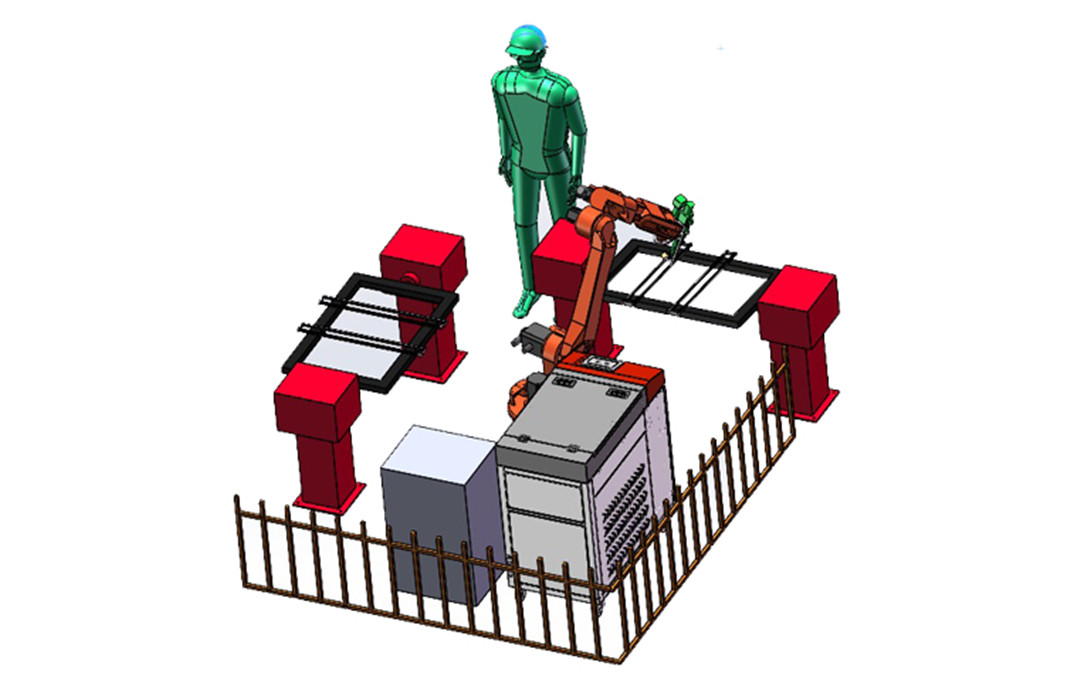

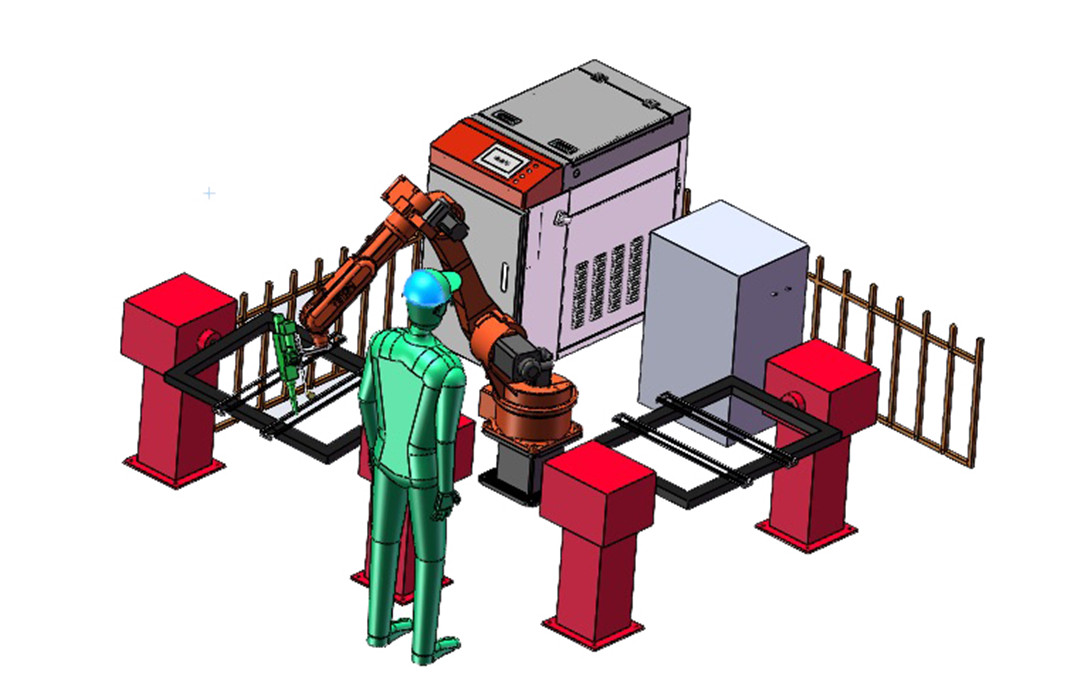

Robotic Fiber Laser Welding Machine

Equipment Features:

1. Using robotic movement, suitable for large-format space welding, can be six-axis linkage.

2. Can weld in any space, truly realize the automatic welding of any trajectory in space.

3. High repetition accuracy, can repeat the welding for many times without error, the quality of the weld is more stable.

4. It can replace manual operation, and can laser weld complex and dangerous fields.

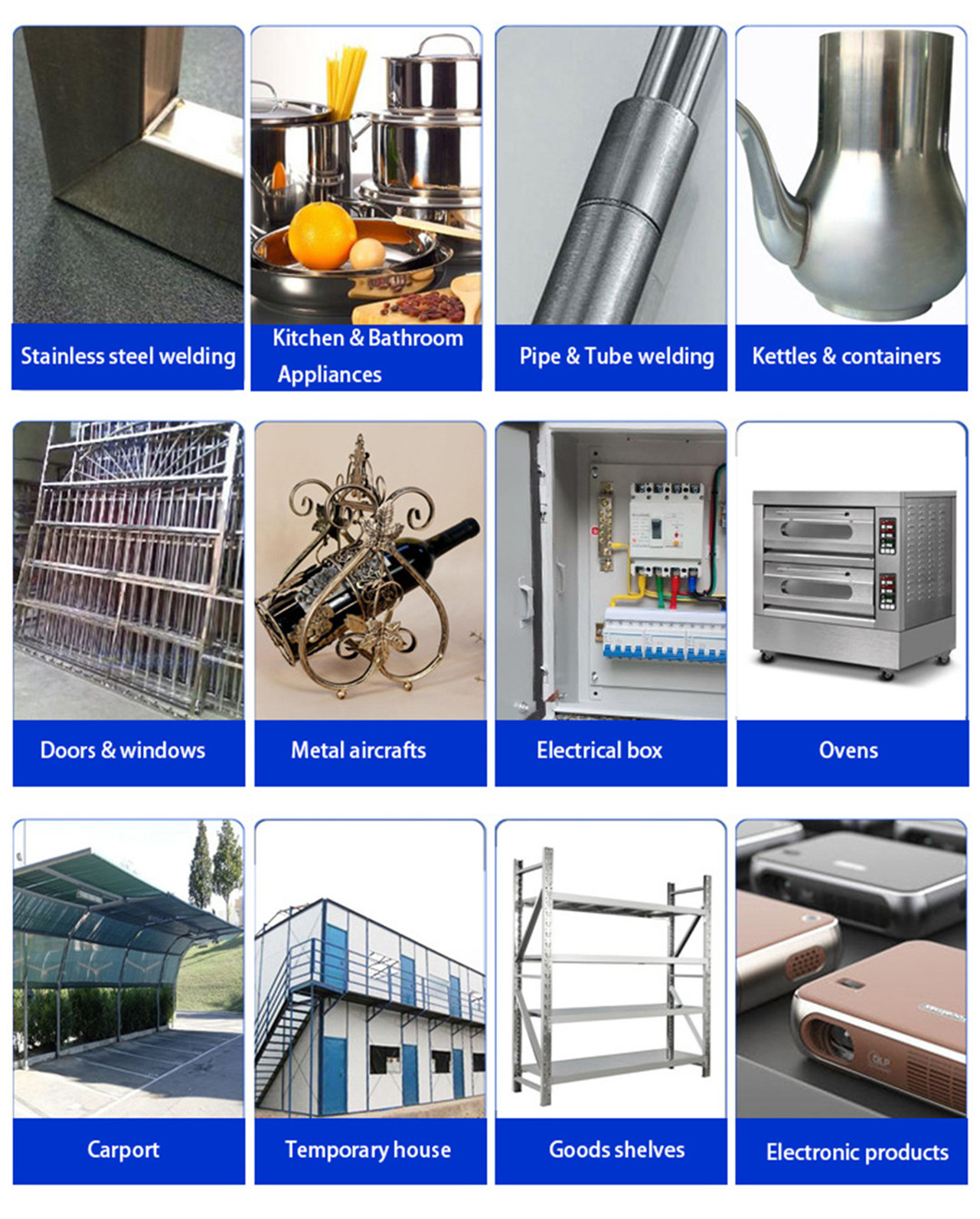

Application areas:

Auto body, auto steel plate, clutch plate, difficult and complex welding fields, microelectronic components, precision parts, high-grade digital components, fiber optic connectors, medical devices, large mold welding, injection molding and other welding.

PROFESSIONAL WELDING SOLUTION

Wire Feeder and Welding Concentrated on the Control Pedal

0.08mm Robot Positioning Accuracy

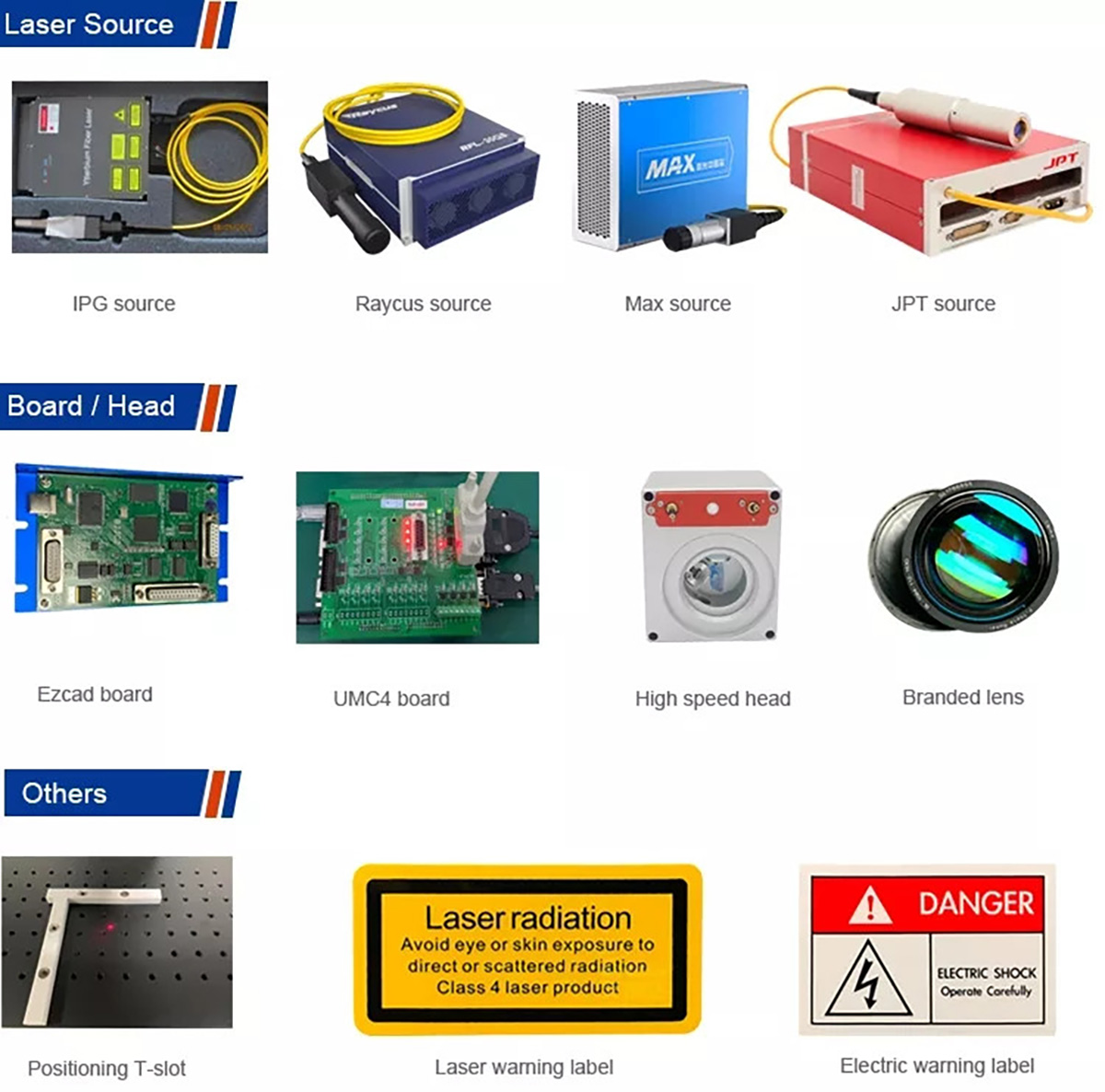

Raycus Max JPT IPG Laser Source Optional

Customization of Whole System

| Product Name | Robot Automatic Laser Welding Machine MLA-W-A01 |

| Wavelength | 1070+/-10 nm |

| Laser Power | 1000W 1500W 2000W 3000W |

| Power Adjustment | 10-100% |

| Fiber Length | Standard 10m or Specify |

| Working Methods | CW/Pulse |

| Speed Range | 0-120 mm |

| Weld Thickness | 0.5-6 mm |

| Welding Gap Requirement | < 1 mm |

| Modulation Frequency | 20KHZ |

| Turn on/off Time | 20 Us |

| Working Temperature | 15-35 ℃ |

| Power Supply | 220V/50HZ/30A |

| Chilling Methods | Water Chilled Inbuilt |

| Machine Size | 990*540*1030 mm |

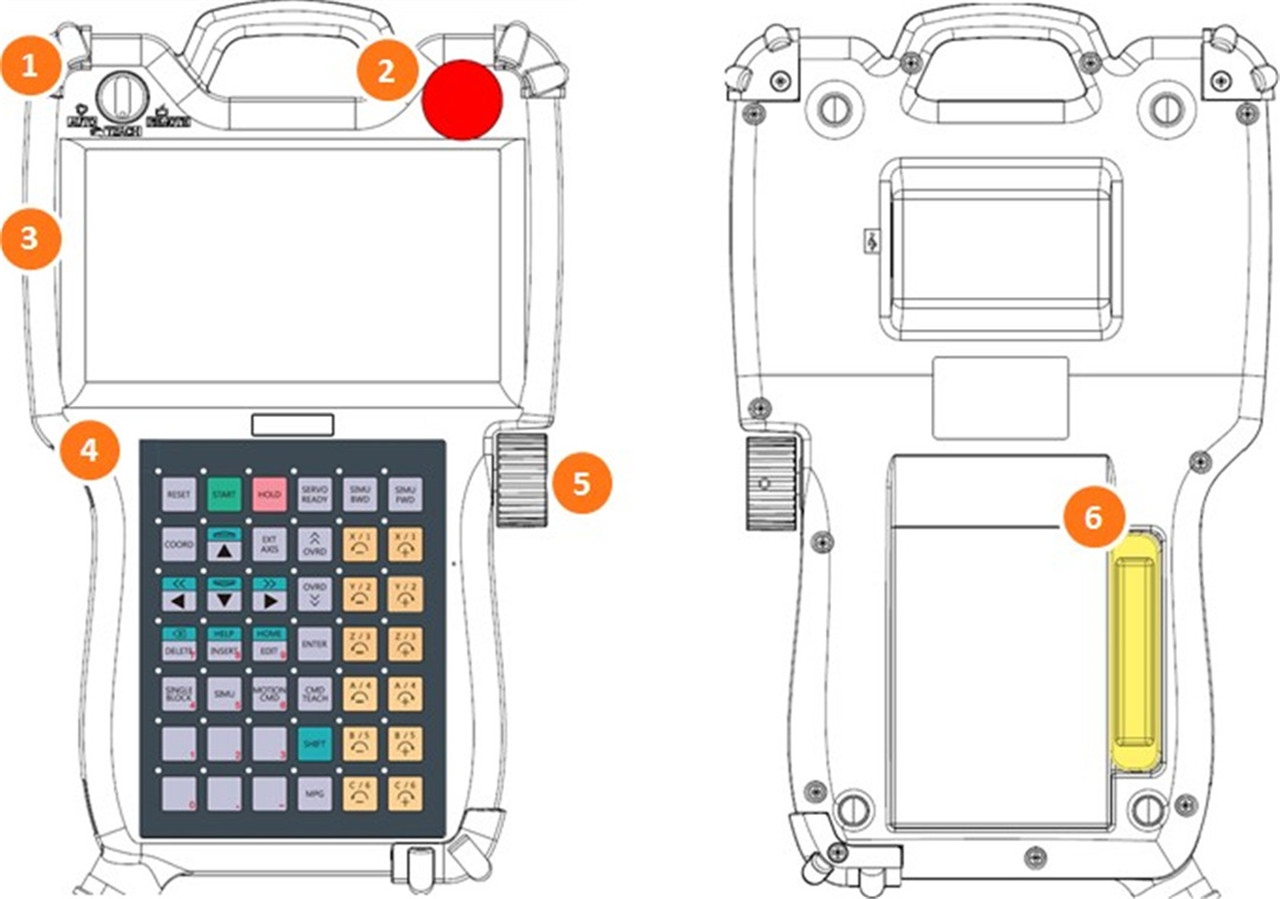

EASY TO OPERATE

Friendly use controller for easy cooperation with fiber laser welding workmanship instruction

CONTROL INTERGRATION

The control cabinet integration is to control the wire feeding function. And the laser power can rises and falls slowly to prevent over burning. The slow rise and fall is especially advantageous for thin plate welding. When the manipulator is finishing, it is generally easier to weld through the plate.

LASE INTERGRATUION

In addition to adjusting the welding parameters in the laser system. It also has the functions of each system status indicator light, electric water change, and automatic reminder to protect the lens.

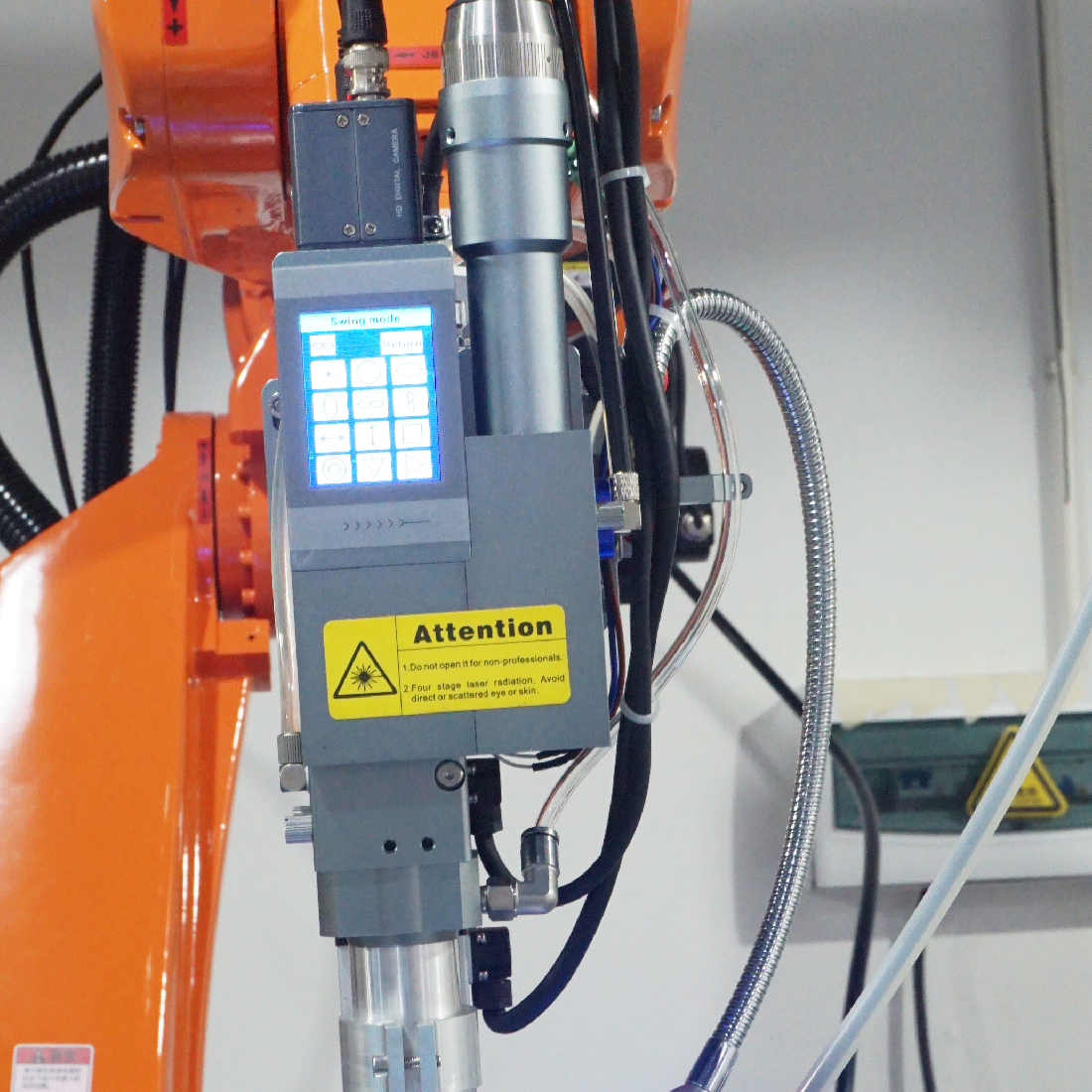

HEAD INTERGRATION

Integrated welding head, CCD on the head, adjustable power, auto focus, convenient operation.

EASY TO OPERATE

The buttons of the teach pendant are simple and easy to understand, and the teaching programming can be learn and use quickly. If the operation is wrong, the machine automatically stops to avoid the risk of equipment damage.

WORK EFFICIENTLY

Once programmed, it can be used all the time. MavenLaser Robot Arm supports 24 hours of continuous work with high precision and high speed. Fully automated operation, a robot can complete the workload of more than 2-3 people a day.

LOW COST

One-time investment, long term benefits. The service life of MavenLaser robot is 80,000 hours, which is equivalent to more than 9 years of 24-hour uninterrupted work. It greatly saves labor costs and personnel management costs, and solves problems such as difficulty in recruiting people.

SAFE AND RELIABLE

MavenLaser robot arm is equipped with photoeletric safety protection measures. When foreign objects enter the work area, it can automatically alarm and suspend work to avoid accidental in worker.

SAFE ENERGY AND SPEACE

MavenLaser automation equipment line layout is simple and tidy small footprint, no noise, light and strong robot arm, low power consumption, energy saxing and environmental protection.

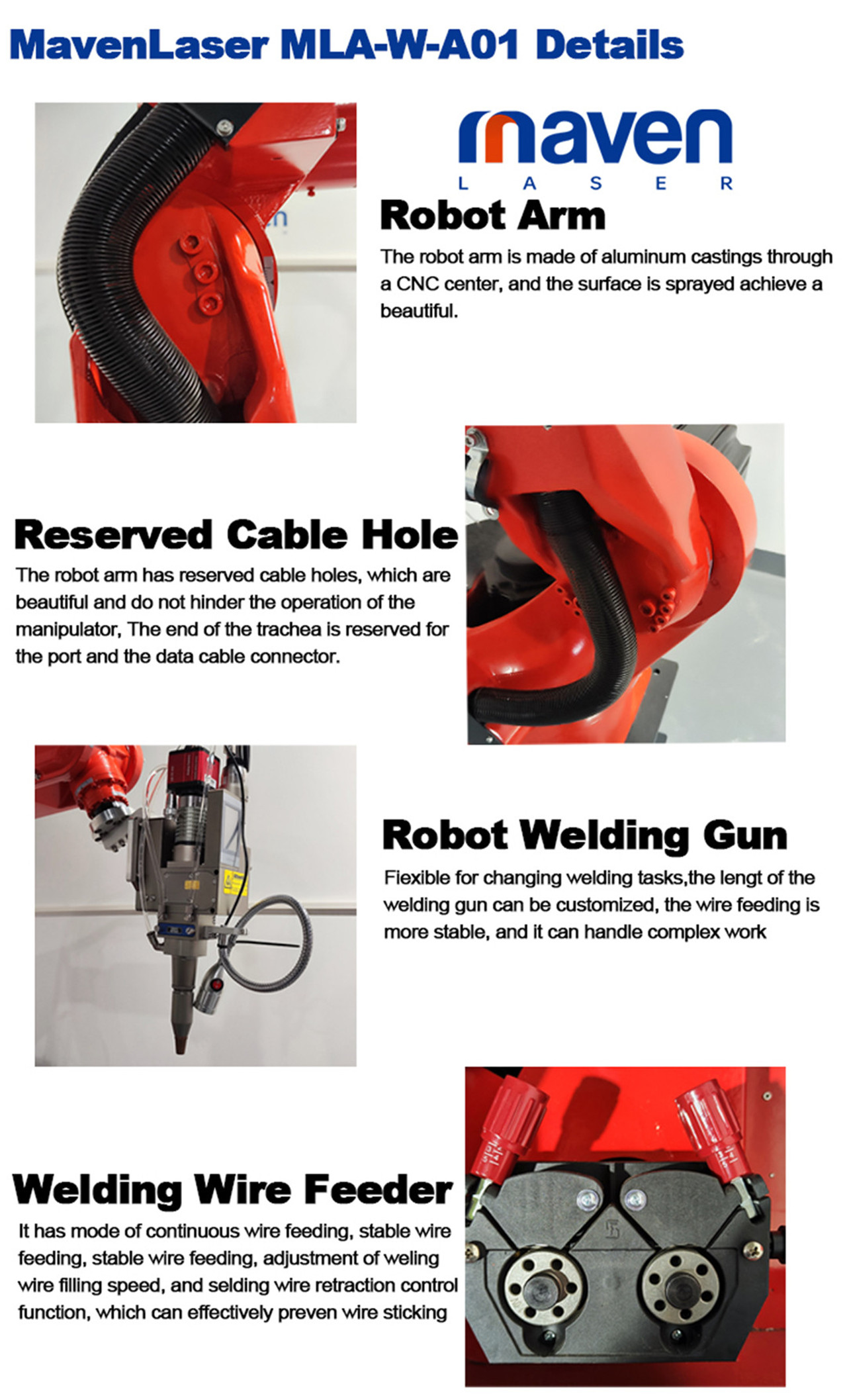

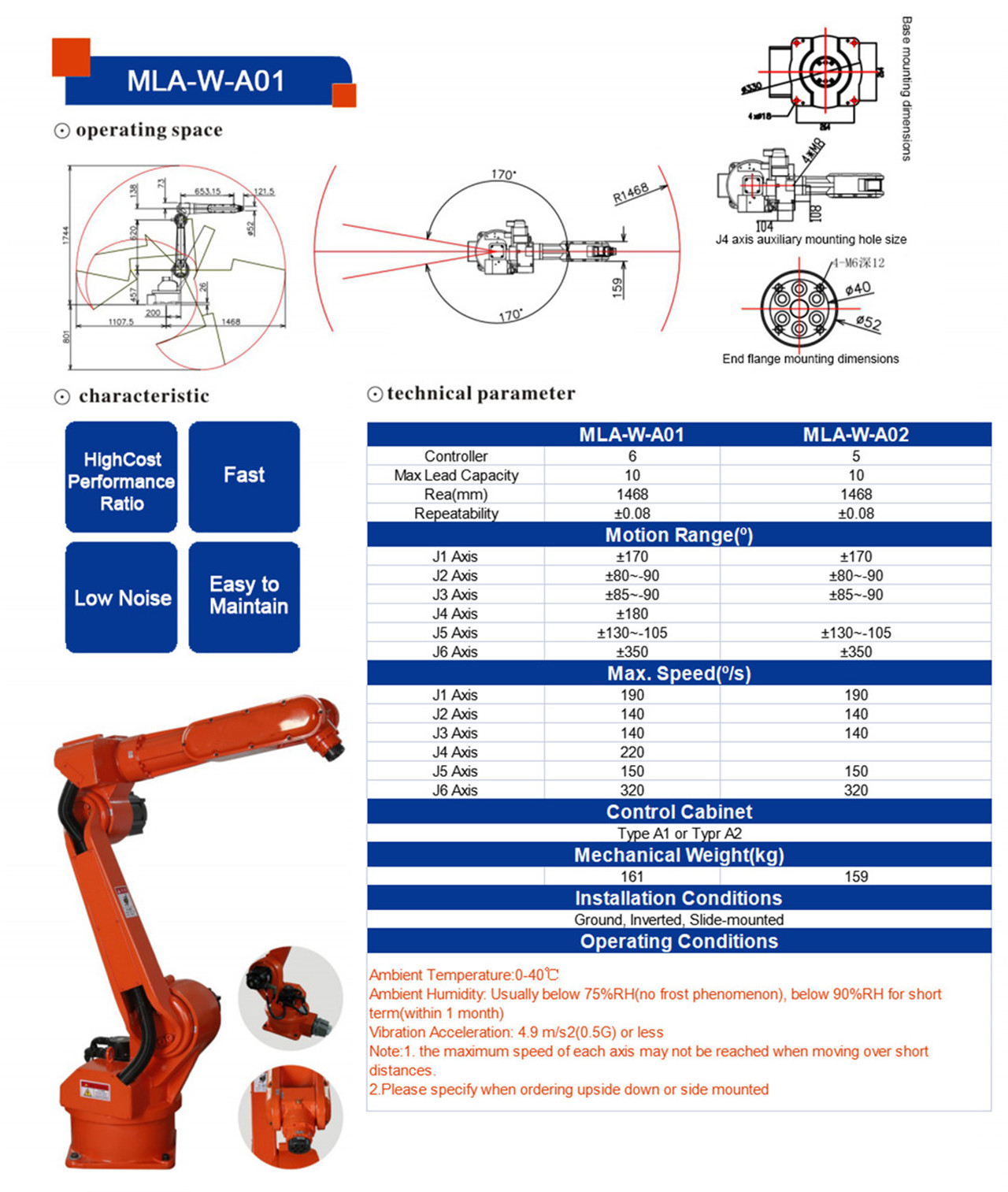

Robot Arm

The robot arm is made of aluminum castings through a CNC center, and the surface is sprayed achieve a beautiful.

Reserved Cable Hole

The robot arm has reserved cable holes, which are beautiful and nit hinder the operation of the manipulator, the end of the trachea is reserved for the port and the data cable connector.

Robot Welding Gun

Flexible for changing welding tasks, the length of the welding gun can be customized, the wire feeding is more stable, and it can handle complex work.

Welding Wire Feeder

It has mode of continuous wire feeding, stable wire feeding, stable wire feeding, adjustment of welling wire filling speed, and selding wire retraction control function, which can effectively preven wire sticking.

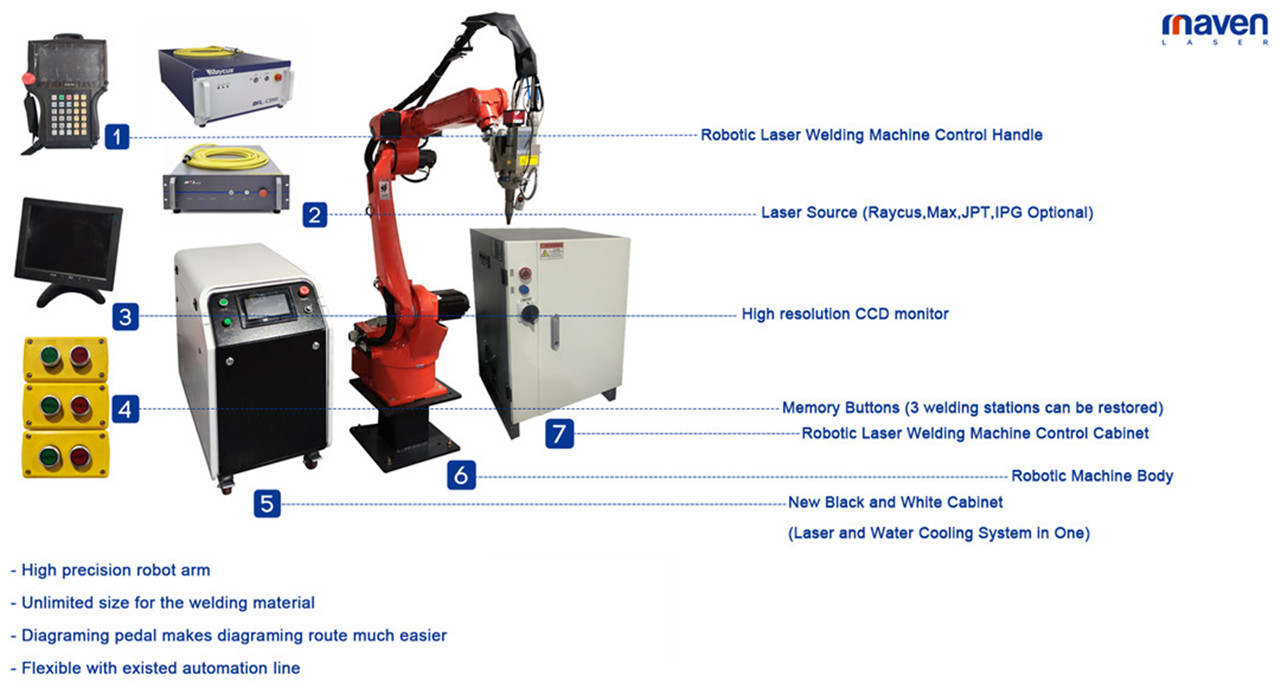

● Laser Source(Raycus,Max,JPT,IPG Optional)

● High resolution CCD monitor

● Memory Buttons(3 welding stations can be restored)

● New Black and White Cabinet(Laser and Water Cooling System in One)

● Robotic Machine Body

● Robotic Laser Welding Machine Control Cabinet

● High precision robot arm

● Unlimited size for the welding material

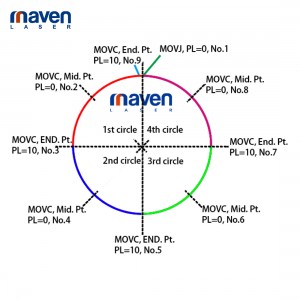

● Diagramming pedal makes diagramming route much easier

● Flexible with existed automation line

|

MLA-W-A01 |

MLA-WA02 |

|

|

Controller |

6 |

5 |

|

Max Lead Capacity |

10 |

10 |

|

Rea(mm) |

1468 |

1468 |

|

Repeatability |

±0.08 |

±0.08 |

|

Motion Range(°) |

||

|

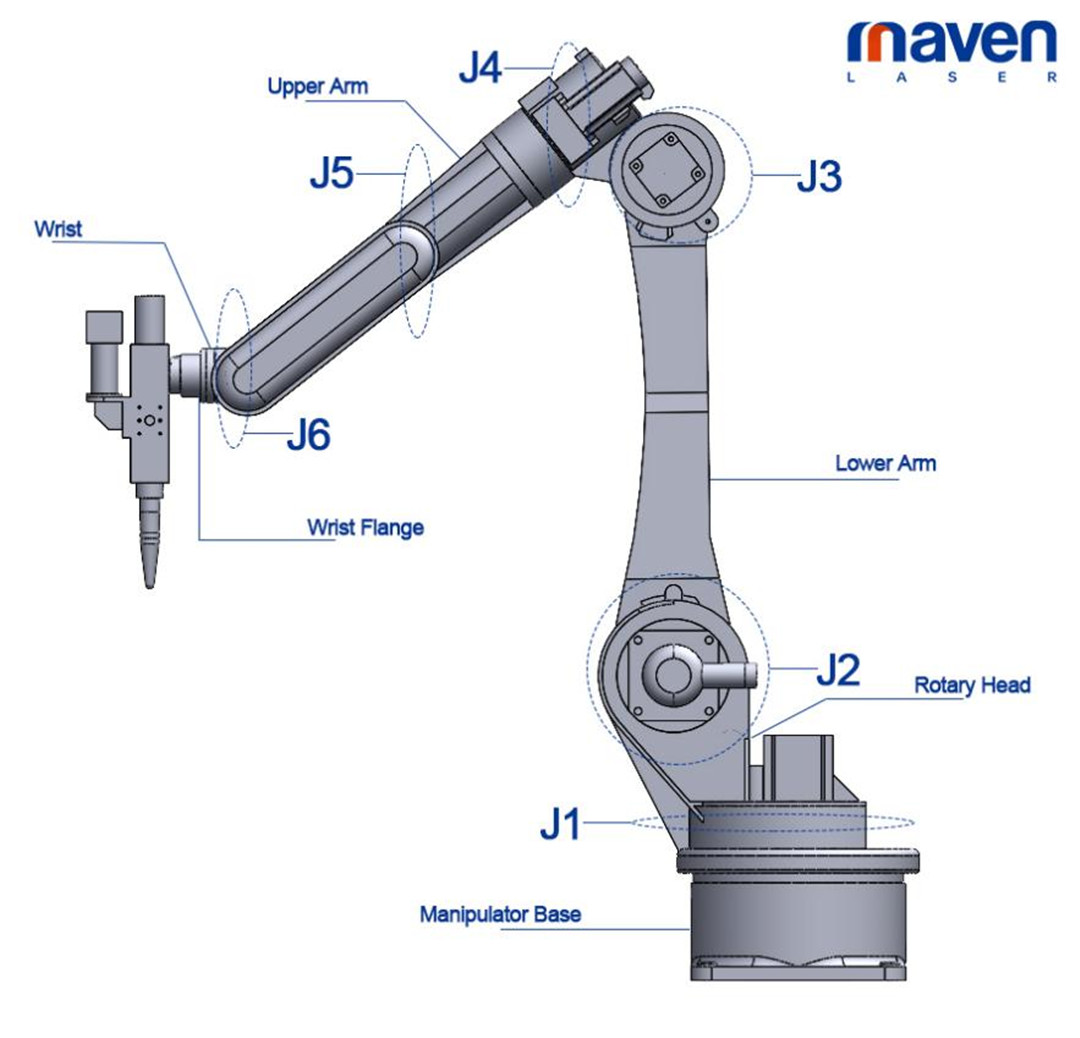

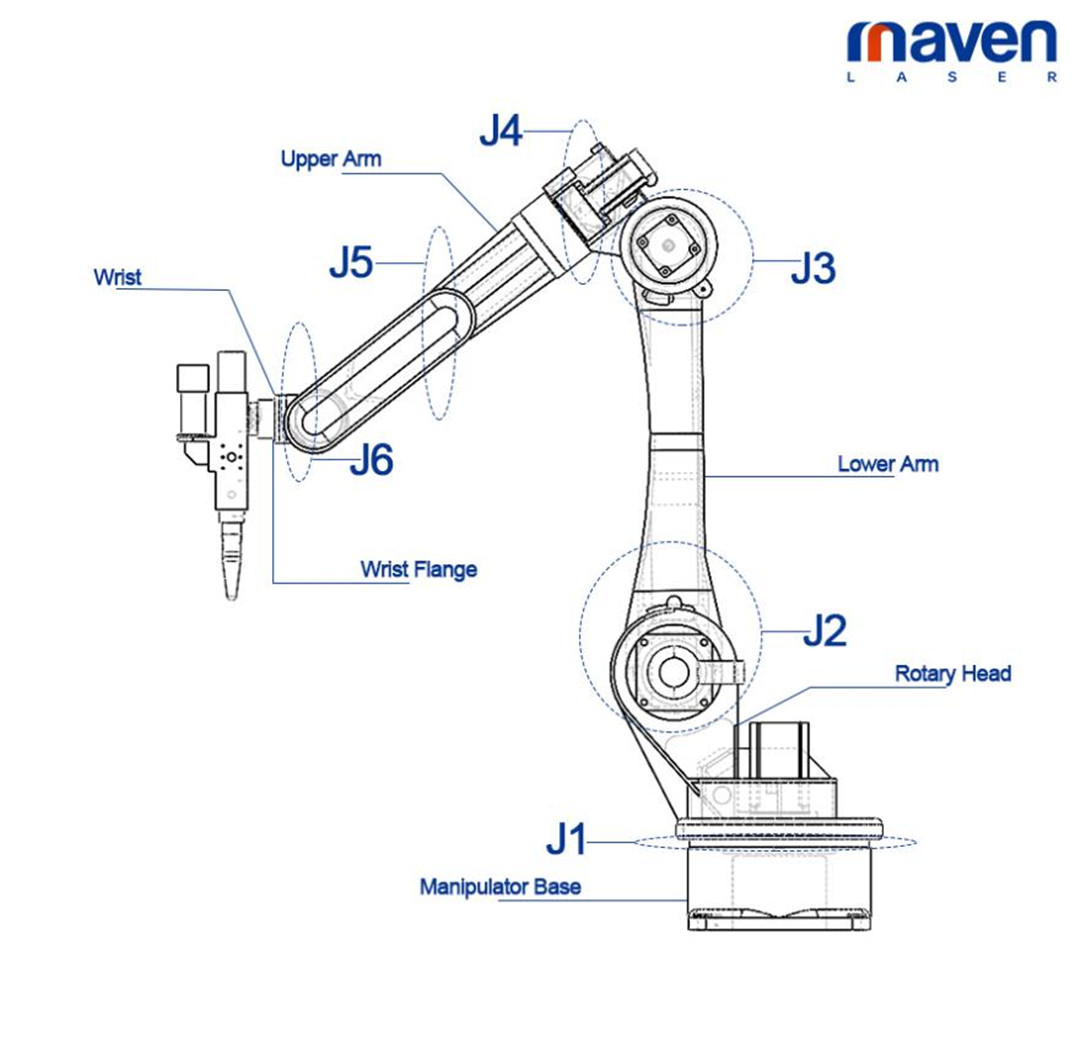

J1 Axis |

±170 |

±170 |

|

J2 Axis |

±80~-90 |

±80~-90 |

|

J3 Axis |

±85~-90 |

±85~-90 |

|

J4 Axis |

±180 |

|

|

J5 Axis |

±130~-105 |

±130~-105 |

|

J6 Axis |

±350 |

±350 |

|

Max. Speed(°/s) |

||

|

J1 Axis |

190 |

190 |

|

J2 Axis |

140 |

140 |

|

J3 Axis |

140 |

140 |

|

J4 Axis |

220 |

|

|

J5 Axis |

150 |

150 |

|

J6 Axis |

320 |

320 |

|

Control Cabinet |

||

|

Type A1 or Type A2 |

||

|

Mechanical Weight(kg) |

||

|

|

161 |

159 |

|

Installation Conditions |

||

|

Ground,Inverted,Slide-mounted |

||

|

Operating Conditions |

||

Ambient Temperature:0-40℃

Ambient Humidity: Usually below 75%RH(no frost phenomenon), below 90%RH for short term(within 1 month)

Vibration Acceleration::4.9 m/s2(0.5G) or less

Note:1.the maximum speed of each axis may not be reached when moving over short distances.

2.Please specify when ordering upside down or side mounted

1. Mode Switch

2. Emergency Stop

3. Display Screen

4. Physical Keys

5. MPG (Manuel Pulse Generator)

6. Enabling Device