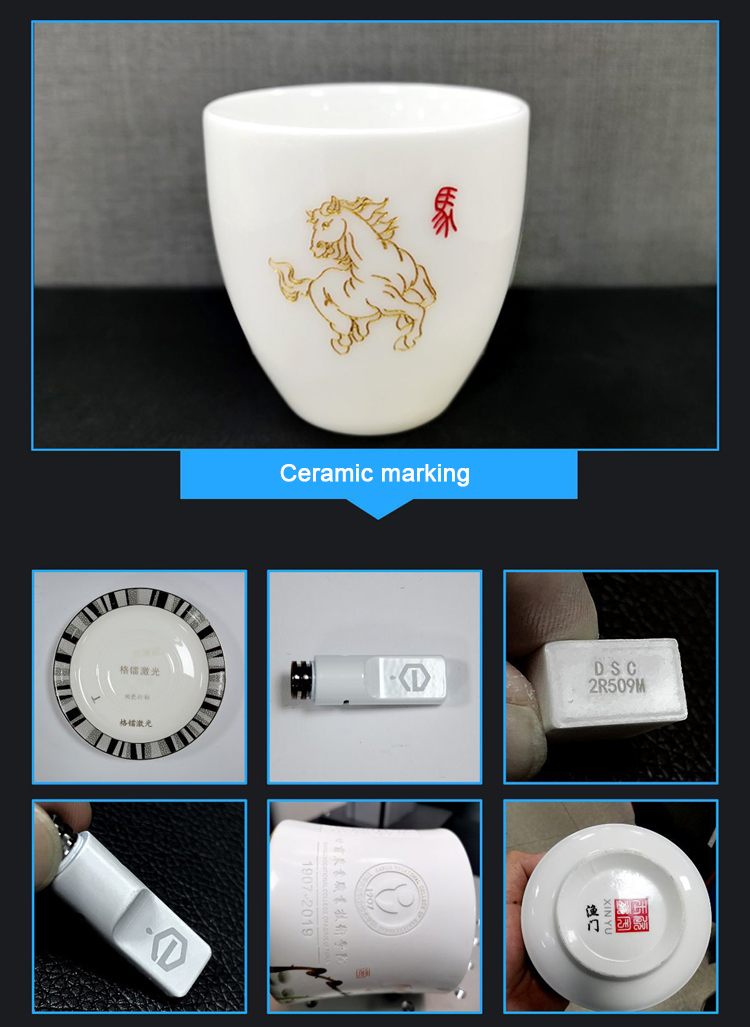

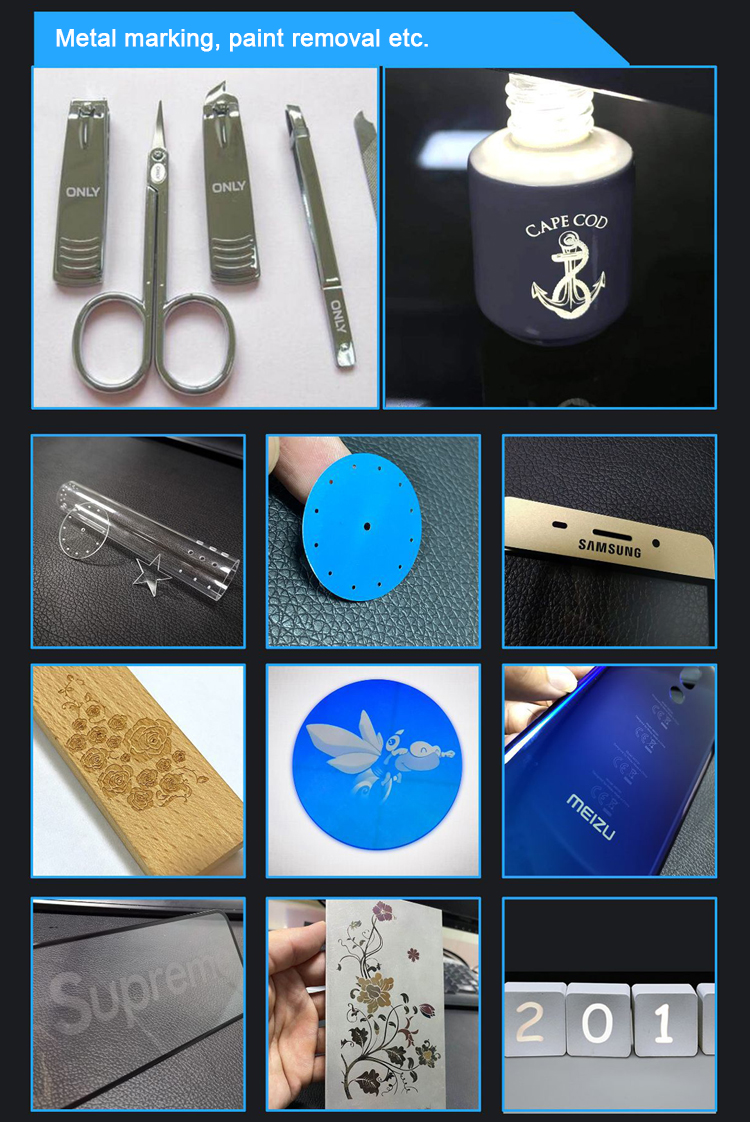

Logo, pattern, text laser engraving

Jade, glass, ceramics, porcelain, jade, plastic, silicone, metal and other products laser engraving

Compact Bench-top

3W UV Laser Marking Machine

Long-term working stability,24/7 industrial application

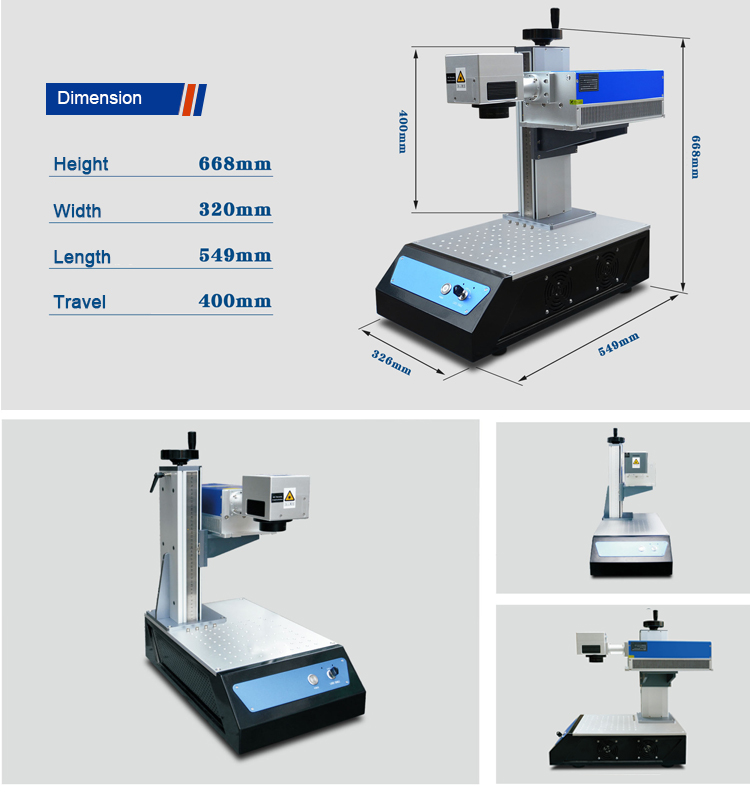

Height 668mm

Width 320mm

Length 549mm

Travel 400mm

| Product Name | UV Laser Marking Machine for Plastic Glass |

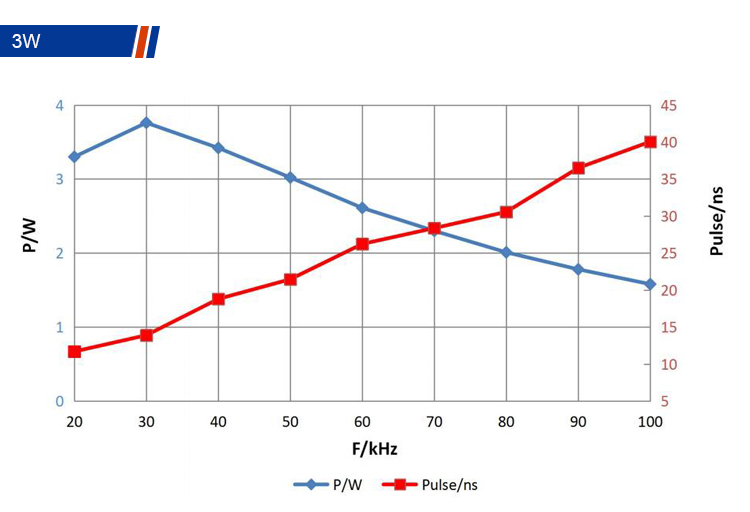

| Laser Power | 3W 5W 10W |

| Laser Wavelength | 355nm |

| Frequency Range | 40KHz-300KHz |

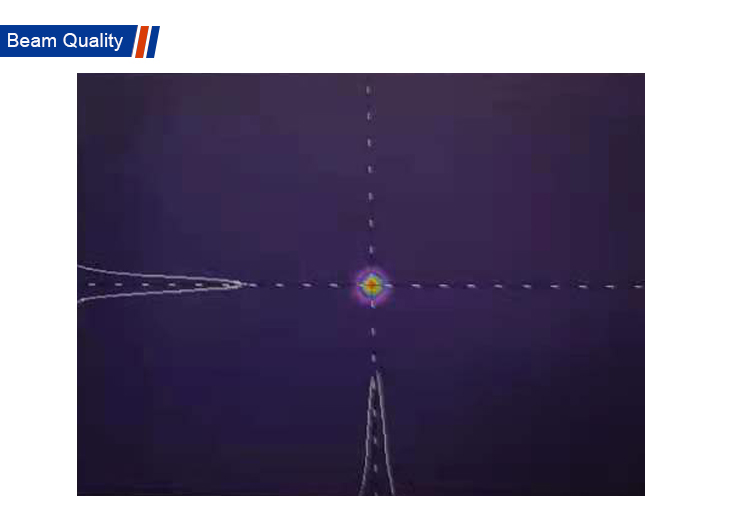

| Beam Quality(M2) | M2≤1.2 |

| Beam Diameter | 0.8±0.1mm |

| Average Power Stability | RMS≤3%@24hr |

| Average Power Consumption | <250W |

| Laser Marking Area | 50*50mm/110*110mm/150*150mm |

| Laser Marking Speed | 2000-15000mm/s |

| Cooling Mode | Air cooling/Water cooling |

| Power Input | <1000W |

| Voltage Requirement | 90V-240V 50/60HZ |

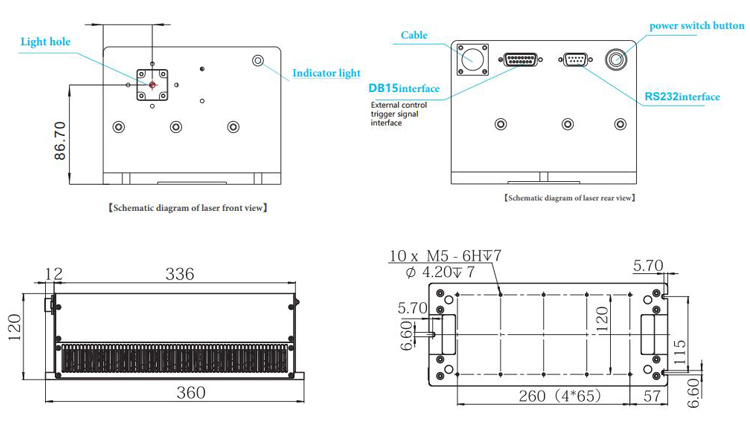

| Communication Interface | USB |

| Life-span | 100000 hours |

| Optional Device | Laser protective goggles,T-slot, Rotary device,Jack |

| Graphic Format Supported | AI,PLT,DXF,DWG |

| Control Software | JCZ Ezcad |

| Weight(KG) | 40KG |

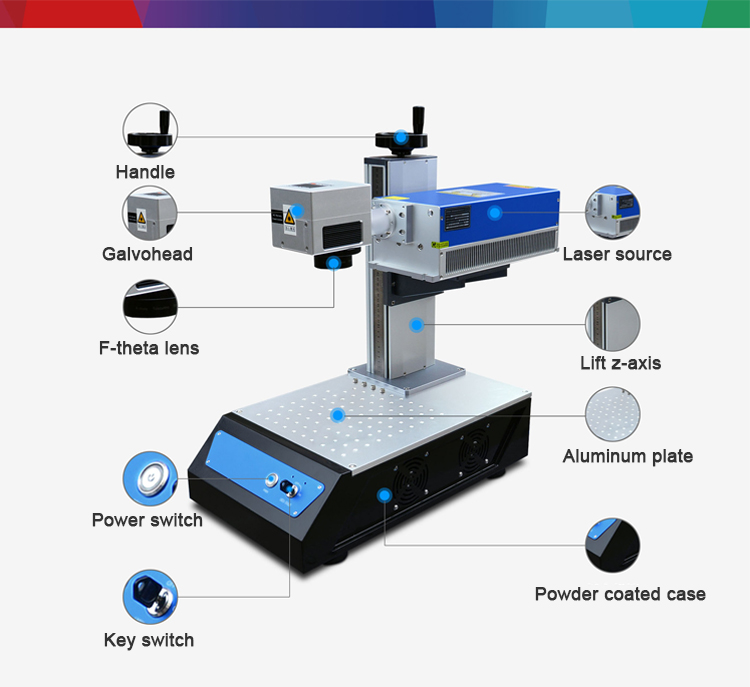

| Configuration | Bench-top |

| Lifespan of laser device | 100000 hours |

| Mode of Operation | Continuous Wave |

Compact Bench-top

3W UV Laser Marking Machine

Long-term working stability,24/7 industrial application

Height 668mm

Width 320mm

Length 549mm

Travel 400mm

MavenLaser UV laser marking machine using 355nm ultraviolet laser developed, the machine uses the third-order intracavity frequency doubling technology compared with infrared laser, 355 UV focused spot is very small, the effect of marking is to directly interrupt the molecular chain of the material through the short wavelength laser, greatly reducing the mechanical deformation of the material, heat deformation (is a cold light), because mainly used for ultra-fine Marking, engraving, especially suitable for food, pharmaceutical packaging materials marking, punching micro-hole, high-speed division of glass materials and complex graphics cutting of silicon wafers and other application industries. Our company uses the international advanced technology, UV laser is pumped by high power multi-mode laser diode to produce laser and then multiply the UV laser beam, and then through computer control of high-speed scanning mirror deflection to change the laser beam optical path to achieve automatic marking.